There is a thing I've noticed about smart people, and even though I may never have met you, I always assume every new person I come in contact with is smart. So my consequent assumption is that as a smart person, you also exhibit that same character I've noticed in other smart ones like you and I : You don't like it when someone you are meeting for the first time tells you they are sure about some things in your life. As soon as they say that thing they're sure of, you either instantly tell them how they are outrightly wrong, or in other more delicate cases, you start searching for scenarios where their statement doesn't hold.

I'm guessing that is what you're presently doing, well, I'm no prophet though, I'm just a man fascinated with engines and machines that I have spent my entire adult life trying to understand how both of those things work and how they're designed. However I'm about to tell you something you've done today, and I wouldn't need your validation, for I'm sure I can't be wrong. So here we go : You have directly benefitted from the services of a shaft today.

Don't bother to invalidate it, because whether you have a fan or air conditioner in your room for cooling, or you are reading this from your laptop (which of course has a hard drive), or you have commuted by car, bus, bike or train today to the highly likely possibility that you have used an analog watch today, you couldn't have done any of those without the help of a shaft.

Yes, shafts are everywhere because they come in different sizes and forms that their application pervades all aspects of our everyday living. However, before we go on, there are other meanings of the word shaft, even in engineering, but the shaft I've been and will be referring to here today will be the mechanical shaft.

You will probably agree with me (because I'm done with my predictions) that we owe a lot to these shafts, but then as they are non-living, they may never be able to demand from us humans anything in return for their wonderful services. Well, that wouldn't be a problem, just see me as an advocate for shafts, and all my client is asking is that you show appreciation. After all, that won't be too much of my client to ask, would it?

Yes, quite literally, appreciate shafts. Appreciate as a word has more than one meaning and connotation in English Language, here is one :

"Appreciate often connotes sufficient understanding to enjoy or admire a thing's excellence"

___Merriam Webster Dictionary.

This connotation described above is exactly what my client is asking, and since I also happen to be one of the users of shafts, I will be paying my own debt with an effort to explain the shafts in important details, I hope you will join me, so that we can one and all pay my client what he deserves.

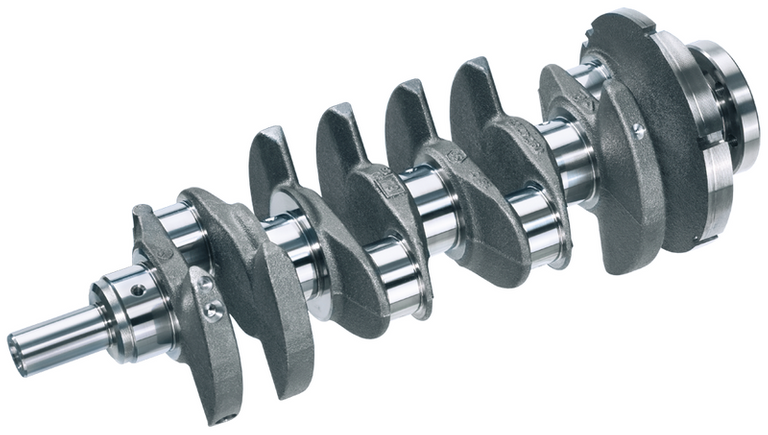

This is important because many who make use of shafts don't even know they do, for some people always expect a shaft to be long and big. In fact, some who are familiar with shafts only think of it as restricted to only the type of shaft they regularly use. Say for example, you ask an auto-mechanic to mention the types of shaft around him, he'll be quick to mention the crankshaft and camshaft, but may not remember to mention the spindle in the watch he dropped in the changing room.

Well then, to avoid any further semblance of such, let's get familiar with shafts.

As mentioned earlier, we are talking about the mechanical shaft, which was defined by Wikipedia as a machine part which rotates for the purpose of transmitting power from a machine component to another, or for the purpose of transmitting power from a power-producing machine to a power-absorbing machine.

These shafts are mounted on bearings and carry out this power transmission work with the aid of pulleys, sprockets and gears mounted on them. They are generally produced by the hot rolling process, then, turning, grinding or cold drawing may be applied to achieve a desired size.

They are usually cylindrical, although they can also be square-shaped or cross-shaped.

As mentioned earlier, there a lot of shafts in different applications, however the broken into two major groups using these yardsticks :

- Their structure

- Their function

When they are classified based on their structure, we have :

Hollow Shafts : As suggested by its name, it is the kind of shaft that has a hole through it. It is usually preferred when the focus of design is on torsional stiffness.

I hope you're not thinking for a moment that its being hollow compromises its strength. If you happened to take classes in Material Science, you might have heard that the main fibres that contribute to stiffness in materials are the outer fibres, the more central the fibres are, the lesser they contribute. Therefore a hollow shaft will offer more strength per weight of material than its solid counterpart. So, engineers sometimes choose to let go of the additional weight of the central fibres, thus choosing strength.

A HOLLOW PROPELLER SHAFT from Wikimedia under CCO licenseSolid Shafts : A solid shaft is the opposite of a hollow shaft, as it has no hole through it. However, do not think because of the explanation given above about the hollow shaft, that the solid shaft is not needed, you'll be wrong. You may want to think of them as a bowl and a basket, both are useful, depending on the task you want to do in your kitchen.

In the same way, depending on what the engineer is focusing his design on and the job the shaft will be doing, he may go for a solid shaft too. For example, if the shaft will also be experiencing bending load, the designer may go for the solid shaft as it is more resistant to bending load than its hollow friend.Stepped Shafts : These are shafts with different diameters in that they taper towards their end in various steps.

Also, when they are classified on the basis of the job they perform, we have :

Transmission Shafts : These are the shafts that transmit power from a power source to the machine absorbing the power. Let's get familiar with three of them :

- Line shafts : They were majorly in use before the availability of electric motors, such that one major power source drives all the needed machines in a factory.

The line shaft will be connected to the major power source and held by bearings either horizontally overhead or vertically. Then pulleys or sprockets are attached at different points to convey the power to different machines.

However, since the electric motors made it possible for every machine to have its own power source, they replaced line shafting. Just so you know, electric motors also make use of shafts.

Shafts that carry pulleys, sprockets and gears are subjected to both bending and twisting.

- Main shafts : These are generally the types of shaft that receive power from the main power source. In some cases they transfer power to the counter shaft.

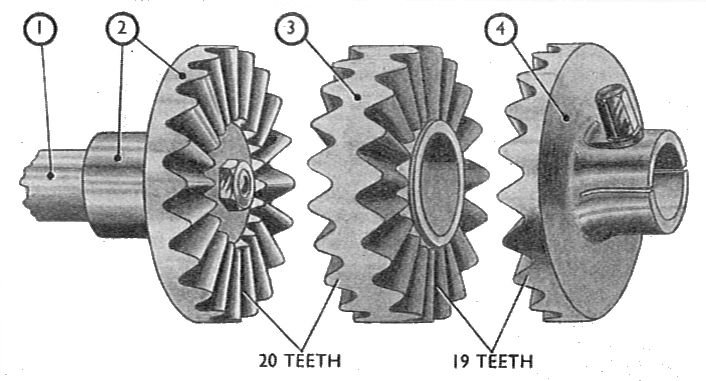

- Counter shafts : You can call this an intermediary between shafts as it transfers or you could say synchronize power between a driving shaft and the driven shaft. In cases where gears are used, the counter shaft may have to employ bevel gears to transmit the power. They are the types of shafts used in gear boxes of vehicles and machines.

- Line shafts : They were majorly in use before the availability of electric motors, such that one major power source drives all the needed machines in a factory.

Machine shafts : These are the types of shafts found in a machine that form an integral part of the machine itself. You may have a heard of a particular type of this before, however, I'll explain that and one other type that you may not have been paying attention to :

A CRANKSHAFT from Wikimedia under CCO license- Crankshafts : These are types of shafts that are used to convert between reciprocating motion and rotating motion for the purpose of transmitting power.

You may quickly remember its use in the Internal combustion engines where it converts reciprocating motion from the piston to rotating motion. However, in reciprocating compressors, it converts rotating motion to reciprocating motion.

It does this conversion job by having shafts held by crankpins whose axis are offset from the main axis of the crankshaft.

- Spindles : These are small short shafts that also rotate. They are usually employed to transfer motion. You will find them in drilling machines or on lathes. And just in case you've been wondering which type of shaft is in your watch, here you have it.

- Crankshafts : These are types of shafts that are used to convert between reciprocating motion and rotating motion for the purpose of transmitting power.

At this point, there are two worthy mentions of two of my client's best relatives (in case you forgot, I'm the shaft's advocate), shafts owe as much to these components as we owe the shaft. They help the shafts to easily carry out their job of transmitting power. They are highlighted below :

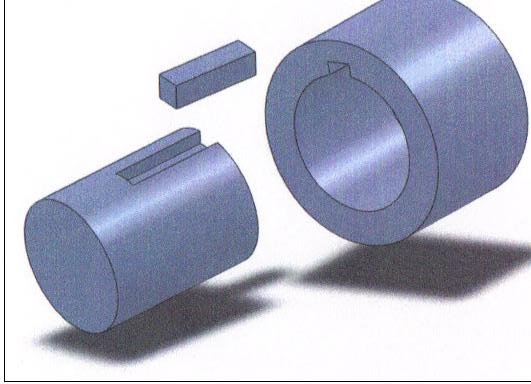

- KEYS : This is a small piece of mild steel inserted between a pulley and a shaft to prevent any relative motion between both elements. It fits into a keyway which is a slot made on both components it is to connect. They experience shearing and crushing stresses. Types of keys include Sunk keys, Saddle keys, Tangent keys, Round keys and Splines.

- COUPLINGS : Sometimes a shaft may be needed to transmit power over a long distance, however, standard shaft sizes are limited to 7 meters, so whenever power transmission is needed beyond this length, couplings come to the rescue. They join two or more shafts to each other. They also serve other purposes which include :

- They connect shafts of separately manufactured units like generators and motors.

- They provide mechanical flexibility by allowing for misalignment of shafts.

- They also dampen the effects of shock loads transmitted from one shaft to the other.

- They also protect against overload.

The different types of shaft couplings available are divided into these two major groups :

- Rigid couplings : These are used to connect shafts which are in alignment. Some types are Sleeve or muff coupling, Clamp or split-muff coupling and Flange coupling.

- Flexible couplings : They are used for connecting shafts which are angularly and laterally misaligned. Some types are Bushed pin coupling, Universal coupling and Oldham coupling.

If you want to appreciate shafts the more, you may like to know that for them to carry out their job successfully and ensure you don't get angry when that fan breaks down or the crankshaft of the engine is damaged, they have to resist deformation. This resistance to deformation is technically referred to as stress.

Due to the type of job they do, the kind of forces that tend to cause the their deformation are forces that tend to twist them, forces that tend to bend them due to the elements they carry like pulley or gear, and at times they have to resist deformation from a combination of both forces at the same time.

An engineer will expect me to write that paragraph above as The types of stresses shafts experience include Shear stress due to transmission of torque(torsional load), Bending stress due to the forces affecting the machine elements carried by the shaft, and finally Stresses due to the combined action of torsional and bending forces.

Well, don't sweat it, we are still saying the same thing, and my client doesn't expect you to bore yourself with too much technical details, since it is not your profession, you are only required to appreciate the shaft.

However, my client has asked me to tell you that they are in the position to help you because engineers carefully selected them after serious calculations and considerations in a process they proudly call designing.

When an engineer begins to design for a shaft, he either designs it based on strength, in which case he will be considering the different force scenarios just mentioned and select a shaft that will be able to offer more resistance than is exactly needed. This additional resistance is required for safety in the event the shaft is loaded beyond its design load.

Factor of safety is an important aspect of engineering design, where the design is expected to make provisions for an assumed overuse of the designed element by the user, also it provides for reduction in original strength of machine parts that may have substantially reduced over time either due to wear and tear or realities of working condition.

Also an engineer may decide to design a shaft based on how rigid he expects the shaft to be either against a twisting load or how much the shaft is allowed to deflect laterally. In this case, he is said to be designed based on rigidity or stiffness.

.jpg)

A COUPLING from Wikimedia under CCO license

I'm glad that we've reached this destination together, at least now we have come to know important things about the shaft and some places we may not easily have noticed their existence. I'm sure my client will be so happy too, that is of course if he were a living element.

Truly, shafts may not breathe in oxygen, but they breathe life into our everyday endeavors, so much that we almost wouldn't be able to do anything at all. Just imagine, almost all means of transportation if not all, directly make use of shafts. Yes, your car makes use of at least 3 types of shaft (crank shaft, cam shaft, propeller shaft).

Remember without power generation, our activities on earth are crippled, but save for solar power which I don't know too much about, all other forms of power generation, from the turbines in hydroelectric power plants to gas turbines in gas based generating plants, to the wind mills for generating power, you have something as fundamental to life as power because shafts do their job well.

Thank you for honoring my client's wish, I hope you continue to notice and appreciate the precious jobs shafts do for us in whatever form or size they are made.

Just in case you have became inspired and want to know much more about shafts, keys and couplings, you will find helpful information in the references provided below.

REFERENCES

- Khurmi R S, (2014), 'A text book of machine design', Eurasia publishing house(P) ltd., New-Delhi, ISBN 9788121925372

SHAFTS | TYPES AND DESIGN OF SHAFT KEYS | CRANK SHAFT | LINE SHAFTS.

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Dear friend! Next time also use #wafrica and follow @wafrica to get an upvote on your quality posts!

Disorienting and reorienting me to a devastating effect. I'm still clapping for you.

Thanks, I'm glad you enjoyed reading, these kind of comments encourage me to do better.

To think about the time you expended on this piece, is enough to make me appreciate. Well done.

First It was cylinders and engine strokes then pistons now shaft, does it mean you want to dissect the automobile engine for our understanding

Thank you for reading and for the encouragement. Like I said at the beginning of this post and others, I love engines, so yes, eventually you will get to hear a lot from me about engine parts, but I can't tell you how soon. However, I haven't thoroughly told you about the crankshaft and camshaft yet, if you are still around, I'll surely swing them your way.

This post, though was manly borne out of the fact that I've seen many people who make use of shafts very frequently without being aware of it, so I felt I should share what I know.

Congratulations @sogless, this post is the tenth most rewarded post (based on pending payouts) in the last 12 hours written by a Newbie account holder (accounts that hold between 0.01 and 0.1 Mega Vests). The total number of posts by newbie account holders during this period was 3701 and the total pending payments to posts in this category was $2122.40. To see the full list of highest paid posts across all accounts categories, click here.

If you do not wish to receive these messages in future, please reply stop to this comment.

Interesting stuff. Reading your blog within a year should be enough for me to open a mechanic workshop :)

I'm glad you're reading them all, my fascination with engines is deep-reaching, and if I turn a Life-scientist into an auto-mechanic, that will be a great achievement.

One way or the other i have so much benefited from shafts either through transportation or movement. I remember it was the answer to my siwes defense.. We made a truck.

Thank you for stopping by as usual, and for caring enough to drop a comment.

You are welcome.. Keep the fire blazing.

Congratulations @sogless! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPI remember someone telling me shaft was the whitish stuff from the maize fruit. 😂😂😂

I don't know how much you laughed when you heard this, but I've been laughing since i saw this. Thanks for reading through.

Being A SteemStem Member