What comes to your mind when you hear the word wear?

My search for what this word on google led me to different definitions of this simple four letter word. And in the context which it was defined did not even come close to what I was looking for. If you are just a layman who made the search on google you would be contented with what you have just found on the first page which was just talking about how you put on clothes.

Don’t get me wrong wear can be used in that context some sites even went as far as what would Meghan wear to the royal wedding. Lol

Well if you are a mechanical engineer, you would consider all that as just junks as they are nothing related to our field. This four-letter word is simply my interest today and I take it upon myself to make sure that any layman searching for this word will have to see my steemit link and get a simplified view or opinion of what mechanical wear really is.

Mechanical wear

If you did high school physics when your teacher was talking about friction I am very much sure he/she must have discussed wear as they go side by side. But there are certain things your teacher didn’t tell you about wear.

did you know wear could be caused by fluids?

I would like you to pick up a blunt pencil and look for a brick wall nearby please do not use a painted or wooden wall. You might as well damage the painted wall while carrying out this little task. Now place the edge of the pencil and rub repeatedly against the wall.

I am very sure many of us did this very well in elementary and high school when we had no pencil sharpener or blade to do this task. Well, the result of this little task is that the wood on the pencil reduces till you can finally access the lead inside the pencil.

Well, this does not mean the wall is a pencil sharpener it means that the part one repeatedly rubbed against the wall reduces entirely. And this does not explain how the pencil sharpener works but rather says one thing about the effect of rubbing two rough surfaces on each other this effect is what is term mechanical wear.

Wear and heat as partners for friction

We can say that friction and wear are brothers and they go hand in hand. if you remember in our little task earlier. Two contact surfaces (the pencil and the brick wall) were involved and not forgetting that in the process of rubbing those things together the first effect is heat and what you notice is that one edge of the pencil starts to reduce.

But this pencil and wall test we carried out was intentional and we, of course, did with a sound mind which led to the gradual removal of the wood around the pencil. What then happens if you never wanted it to happen or you didn’t carry out the experiment and it just keeps happening?

This would be annoying right?

Now this sounds like wear, Just like in agriculture where weed is an unwanted plant, wear is an unintentional and stage by stage removal or indentation of a solid surface which can either be caused by the chemical or mechanical action.

You must be wondering chemical? yeah, you read that right and the chemical action of wear is caused by corrosion while the mechanical causes are simply termed erosion.

Have you wondered why your engine always say “do not start without an engine oil”?

This unintentional and stage by stage removal of the material surface could lead to what is called fatigue and finally failure of the machine part. This is why your engine would totally fail without engine oil in it. And one funny thing about wear is, you might not get to see the metal part removed with your physical eye.

Corrosion

My lecturer of cause called corrosion the unintentional attack on the environment with a metal surface.

Well, you might call that crazy, but it is true, the environment sometimes just looks at a metal and becomes jealous and be like hey let’s fight?

Well not like fight physically but in chemical reactions and for chemical reactions to occur elements has to be involved which are simply air and water. I read about corrosion by @temitayo-pelumi and it is well detailed on his blog it can be found here. Don’t let me wear you out before you complete this article. Lol

Erosion

In geography, erosion is simply called removal or gradual process by which the topsoil is removed by wind or water as the main culprit of this action and of course, it is unintentional too. But this is geography and not engineering so the water and wind action does not really apply to material surface. The erosion, in this case, is caused by another solid material just like the wall was the main culprit in our little test.

The study of wear and friction as we are doing right now is termed tribology in engineering. But from what we deduce the action of different surfaces on other surfaces (for example, sliding mild steel over mild steel isn’t going to have the same effect as pencil on a wall) although both will lead to wear the rates, debris, heat, and effect wouldn’t give us the same thing. This leads us to the different types of mechanical wear.

Types of wear

If you were patient enough to read my last paragraph I mentioned something about the reaction gotten from the movement of two mild steel in contact cannot be the same as that of two wood surfaces in contact and of course, it definitely wouldn’t be the same as a wood on a mild steel surface or a tyre on a road.

This brings us to the discussion of the types of wear that we have, and I am going to do my best in explaining every type of wear.

The abrasive wear

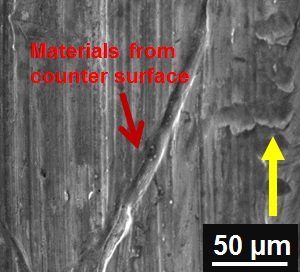

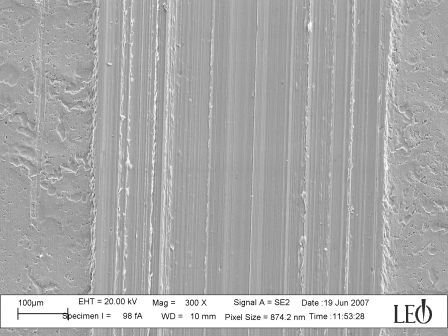

If you have a smooth metal surface like aluminum and its kept in the open for long, there is a possibility of that surface to react with the environment and form some lumps on it. These lumps formed on the surface of the aluminum is what is known as asperities. In abrasive wear, we deal with what is known as the reaction between two asperities surface not forgetting contact is needed for this type of wear to occur.

Now if you place two surfaces with asperities on each other with the asperities in contact, there might be a possibility of nothing happening till a load is placed on one of the surfaces, meaning one on the surface will have its asperities broken and if they are slid across each other little asperities formed on the surface will eventually break off to form what is known as wear debris of both the aluminum and the asperities.

The erosive wear

Assuming you carelessly left your engine oil drained from your vehicle in service outside, and your little kid of three was playing somewhere close but unfortunately for you, he poured sand inside this oil. Unknowingly after completion of the vehicle service, you poured this oil containing sand inside your car engine.

What do you think will happen?

Would the car function normally? Yes, it would but would be damaged gradually by the sand in this fluid because as it comes on the surface of the bearing and connecting rod it will scratch the surface gradually giving room for wear to happen. This bearing would eventually reduce in thickness and you would have more clearance than there should.

Of course, you didn’t know there were contaminants in the oil but this Is exactly how erosive wear works by coming in contact through a fluid to the surface of moving surface to cause wear debris.

The corrosive wear

I mentioned something about corrosion and wear earlier. As the unintentional reaction between a material usually metal and the environment. This chemical reaction leads to what is known as rust on the surface of the material and as the material is being slid over another material just like what happened in the abrasive wear. The metal surface comes off leading to wear debris, in corrosion something called pitting might have occurred also leading to total failure of such material.

The fatigue wear

Let us assume you have an anvil, I suppose we all know what that is (where a malleable metal is being beaten into shape) and a hammer with a metal in between. And you carefully place this metal in between the surface of the anvil and hammer and you keep beating the metal.

One thing is sure to happen, the metal spreads out as it is being hit but do you actually think that metal would weigh the same thing as that before being beaten into shape?

Of course not, engineering as found out that some little part of the metal is lost as wear during the process of reshaping and this simple example tells us that under repeated load or cyclic load this is where fatigue wear occurs.

The adhesive wear

macroscopic view of adhesive wear on a surface: image from wikimedia under CCO license

The adhesive wear is one of the types of wear which occurs between two surfaces in which their asperities are in bond with each other (i.e they perfectly sit in each other just like a mechanical gear does) when they do. The movement of these surfaces over each other leads to the breakage of the asperities on both surfaces thereby leading to wear debris.

My summary

When you hear the word wear in whatever context we use it. You should always remember there is a certain field in engineering that discusses wear called tribology. the aspect of wear go hand in hand with friction or let me just say openly that wear is caused by friction and they sometimes even though one's eyes cannot see the wear debris, it does not mean that wear does not occur as it is a gradual process and would indeed be a big problem to have it occurring so fast.

Also, have it in mind that wear cannot be stopped but can be reduced just as friction also cannot be stopped. Wear can come in various forms from fluids to chemical to physical causes. Wear is unwanted and can only be improved by the use of wear resistant materials (i.e. alloying of metals) that have proven stubborn against both the environment and to wear itself.

Thank you for reading!

References

here are the books I read for knowledge

Friction, Wear, Lubrication. A textbook in tribology by K.C Ludema

Friction, Wear and Wear protection by Alfons Fischer and Kirsten Bobzin

Tribology series 5; Surface Effects in Adhesion, Friction, Wear, and Lubrication by Donald H. Buckley

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Wear seems to be a simple topic to discuss about based on fundamental knowledge of an engineering student in his sophomore year. But you've opened my eyes to see and understand more about wear. Initially, i'd say i never knew fluids and corrosion can cause wear but now with your explanation i understand better.

Thanks for being here.

You're welcome bro

Detailed explanation of trilogy.... Wear, friction and tear all can be stopped with the right fluid but where I got confuse is the part of

Please explain

Tribology was removed from my school syllabus when I was in school I don't know why... It's really a nice topic

Wear cannot be stopped it can only be reduced.. Don't get your self confused.

contaminated fluids or the wrong fluids can cause wear or corrosion as the case may be which leads to asperities on the surface of a material.. Leading to wear.

I hope you understand better now?

Thanks @shyllon for the quick reply.. It shows you deeply understood the message i was trying to pass across..

Did u get it or a better explanation from me?

Thanks for the explanation

Wear is just a hired killer to machine parts..If not controlled early on, it could cost the owners a fortune

I love how you broke it down in stages...You're definitely knowledgeable in this field..

Keep writing!

yea... I am glad you found it interesting and you are correct. Thanks for stopping by.

Always a pleasure

Interesting read as usual. I have heard about wear but not so familiar with all the types you wonderfully explained above

Well done

Thank you ibk Gabriel.. i appreciate you here.

Haha! I can remember, rubbing a blunt pencil on a brick wall. We always have a way of developing an alternative ideas (Nija).