Imagine you got a job in a manufacturing company and your job role was simply to tighten a screw on Fans after Fans, day after day, for week, months and years.

How effective do you think you would be after doing this job for a month?

Overtime this repetitive job gets so routine, tiring, unfulfilling, and then mistakes starts happening and your productivity eventually decreases. I bet you agree with me that there are just some tasks that are better performed by programmed robots than by humans. Robots are excellent tools to get things done in a consistent, predictable and precise manner.

Robots came on board as efficient replacement for humans, to handle extremely difficult, precise, dangerous repetitive tasks in various fields. Unlike humans Robots don’t get bored, distracted, require days off, doesn’t complain and mistakes rarely occurs. Robots are widely used because they are more efficient and relatively cheaper to use than humans.

The importance of robots to mankind cannot be overemphasized, sometimes robots are practically the only possible means of accomplishing some herculean tasks like exploring other planets or places in the universe that have extreme temperatures or contamination not conducive for humans, explorations of volcanoes, deep sea exploration, gas tanks, the list is endless.

Robots are the backbone of various manufacturing industries and without them certain tasks cannot be undertaken effectively. For instance, in manufacturing industries Robots are programmed to drill holes exactly in the same spot on each units and tightens bolts consistently to the same level with the exact same force and the robots accomplish this swiftly and effortlessly. Furthermore, the precision required to manufacture a tiny microchip is so immense that it requires a robot to perform this operation.

They are also effectively utilized by the military for major operations such as reconnaissance, bomb detection, surveillance and delivery of supplies. You can find mobile robots in homes, offices, laboratories all working to make life easier for mankind.

Today I would be focusing on the basics of robotics.

I like to refer to robots as reprogrammable automatic or remote controlled man made machines that were built to perform work or other actions that is normally performed by humans. They can simply replicate human or animal behavior. Hence robotics is simply the science and study of robots. Generally, robots have different level of sophistication and functions, however they all have some basic similarities.

Robots have a physical structure that is movable, some require motorized wheels while some have several movable segments which are built with metals and plastics, this segments are joined together with joints. Typically for robots to pivot the jointed segment they spin their wheel, this is achieved by making use of actuator. The actuators required by the robots differ depending on the type of robot, while some utilize electric motors and solenoids, others function using hydraulic system or some function making use of systems driven by compressed gas known as pneumatic systems. Robots might utilize either of these methods while some sophisticated robots combine the use of the three to function optimally.

The actuators cannot function effectively without power supply. Depending on the type of robot they can derive power from batteries or they can be plugged directly into a socket. There is an electric circuit in robots that performs the role of transferring energy to the electrical motors and solenoid directly and operates the electrical valves to control the hydraulic systems.

Everything connected to the circuits within the robots are controlled by a computer. Typically, robot can be reprogrammed, so for the behavior and function of the robot to be changed a new program is simply written. The computer is responsible for monitoring and switching the valves as well as the motors to carry out the required actions for the robot to make movements.

Depending on the type of robots, some are built with relevant sensors, these sensors could facilitate the robots sight, smell, movement ability to hear and determine size, shape. Amongst all this sensor the ability for the robot to move effectively is the most peculiar sensory system common to majority of them. Some Robots can be very simple and have straightforward operations and some can utilize all this elements in a tremendous way to make up a robot with unlimited complexity.

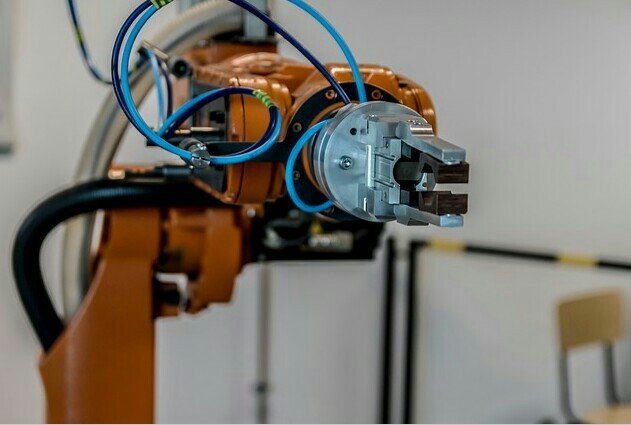

Let’s take a look at Robotic arms

When it comes to manufacturing one of the robots that cuts across several fields is the robotic arm. Generally, when you take a look at a robotic arm you would notice it comprise of 7 metal segments which are joined together by 6 joints. These joints are connected to separate step motors which are controlled by the computer to rotate them when performing tasks, however in some cases pneumatic systems could be utilized as well hydraulic systems are used for relatively larger robotic arms.

Step motors are used in robotic arms because they facilitate the very precise and repetitive movements of the robotic arms due to the fact that step motors move in exact increments. While the robotic arm continuously performs the programmed action, there are motion sensors installed to ensure that there is no deviation in the movement and sequence.

Similarly, the function of your arm is for the movement of your hand, and that is exactly what the robotic arm does, it basically moves an end effector from one location to another. Depending on the function of the robot, the end effectors on the robotic arm can be changed to suit the application. some end effectors include spray painters, drills and blowtorches. One of the most popular end factor in industries is a sort of simplified version of hand that grasp and carry different items. This hands come with sensors that determines and ensures the items are gripped by the robotic arm and ensures the robot doesn’t drop or break the item by applying too much pressure when carrying the items.

A Robot is taught how to carry out an action by programmers in a controlled environment by guiding the machine through the motions using controller and during this process the robot takes in this information and stores it in its memory. Then the robot can perform the exact sequence of movement continuously on the assembly line as new units comes down.

Robots are vital in the manufacturing of cars because of their precision and consistent efficiency.

There are a vast majority of robotic arms, so a typical robot used in industries that has 6 joints would be able to pivot six different ways. Its relatively easier to build and program robotic arms mainly because they function within a confined area unlike robots that do not function within a confined area that require a more complex design.

Movement of robots

During the designing of a mobile robot, the designer would have to make sure the robot is built with a locomotion system that would be suitable for its function. For instance, if a robot’s movement would mainly be on a smooth surface then the designer would incorporate a wheel or track for this type of robot and similarly if the robot’s movement includes rough terrains a larger wheel or track could also be used.

For robots to move back and forth hydraulic or pneumatic piston are connected to different segments of the leg, the robot designer programs the robot with the right combination of piston movements that would be required for walking. During manufacturing of robots a balance system is incorporated in it to ensure the robot can correct itself if the need arise.

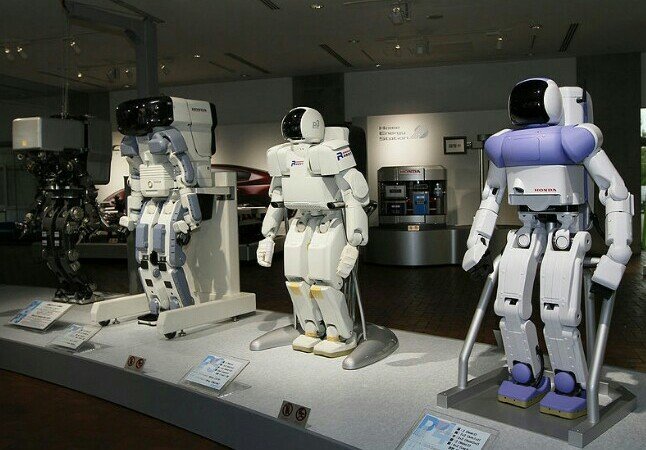

In recent times a number of robots have being built that can walk using two legs known as the bipedal locomotion but this type of movement is quite unstable and relatively hard to implement effectively. So designers prefer to use a more stable 6 legged robots which can easily adapt to a wide range of terrains.

There are robots that are controlled by remotes which could be fully or partially controlled by humans that communicate with the robot through an attached cable, radio signal or infrared signals. These type of robots are extremely useful especially for accessing inaccessible and dangerous environments such as bomb detection scenario, volcanoes, or deep ocean exploration. The partially and fully controlled robot function differently, for instance in the partially controlled robots the operator simply gives the robot directions but do not steer it to the location, the robot performs that by itself.

Autonomous Robots

Autonomous Robots do not require controllers to operate effectively. One of the major users of this robots are the military which use them for urban operations to explore and gain information as well as rescue troops. This kind of robots is programmed to respond to specific external stimuli in a specified way. The sensors make them more efficient and smarter so they can navigate several environments effortlessly, these sensors help them detect obstacles so they can act accordingly. The sensors vary depending on the sophistication of the robots, less complicated robots could utilize either ultrasound sensors or infrared sensor while some advanced robots make use of stereo vision.

Some autonomous robots are manufactured to work strictly in familiar and constrained environment but some very advanced autonomous robots can adapt to rough and unfamiliar terrain by analyzing and then taking actions. A rover robot is a typical example, it maps out the land in front of it using its visual sensor, analyses the map and if the analysis shows that it the terrain is rough and bumpy, it changes direction and takes another route. This is a superb tool for exploring other planets.

CONCLUSION

A vast majority of people complain that robots are gradually taking jobs away from humans, making us obsolete. But the truth is the fact that robots can be programmed to automate repetitive operations have been quite favorable and have contributed greatly to the efficiency of certain industries. In some industries humans don’t have to be present to perform certain tasks because robots consistently perform this tasks efficiently, so humans can increasingly have more time to focus on more creative and productive tasks. Additionally, Artificial intelligence has also contributed immensely to how robots process information and learn and With the massive investment in robotics technology we would have more robots that automate workplace operations in the future.

REFERENCES

The complete History & Future of Robots

Robotics & Artificial intelligence

Your blog is very informative we promoted your blog and your name on our steemit Instagram community here is a link https://www.instagram.com/p/BmIOLHVAahY/?utm_source=ig_web_copy_link

Have a great day ahead.

This post has been voted on by the steemstem curation team and voting trail.

There is more to SteemSTEM than just writing posts, check here for some more tips on being a community member. You can also join our discord here to get to know the rest of the community!

Hi @steematlas!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV