Today I want to show you a part of my working day, the realization of the corrective maintenance of the oil filter of an HYSTER forklift with a capacity of 1000kg

Corrective maintenance is understood as all that set of tasks aimed at correcting the defects that are presented in the different equipment and that are communicated to the maintenance department by the users of the same.

Well, the forklift driver notified the maintenance department that the unit had failures when lifting a heavy object, the decision was made to maintain the oil filter because that could be the possible cause of this failure.

Tools to use, screwdriver and deep Socket Set.

A special silicone was also used for this repair.

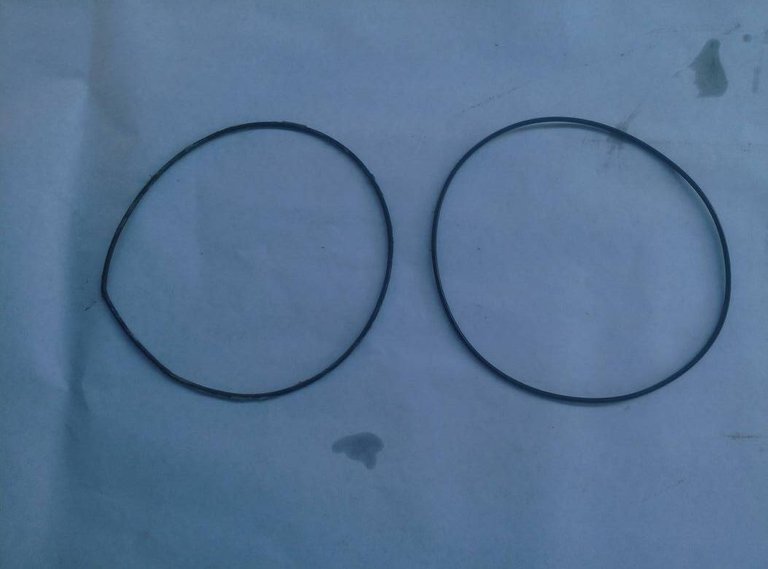

The only thing that needed to be replaced was the Orrin since the one that was placed was in poor condition.

The oil filter of the forklift was disassembled, to be repaired.

Uncovering the oil filter to know its internal conditions.

We realized that it had many impurities, it was washed with a special diluent and then it was preceded to blow with compressed air to be faster the cleaning and drying process.

After the cleaning process was finished, the new Orrin was replaced since the one that was placed was in very poor condition. Silicon was applied to seal the filter cover and thus prevent the oil that is stored in the crankcase from becoming contaminated.

A layer of silicone was applied to the gasket that joins the Carter with the oil filter to improve its sealing.

Conclusion:

After the maintenance of the oil filter was carried out, we continued with the oil change since the oil was already oxidized and that would cause us to malfunction the vehicle again.

The forklift was fully operational, this maintenance was carried out in time of about 3 hours and in the hands of a maintenance worker.

References:

• Manufacturer's manual, Hyster Forklift.

Steem needs more how to article like this. Not that I have a fork lift to use this on, but it is interesting learning odd ball things.