Greetings steemians!

It’s a lovely and cool night here and i just watched liverpool's awesome performance against Roma at Anfield. It’s a pity my team is no more in the champions league. Please don’t ask me which team I support. All I know is that I support one of the successful teams in the world.

By the way, I hope you had a great day and I want to believe that you have always enjoyed reading through my articles. Please, always let me know what you feel.

Today its gonna be another Automobile article.

The last time, I discussed the Automobile Cooling system. This time around, I will like to talk about a system that has brought comfort to our driving – The Power-assisted Steering System.

Let me start here!

The average weight of a bag of cement is 50 kg (sorry if I am wrong about it in your country but that’s what it is here in Nigeria). I can hardly lift this bag of cement and even if I do I can hardly go past a meter before dropping it – yeah, I am that lazy.

If I ask you to twist this bag of cement on a spot about its center like you will turn the steering wheel, for how long can you carry on?

The weight of a car can range from about 1800 – 6500 pounds (that’s approximately 690 – 2950 kg in the SI system of units). The car rest’s on the wheels and exerts its weight on it and forces the wheel firmly to the ground. The only link between you and the wheels you want to steer is the steering wheel.

I don’t know how long you could have endured twisting the bag of cement, but I am sure you cannot do that for long. Imagine the stress you will go through twisting a bag of cement exerting a downward force of 50 x 10 = 500 N (I’m approximating the value of gravitational acceleration as 10 ms-2).

Now compare this to twisting two wheels (tyre) that are forced down by a force of at least 690 x 10 = 6900 N. That’s a lot of force. I have not even taken into consideration the weight of the wheels (tyre + rim) themselves.

Well, I wouldn’t know how tedious it is to steer cars without power steering system (as it was long long ago), but I have certainly driven that which uses power steering but failed while I was driving. I was lucky enough as I was off-road. What I am telling you is that even if I don’t know much about the cars of the old, I know how tough it is to steer a car without any augmentation.

Now let’s stop the preamble here and look at what makes up the power steering system in your car. However, let’s briefly see how the steering system looks like without any assist component.

BRIEF NOTE ON STEERING SYSTEM

The steering system in an automobile is a system that enables the vehicle to be maneuvered in a driver’s desired direction, by altering the angle of the front wheels accordingly (it could interest you to note that there are cars in which you could steer the four wheels, but that’s not for today). This is achieved by converting the rotary motion of a steering wheel handled by the driver into an angular turn of the front wheels.

Let's look at the setup.

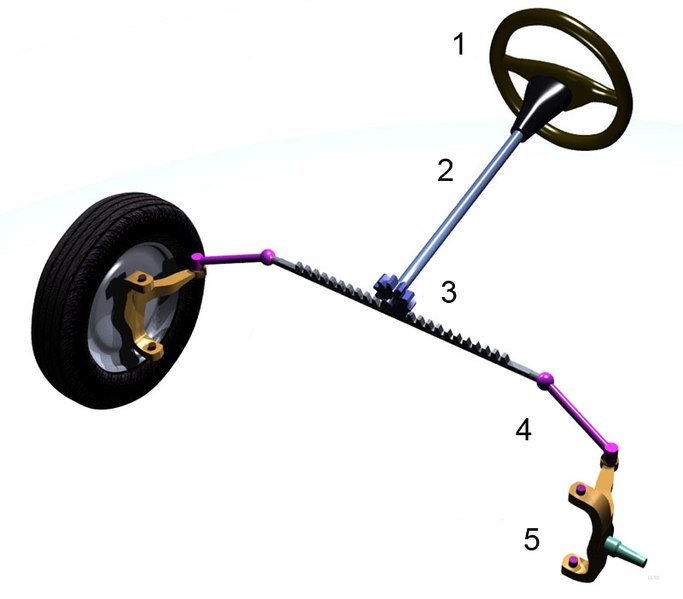

One notable component of the steering wheel is the steering gear, which performs the function of converting the rotary motion of the steering wheel to linear motion. The steering gear is usually a Rack and Pinion gear set, although there are other types. A simple setup of the steering system is shown in the image on the left.

Let’s name the components.

1 – Steering wheel, 2 – Steering shaft, 3 – Steering gear (rack and pinion), 4 – Linkages (called tie-rods), 5 – Steering Knuckle.

The rotary motion of the steering is relayed to the pinion (the circular piece with teeth shown). This pinion in turn relays its motion to the rack (the horizontal rod with teeth) and thus the rotary motion becomes converted into linear motion.

The front wheels are connected through linkages to the rest of the steering system and pivot usually on two joints (the upper and lower Ball Joint) on the steering knuckle. These joints form the steering axis about which the wheels turn. To make it clearer, the steering axis is the line drawn through the upper and lower pivot points of a steering knuckle.

When the linkages are moved by the steering rack, by virture of the rotatable end joints, they are able to casue the angular movemnt of the road wheels depending on the direction in which the steering wheel is steered.

Now let’s move on to the main discussion.

Power assisted steering systems employs various kind of mechanism to achieve the said objective. The earlier ones depended on hydraulics (the use of oils). Today, the evolution of the automobile industry has brought about having more of electrical control system in an automobile and this includes the power assisted steering. However, the hydraulic power steerings are still very much relavant today.

Whether a power assisted steering completely depends on hydraulics or utilizes electrical mechanism, their function is the same - they all reduce the effort in which a driver applies while steering the wheels.

HYDRAULIC POWER-ASSISTED STEERING

A Hydraulic Power-assisted steering is a steering system in which hydraulic pressure is used to increase the steering force thereby reducing the effort of the driver. This is of great use because it eases the steering control, and improves vehicle handling (this would be clearer when i discuss how the system operates).

A typical power steering system requires a force equivalent to about 1.5 kg. Thats what i call comfort.

Hydraulic system is employed due to the fact that liquids are able to transmit forces around obstacles, bends and pipes as well as due to their incompressible nature which allows them to be perfect for transmitting forces like solids do. @adetola recently authored an article on the hydraulics. You should check it out.

COMPONENTS OF A HYDRAULIC POWER-ASSISTED STEERING

The following are the components of Hydraulic Power-assisted steering;

- Power steering pump (the heart of the system)

In Power steering systems, to achieve a force enough to ease the driver’s effort requires that the fluid be pressurized to a high pressure. A typical value of such pressure is around 1500 psi. This can only be achieved using a pump - the power steering pump. The power steering pump are usually belt-driven by the engine via a belt from the crankshaft pulley to a pulley attached to them. Power steering pumps come in many sizes and designs depending on the vehicle make and model.

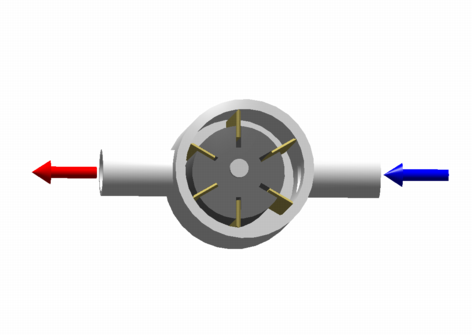

Most power steering pumps are of the retractable-vane type (a type of rotary positive displacement pump) with a drive pulley fitted to a chrome-plated shaft. Splined to this shaft inside the pump’s casing, is a rotor with sliding or retractable vanes, which rotates between an oval-shaped cam ring and pressure plate. A simple diagram is shown just above to the right.

Let me recap to make things clearer in simple sentences.

We need rotational force to operate the pumping element (a disk with retractable-vanes within a oval-shaped enclosure) of the power steering pump. We will derive this rotation from the crankshaft. The crankshaft will then drive a pulley using a belt. This pulley is connected to a shaft which then drives this pumping element. I hope you dig now?

Lets move on.

When the pump is driven the shaft rotates the rotor and centrifugal force pushes the vane outwards causing them to make contact with the interior of the cam ring as they rotate. The shape of the cam ring causes a variation between pressure and volume in the pump. Looks like you don't get it.

At the inlet of the pump, the area between the rotor and the cam ring is large, thus volume is large as well. This results in low pressure (due to pressure - volume inverse relation) which causes the suction of fluid at the pump inlet port. The fluid admitted becomes trapped between the vanes and the wall of the cam ring and is pushed along the direction of rotation. The volume where the fluid is trapped becomes smaller as the vane rotate further and pressure increases along the line. At the pump outlet port, the volume becomes least and the pressure of the fluid is greatest. High pressure fluid is then discharged through the outlet port.

Let me take a deep sigh… Alright let’s go on.

- Power Steering Fluid Reservoir

Hydraulic Power steering system are equipped with a Fluid Reservoir that holds the power steering fluid and keeps the pump in constant supply of fluid. The power steering fluid Reservoir is usually made of plastic and contains the fluid filler neck, Cap and dipstick.

Some reservoir are made as an integral part of the power steering pump (this I have seen in Mercedes Benz) and the pump itself operates submerged in the power steering fluid. Most reservoirs are remotely mounted, with the pump constantly fed through a rubber hose.

Hoses

The Power steering gear is supplied with power steering fluid through steel hoses. The outlet hose is high-pressure hose (pump supply line) with fittings that screws into a threaded hole at the outlet port of the power steering pump. Another hose, a low pressure hose returns the fluid from the steering gear to the fluid reservoir. In some vehicles, the return line has a cooler in its path to cool the power steering fluid before reuse.Power Steering Gear

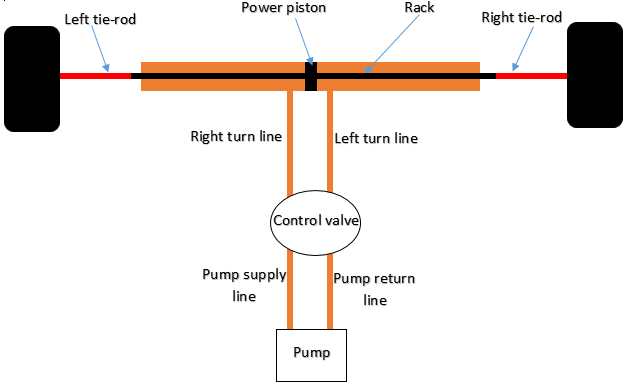

Power steering gears in Hydraulic Power steering system are simply a conventional power steering gear (mostly today they are Rack and Pinion type) in which some add-ons to fulfil the function of power-assist are incorporated. The add-ons majorly includes a Control valve and a Power piston connected to the steering rack. The control valve regulates the application of Hydraulic pressure to this Power piston which in turn moves the output gear – the rack.

You will understand this portion better in the next section.

THE OPERATION OF A HYDRAULIC POWER-ASSISTED STEERING

.png)

Now that we have seen the major components of the hydraulic power steering. Let’s see they come together to make the system work. The operation of the hydraulic power steering system will be explained using the above schematic.

I am going to explain the operation based on the three possibilities (or positions) that could occur while steering which are:

- Having the steering in the neutral position, i.e. neither turned left nor right.

- Steering turned left.

- Steering turned right.

Note: In all cases, so long the engine is running, the power steering pump is also running. Another point to be noted is that the control valve is instrumental here and at the forefront of all this operation.

When the steering is the in neutral position, the power steering fluid travel out of the pump into the control valve and returns to the pump without going through the left-turn route or the right-turn route. Consequently, no assist is provided.

When the driver steers left, the power steering fluid travels through the supply line into the control valve. By virtue of the design of the control valve, the fluid is routed through the left-turn line and pushes against the power piston. At the same time, the fluid is expelled from opposite side of the piston through the right-turn line. Consequently, the rack is pushed to the left and the driver is assisted.

When the driver steers right, similar situation happens as in the case of left turn. The control valve routes the fluid through the right-turn line and fluid is expelled through the left-turn line. As a result of these, the rack is pushed to the right and the driver is assisted.

We have seen how the hydraulic power steering system functions. Now let's look at the modifications that have been introduced.

VARIABLE ASSIST POWER STEERING

At low speeds, such as when parking, the vehicle’s weight is predominant and thus the steering wheel is always difficult to turn, unlike at high speed where the vehicle’s weight is less dominating and thus the steering wheel is easy to turn. Due to these facts maximum power assist should be rendered at low speed and less assist is needed at high speed.

However as the speed of the engine increases so does the speed of the power steering pump. As a result of this, more power assist is rendered at high speed which makes steering feels loss and less stable. Hence, there is need for a system that can sense the speed of the vehicle and use this information to provide assist accordingly such that the steering wheel is easily maneuvered at low speed and there exist a good road feel and steering stability at high speeds.

This type of power steering system is called the variable-assist power steering. Various manufacturers have designed various forms of variable-assist power steering, to meet this demand with each manufacturer naming his design in his own words. These systems may be different in construction and design but all have similar outcome. Example of such is Magnasteer by General Motors.

ELECTRONIC POWER STEERING

In Electronic Power steering systems, the use of a Hydraulic system is excluded. Instead an Electric motor is used to provide the required power assist. The electric motor may be connected to the steering column or the steering gear, depending on the vehicle make and model. Electronic Power steering system has phased out the use of Hydraulic system in latest cars.

It has advantage over the hydraulic system in that if the engine stalls, power assist will still be available since the system is powered by the car battery. Although if the system should shut-off while the engine is still running, power assist will be lost. However, the system does not eliminate the mechanical linkages from the steering wheels to the drive wheels, which will ensure that the vehicle can still be steered but it will have to be done manually.

The steering wheel in this case will feel heavier to the driver. The maneuverability of the car at this stage now falls solely on the skill of the driver. Since the EPS eliminates the use of Engine-driven hydraulic pumps, the engine suffers less power drain and can run more efficiently. The use of hoses and reservoir is also excluded.

Electronic Power steering systems varies in design and complexity which depends on the manufacturer and model of the vehicle. However, an EPS system usually includes a steering wheel torque sensor, steering wheel position sensor, power steering motor and Power steering control module (PSCM) in addition to the existing steering wheel, column, gear and linkages.

The steering wheel torque sensor and position sensor are usually mounted together on the steering column. The Torque sensor detect the torque applied on the steering wheel as well as the direction being steered. The more the torque applied on the steering wheel, the higher the voltage signal generated by the torque sensor.

The voltage signal from the torque sensor is the main input for the power steering control module. The PSCM combines this main input with other inputs, such as the vehicle speed (from the Engine control module) and steering position sensor (from the steering wheel speed sensor) to determine the amount of steering assist needed and the direction to which it is required. A corresponding amperage is then sent to the power steering motor which provides the assist accordingly.

ELECTRO-HYDRAULIC POWER STEERING

Electro-Hydraulic power steering is a Hybrid system, combining the Electronic Power steering and Hydraulic power steering. It employs a Hydraulic pump (as in a Hydraulic power steering), that is driven by an electric motor (as in an Electronic Power steering).

This system has a control module called the Electro-Hydraulic Power steering (EHPS) control Module, which oversees the operation of this system. It gathers input from various sensors and regulates the current to the motor accordingly.

It has an advantage in that it reduces engine drag since the pump is driven by an electric motor. It also has the ability to improve fuel economy by operating on a demand basis and the ability to provide speed-dependent variable-effort steering.

CONCLUSION

The power steering system is a system that provides comfort while steering. Steerings are so easy to turn to the extent that you can turn them with you fingertip (that’s not an exaggeration).

The advent of electronic control system in the automotive industry has seen the augmentation of the hydraulic power steering with some electronic devices. And even now, most cars utilize fully electronic power assisted steering. The use of Electro-Hydraulic power steerings provides a compromise between the Hydraulic and Electronic power steering.

If you have ever driven a car with a faulty power steering system, I am sure you know the worth of this system. Otherwise, picture yourself twisting some bags of cement, then you will get the drift.

Thank you for being her once again.

REFERENCES

- Halderman, J. D. Automotive Technology - Principles, Diagnosis and Services. (Fourth Edition)

- List of Car Weights

- Variable Assist Power steering

- Electronic Power Steering

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Once again the gears come to play here.. Not for getting the hydraulic system.

I had always wondered how the car steering worked tho and the way it rotates freely marveled me till i went through this... Thanks for the education.

My pleasure

If only Roma could have power steered themselves to a victory.

Thanks for this eye opener post.

Well, I think Liverpool deserves some accolades. Thanks for dropping by.

You are most welcome.

Hydraulics and gear system are just too functional. Guess steemit is where I'll eventually learn the automobile part of my "Mechanical Engineering" course.

Thanks for this succinct article

Steemit through @steemstem and @stemng has given us the platform to educate and be educated... It is my pleasure to play my part.

We will always be grateful to @greenrun and @gentleshaid for their relentless effort. The entire steemSTEM community and crew are not left out either.

Exactly bro. Let's keep repping

If you take time to watch those drivers that drive heavy duty manual vehicles struggle with the steering, it will make you realize how important having a power steering in your car is. Quite an informative article @temitayo-pelumi

Actually, the duty trucks are fitted with Power assist as well. In fact, it is more needed in them than our regular light vehicles. It's crazy how tough it is to steer them with the assist. Thanks for dropping by.

I once had a power steering system fail on me. That was a hard drive afterwards.

Glad to hear that the electric assist systems are superior to the hydraulic systems because that is what my current vehicle has.

Thanks for sharing your experience. I drove a car as well with a malfunctioning power assist. It took me a great deal of effort to make a U-turn on a narrow road. Electrical control systems are becoming more popular in cars and are really making waves.

Thanks again for dropping by.

Not all electric assists are better.

The battery died in my car on a torrid day of summer and when I jumpstarted it, I had no electro-hydraulic steering. It was harder than on a car with no hydraulic system in the first place since you have to also compress the oil in the hydraulic system to steer, or maybe @temitayo-pelumi knows better :D

Anyway, it was impossible to drive through rush hour traffic so I backed it up and called for a platform.

Congratulations for such an amazing post, top notch!

About the subject in question, I don't think manual steering would be a thing in the decades to come, autopilot will be the new normal in my opinion.

off topic: I saw you mentioned the Champions league match :), I saw it too, bad for Liverpool those 2 goals at the end but still 5-2 is not bad. I don't think Roma can repeat what they did to Barcelona.

Speaking of technological revolution, the Automotive industry is one leading area. Therefore, I couldn't agree more.

About Liverpool, I think they are going for the kill. I don't Roma could repeat what they did at Barcelona because Liverpool is really hungry at the moment. However, let's keep our fingers crossed, as only time will tell.

Thanks for the kinds words, it an honor to have you here.

power assisted steering is one way technology brings comfort to us.

Well written sir!

Thanks!

As much as I thought I'm familiar with the Power steering system, I certainly didn't know about the Electronic Control system. They sure save us a lot of sweat. I remember a comedian once saying "there is difference between Power Steering and Powerful Steering" 😂. I suppose we have all been saved from driving "powerful steering". Great article you have here. Always detailed.

Lol... It is really a Powerful steering without the power assist. Thanks for dropping by, I'm glad you learned something.

Another of your well written articles. I really appreciate more engineering posts, there were not many of those a while back. Keep writing and don't forget to include other articles when you just mention a subject but don't want to get deep with explaininations.

Hey Alex, thanks for dropping by and thanks for the heads up.

I am actually picturing myself twisting a bag of cement, and it isn't funny. Power steering system has surely made driving a lot easier. Thanks for the post.

Thanks for being thoughful.