It’s not that many years ago that MEMS devices were regarded as something of a novelty, with early applications focused mainly in the automotive industry – airbag deployment, for example.

Fast forward to today and it’s hard to avoid MEMS technology. Mobile phones are an obvious example – housing motion sensors, gyroscopes microphones and speakers – while automotive MEMS can also be found in braking systems, emissions control and navigation. And opportunities for MEMS devices are appearing in many other applications, such biomedical sensors and drug delivery systems. It could be argued that wearable devices wouldn’t have taken off without the benefit of MEMS.

MEMS technology has been championed over the last few years by the MEMS Industry Group (MIG), which was recently absorbed into SEMI, the electronics supply chain organisation.

Karen Lightman, previously managing director of MIG and now vice president of SEMI’s MEMS and Sensors Industry Group, told New Electronics in 2012 that she believed innovation in the MEMS market relates to the way the technology is applied, rather than development of the technology itself. “What MEMS is doing,” Lightman noted, “is allowing designers to realise functionality which they have always wanted in their products.”

And the extent to which MEMS technology is pervading all kinds of industry is highlighted by the annual Technology Showcase, being held this year at the beginning of November alongside the MEMS and Sensors Executive Congress.

“This year’s Technology Showcase finalists are as fascinating as they are diverse,” said Frank Shemansky, SEMI’s CTO. “Imagine, for example, a MEMS-based switching element enabling RF switching that is 1000 times faster and lasts 1000 times longer than traditional mechanical switches. That is the kind of MEMS technology that could improve wireless applications dramatically and is just one of the Tech Showcase finalists – and the others are equally compelling.

“The Tech Showcase is always a big draw at the Executive Congress because it gives attendees the chance to interact with the finalists’ demos to decide their vote for the winner – one of whom will be ‘crowned’ at the close of the conference.”

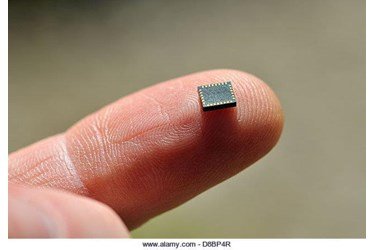

The five finalists this year are: LEIF Technologies, with its eSnowboard; the Maven Co-Pilot by Maven Machines; and Menlo Micro’s Digital Micro Switch (DMS) technology. Also shortlisted are eLichens’ Berries Smart Sensor series of autonomous non-dispersive infrared gas sensors. These miniaturised optical gas sensors are systems in a package integrating an infrared MEMS emitter and detector, an optical sampling chamber and signal processing; and PZFlex’ Coupled Time Domain Simulation for MEMS Sensors and System Integration by PZFlex, which enables modelling and simulation in new MEMS application areas.

Russ Garcia, CEO of Menlo Micro, said the company can trace its heritage back to 2004. “Engineers at General Electric – which was then a power company – wanted to make remotely programmable circuit breakers for energy management applications. They weren’t planning to make MEMS devices; rather, they wanted to source them. The engineers started to look at MEMS failure mechanisms and found one of the major problems was materials fatigue, rather than stiction. They asked what should the material be to get the results they wanted, such as reliability and electrical performance and had to invent new alloys. Having invested $40million, GE spun out the technology as Menlo Micro.”

I'm studying to be an electronics engineer, and this article was very helpfull.