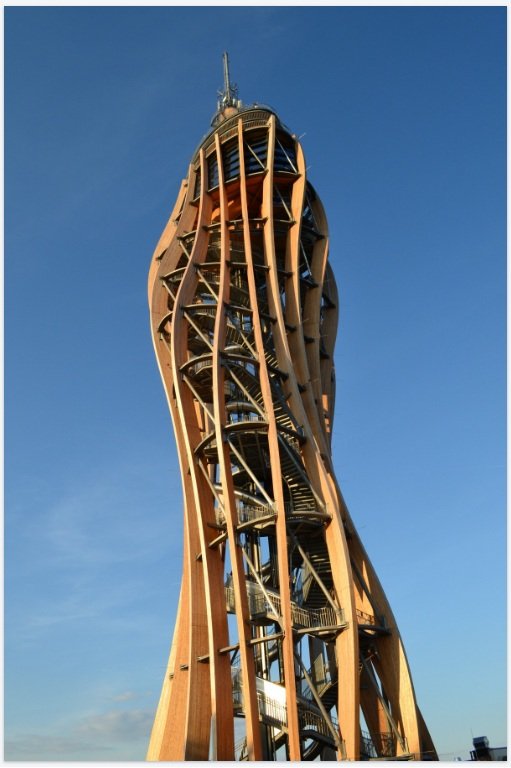

Image Source: Wikimedia Commons(licensed under the Creative Commons Attribution 2.0 Generic license.)

Wood has proven itself to be extremely useful as a building material for construction purpose. Construction of ships and boats, and that of houses bear witness to the priceless usefulness of wood for construction purpose, particularly when treated properly with various chemicals to make it durable and resisting to a variety of attacks, including environmental and biological attacks.

However, woods are of various types. Thus, for construction consideration, it is quite important to opt for those that are quite strong, durable and would resist decay for a longer period of time. It would seem quite unthinking to assume that wood could replace concrete and become, primarily, the building material whose feature would be the basis upon which all other construction material are chosen.

Concrete, no doubt – as I have also discussed in majority of my previous write-ups - is presently the most important construction material and, as a result, many of the building codes (regulations surrounding the ways and manners of conducting construction processes) are developed based on the consideration of concrete characteristics.

Wood has proven to be a good structural material due to some of its mechanical properties. However, it has always never been left to the test of time on its own.In other words, for it to truly serve as a very good structural element, it would have to undergo some treatments. Even after these treatments, it is never expected to last as much as steel or concrete element would when occupying the same position in a structure or when performing the same function in a structure.

Though it is quite tempting to begin analyzing various treatments undergone by wood before it can meet up to structural standards but I shall save that for my next post. However, our major concern here is the Superwood.

Well…

What Exactly Is A Super Wood?

A Superwood is such wood that has been chemically and mechanically treatment to a state that leaves it densified to an extent that it becomes as strong and stiff as steel and even some cutting-edge titanium alloys.

Well, I do not assume the above statements to be as straight forward as I have intended. As a result, I shall try to simplify them as best as I can.

According to one the lead researchers at the University of Maryland,Liangbing Hu, Superwood results from one of their efforts to enhance the mechanical performance of natural woods for building and furniture construction process. In a paper published by the researchers, it was disclosed that the existing treatment methods though produced an improved performance in woods for construction purpose but they are often inconsistent and with incomplete densification and can weaken and expand, particularly in humid environments. In a study to eliminate these flaws, they stumbled upon a material that would even compete effectively with steel, titanium allows and even carbon fiber. It is further claimed to be 12 times stronger than natural wood and 10 times tougher.

According to the team co-leader, a professor of mechanical engineering Teng Li, the wood can even stop bullets. It is claimed that the steel is also six times lighter than steel.

“Amazing!” you’d say. Well, wait until I hint you how the wood could even serve as a windscreen.

How is it (SuperWood) produced?

It must noted that though the Superwood is an engineered wood, it is not the first engineered wood ever. Several attempts have been made overtime to produce a better result to best suit the need of the time, either aesthetically or structurally. Plywood, fiberboard, and particleboard are all examples of engineered that have served In various capacities. The primary process of producing them is to compress (densify) piece(s) of wood to produce a stronger and, sometimes, lighter wood. Sometimes adhesives are used to bind them together.

The basic process of producing the superwood is to first remove the lignin content of the wood. Lignin is the complex polymers that give woody plants their structure, strength, and rigidness. The wood is then compressed under a controlled condition.

The resulting material is the Superwood.

However, I will desire to dive into detail for the interest of the STEM communities, particular those coming across this for the first time. It seem right that you know a bit of what I know of the process right here, right now before you begin making enquiries elsewhere, right.

The Process…

Two basic processes, I mentioned. Lignin removal and densification of the resulting wood.

1. Lignin Removal

As I have mentioned earlier, Lignin is the complex polymers that give woody plants their structure, strength, and rigidness. It is that component that forms the bark cells and provides the strength that makes woody trees to stand firm else they’ll flop over.

It is removed by first soaking the woods in a boiling solution of Sodium Hydroxide (NaOH ) and Sodium Tri-Oxo Sulphate (Na2SO3) in other to dissolve part of the lignin content. The wood is then transmitted to a solution of Hydrogen peroxide (H2O2) to get rid of the remaining lignin content. Lignin is coloured thus its removal subsequently lightens the wood.

Professor Orlando J. Rojas from the Finnish Aalto University indicates that too little or too much removal [of lignin] lowers the strength compared to a maximum value achieved at intermediate or partial lignin removal.

The whole process is similar to that of paper making. The resulting wood would be largely made up of cellulose, a colorless substance in the cell walls that is useful for making paper, plastic and even fabrics and fibres.

2. Densification

Now, at this stage, the wood could either be further processed to produced a clear transparent composite by infiltrating the microstructures of the wood with a polymer (a mixture of #300 resin and #21 nonblushing cycloaliphatic hardener) by immersing the wood in the polymer followed by repeated vacuuming and devacuuming processes. After total infiltration of the polymer, the now white wood becomes transparent.

Yea, I told you. Your next car could really be coming with a transparent wood windshield, you know.

Or the Wood could be densified at 150 degrees Fahrenheit, compressing its cellulose so tightly that it reduces its thickness to one-fifth of its size. The densifying process produces an extremely strong hydrogen bond between the fibres of the wood, giving it its super strength at the end of it all.

And, a five-layer, plywoodlike sandwich of densified wood stopped simulated bullets fired into the material, according to the team at the University of Maryland. An experiment was conducted in regard to this and it was discovered that the multilayers of the wood actually have the ability of stopping bullets. Thus, the wood can further serve as an armor.

Significance To The Construction Industry

No doubt, wood is the cheapest building material from time immemorial second to stone. Wooden buildings abound everywhere. The dependence on wood for construction is more because of its environmental friendly feature and also the time it would ordinarily take to finish a wooden structure than that of concrete or steel structures. Wood is a natural resources, it literally grows from the ground, thus no high-energy fossil fuel is needed to have it produced, unlike steel and concrete.

Wood is also highly resistant to high temperature and also to electricity, unlike steel which can expand and contracts and can also conduct electricity to the detriment of the workers while constructing steel structures. It also has a lighter weight than the rest of the available building materials. There is already enough calls around the world for the adoption of wood as the major building material, such as that of the Michael Greene Architecture in the United States.

However, as good as wood seem for construction it still lacks the exact attainable strength of materials such as steel, its durability is quite questionable in some certain conditions; such as places where the building material is to withstand some extreme weight, extreme temperatures, humid environments or places where multiple impacts are expected. And in places where fire safety are considered, wood is a complete bad choice.

To consider the possibility of engineering wood to attain not only a strength which is even stronger than not just metal but some cutting-edge titanium alloys but also making it more densed and also impenetrable is quite exhilarating. Achieving this could totally eliminate the need for steel as a construction material for all engineering processes except for places where conduction is needed – from the production of large machineries to household items.

The use of the superwood would definitely reduce the total cost of construction and would also enable the designers/architects to come up with more improved designs due to the assurance that this new building material will provide. More durable and light building elements would results and, most importantly, the sustainability of this new material in accordance with the environmental friendliness is assured.

Conclusively

In recent times, awareness over the negative environmental impact of cement and concrete have provoked the engineers to begin looking for new methods and materials to employ for construction with little or no impact on the environment.

Construction of buildings with wood is a long tradition is various part of the world. While wood, itself, is an eco-friendly material due to its source and its resulting interaction with the environment. However, wood is unable to almost meet up with the technical demand of most buildings, particularly those with complex and complicated designs. Even though it is understood that various methods are presently being employed to render wood a suitable construction material, yet these methods have proven inadequate and needs prompt improvement.

With the discovery of the Superwood, which is claimed to be stronger and also lighter than steel, the construction industry, and the whole of the engineering field, have begun on the stride to greater accomplishment, and most importantly, to achieving a feat of recording very low contribution to the current environmental menace the industrial world is presently bestowing upon the universe.

Nature - Processing bulk natural wood into a high-performance structural material

Fast Company - Superwood just as strong as steel

Maximum Yield - What is Lignin?

Wiley - Highly Anisotropic, Highly Transparent Wood Composites

Scientific American - Stronger than steel

Understand Construction - Wood as a construction material

Popular Mechanics - New Chemical Treatment Makes 'Super Wood' That Could Replace Steel

Swedish Wood - Wood as a sustainable construction material

Swedish Wood - Michael Greene, a challenger in the USA

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

I see only two big drawbacks to using this substance. Production methods for superwood would be potentially environmentally destructive as well as complex to perform.

Thank you very much, @quiz1812, for stopping by, and particularly for the comment.

Perhaps you are induced to think this way as regard the material due to its numerous potentials for a large range of use. However, I hope it would interest you to know that the process of producing the superwood is not only simple (i.e can be done even by yourself) but also eco-friendly.

The chemicals indulge in the production process are same indulge while producing papers, while same compression process is employed for the production of engineered woods such as particle boars, plywoods, etc.

Superwood's production is neither complex not potentially destructive to the environment, @quiz1812.

What woods work best for turning into superwood? Can fast growing "soft" woods be used in place of slower growing "hard" woods?

This post has been voted on by the steemstem curation team and voting trail.

There is more to SteemSTEM than just writing posts, check here for some more tips on being a community member. You can also join our discord here to get to know the rest of the community!

This is interesting, though it could lead to further deforestation than necessary but the potential of superwood in the construction industry is something to look forward to