Bacterial cellulose is an organic compound with the formula (C6H10O5)n produced by certain types of bacteria. While cellulose is a basic structural material of most plants, it is also produced by bacteria, principally of the genera Acetobacter, Sarcina ventriculi and Agrobacterium. Bacterial, or microbial, cellulose has different properties from plant cellulose and is characterized by high purity, strength, moldability and increased water holding ability.

In natural habitats, the majority of bacteria synthesize extracellular polysaccharides, such as cellulose, which form protective envelopes around the cells. While bacterial cellulose is produced in nature, many methods are currently being investigated to enhance cellulose growth from cultures in laboratories as a large-scale process. By controlling synthesis methods, the resulting microbial cellulose can be tailored to have specific desirable properties. For example, attention has been given to the bacteria Acetobacter xylinum due to its cellulose’s unique mechanical properties and applications to biotechnology, microbiology, and materials science. Historically, bacterial cellulose has been limited to the manufacture of Nata de coco, a South-East Asian food product. With advances in the ability to synthesize and characterize bacterial cellulose, the material is being used for a wide variety of commercial applications including textiles, cosmetics, and food products, as well as medical applications. Many patents have been issued in microbial cellulose applications and several active areas of research are attempting to better characterize microbial cellulose and utilize it in new areas.

credit

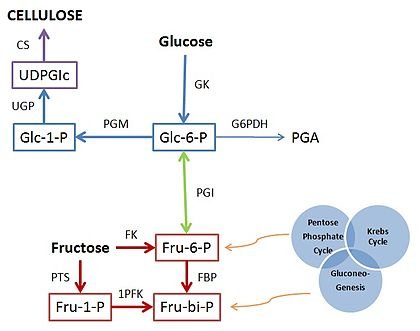

Biochemical Pathway for Cellulose Synthesis

Cellulose is the earth’s major biopolymer and is of tremendous economic importance globally.

Cellulose is the major constituent of cotton (over 94%) and wood (over 50%). Together, cotton and wood are the major resources for all cellulose products such as paper, textiles, construction materials, and cardboard, in addition to cellulose derivatives such as cellophane, rayon, and cellulose acetate.

Cellulose from major land and forest plants and cotton is assembled from glucose, which is produced in the living plant cell from photosynthesis.

In the oceans, however, most cellulose is produced by unicellular plankton or algae using the same type of carbondioxide fixation found in photosynthesis of land plants. In fact, it is believed that these organisms, the first in the vast food chain, represent nature’s largest resource for cellulose production. Without photosynthetic microbes, all animal life in the oceans would cease to exist. Several animals, fungi, and bacteria can assemble cellulose. However, these organisms are devoid of photosynthetic capacity and usually require glucose or some organic substrate synthesized by a photosynthetic organism to assemble their cellulose.

Cellulose is the most abundant, inexpensive and readily available carbohydrate polymer in the world, traditionally extracted from plants or their wastes. This polymer normally branches with hemicellulose and lignin has to undergo unhealthy chemical process with harsh alkali and acid treatment to obtain the pure product. Increasing demand on derivatives of plant cellulose had increased wood consumption as raw material, causing deforestation and global environmental issue.

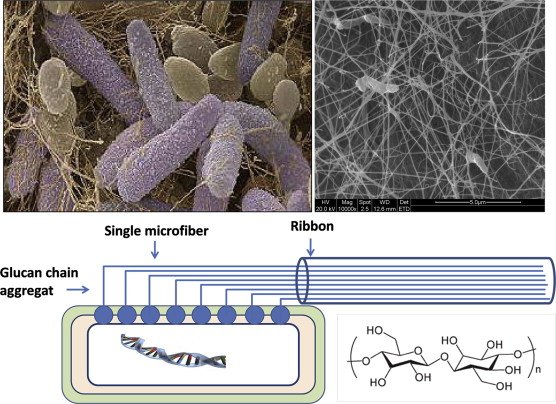

Although plant is the major contributor of cellulose, various bacteria are able to produce cellulose as an alternative source. Bacterial cellulose (BC) was initially reported by Brown (1988) who identified the growth of unbranched pellicle with chemically equivalent structure as plant cellulose. Due to BC structure that consist only glucose monomer, it exhibits numerous great properties such as unique nanostructure, high water holding capacity, high degree of polymerization, high mechanical strength and high crystallinity.

The discovery from previous researches had clearly shown that BC and its derivatives have tremendous potential and provide a promising future in various fieldssuch as biomedical, electronic and food industrial.

credit

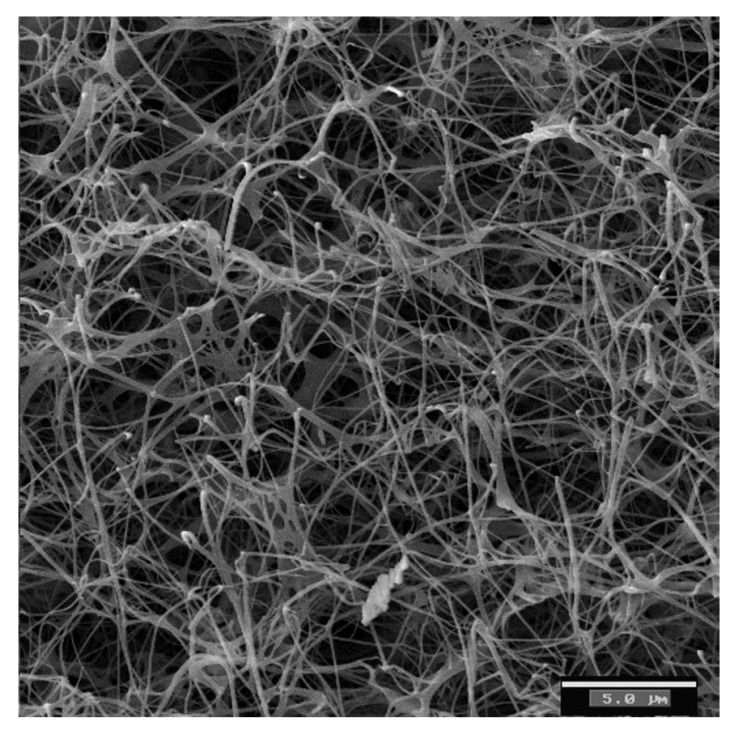

SEM micrograph of a bacterial cellulose sample showing a coherent 3-D network formed by cellulose fibers

connected by physical joints

BC is produced by acetic acid bacteria in both synthetic and non-synthetic medium through oxidative fermentation. Acetobacter xylinum is the most studied and the most efficient BC producer that manage to assimilate various sugars and yields high level of cellulose in liquid medium. This aerobic gram-negative bacteria actively fermented at pH 3-7 and temperature between 25 and 30˚C using saccharides as carbon source reported that almost 30% of bacterial fermentation is belong to the cost of fermentation medium. High cost and low-yield production has limited the industrial production of BC and its commercial application. Therefore, it is important to look for a new cost-effective carbon source with shorter fermentation process for high yield BC production.

HISTORY

As a material, cellulose was first discovered in 1838 by Anselme Payen. Payen was able to isolate the cellulose from the other plant matter and chemically characterize it. In one of its first and most common industrial applications, cellulose from wood pulp was used to manufacture paper. It is ideal for displaying information in print form due to its high reflectivity, high contrast, low cost and flexibility. The discovery of cellulose produced by bacteria, specifically from the Acetobacter xylinum, was accredited to A.J. Brown in 1886 with the synthesis of an extracellular gelatinous mat. However, it was not until the 20th century that more intensive studies on bacterial cellulose were conducted. Several decades after the initial discovery of microbial cellulose, C.A. Browne studied the cellulose material obtained by fermentation of Louisiana sugar cane juice and affirmed the results by A.J. Brown. Other researchers reported the formation of cellulose by other various organisms such as the Acetobacter pasteurianum, Acetobacter rancens, Sarcina ventriculi, and Bacterium xylinoides. In 1931, Tarr and Hibbert published the first detailed study of the formation of bacterial cellulose by conducting a series of experiments to grow A. xylinum on culture mediums.

In the mid-1900s, Hestrin et al. proved the necessity of glucose and oxygen in the synthesis of bacterial cellulose. Soon after, Colvin detected cellulose synthesis in samples containing cell-free extract of A. xylinum, glucose and ATP. In 1949, the microfibrillar structure of bacterial cellulose was characterized by Muhlethaler. Further bacterial cellulose studies have led to new uses and applications for the material.

APPLICATIONS

Bacterial cellulose has a wide variety of current and potential future applications. Due to its many unique properties, it has been used in the food industry, the medical field, commercial and industrial products, and other technical areas. Bacterial cellulose is a versatile structural material, allowing it to be shaped in a variety of ways to accommodate different uses. A number of patents have been issued for processes involving this material.

FOOD

The oldest known use of bacterial cellulose is as the raw material of nata de coco, a traditional sweet candy dessert of the Philippines. It has also been used as a thickener to maintain the viscosity in food and as a stabilizing agent. Due to its texture and fiber content, it has been added to many food products as a dietary fiber. A specific example is Cellulon ®, which is a bulking agent used as a food ingredient to act as a thickener, texturizer, and/or calorie reducer. Microbial cellulose has also been used as an additive in diet beverages in Japan since 1992, specifically kombucha, a fermented tea drink.

credit

SEM images of Acetobacter xylinus, formation of Bacterial cellulose, and BC in food applications.

COMMERCIAL PRODUCT

Bacterial cellulose also has wide applications in commercial industries. In papermaking, it is used as an ultra-strength paper and as a reticulated fine fibre network with coating, binding, thickening and suspending characteristics. Due to its high sonic velocity and low dynamic loss, bacterial cellulose has been used as an acoustic or filter membrane in hi-fidelity loudspeakers and headphones as marketed by the Sony Corporation. Bacterial cellulose is also used as an additive in the cosmetic industry. Furthermore, it is being tested in the textile industry, with the possibility of manufacturing cellulose based clothing.

credit

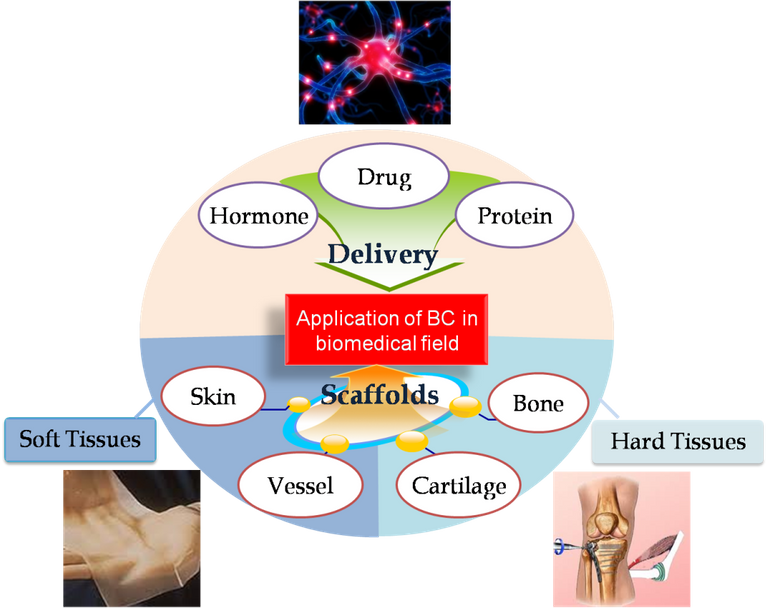

Bacterial Cellulose for Skin Repair Materials

MEDICAL

In more modern applications, microbial cellulose has become relevant in the medical sector. It has been tested and successfully used as a wound dressing, especially in burn cases. Studies have shown that burns treated with microbial cellulose coverings healed faster than traditional treatments and had less scaring. The microbial cellulose topical applications are effective due to the cellulose's water holding ability and water vapor permeability. The high water holding ability provides a moist atmosphere at the injury site, which is critical in healing, while the wicking ability allows seepage from the wound to be removed from the site. Also, the microbial cellulose molds very well to the surface of the skin, providing a conformal covering even in usually difficult places to dress wounds, such as areas on the face. This technique has been so successful that commercial microbial cellulose products, such as Biofill ®, have been developed. Another microbial cellulose commercial treatment product is XCell produced by the Xylos Corporation, which is mainly used to treat wounds from venous ulcers. Studies have also been performed where traditional gauze dressings are treated with a microbial cellulose biopolymer to enhance the properties of the gauze. In addition to increasing the drying time and water holding abilities, liquid medicines were able to be absorbed by the microbial cellulose coated gauze, allowing them to work at the injury site.

Microbial cellulose has also been used for internal treatments, such as bone grafts and other tissue engineering and regeneration. A key ability of microbial cellulose for medical applications is that it can easily be molded into various shapes while still retaining all of its useful properties. By molding microbial cellulose into long, hollow tubes, they can be used as replacement structures for several different areas, such as the cardiovascular system, the digestive tract, urinary tract, or the trachea. A recent application of microbial cellulose has been as synthetic blood vessels and stents. The cellulose can also be modeled into mesh membranes that can be used for internal replacement structures, such as the brain's outer membrane, the dura mater. In addition to replacement, these structures have also been used as grafts to interact with existing internal biological material. Microbial cellulose has also been used in guided tissue regeneration. Bioprocess ® and Gengiflex ® are some of the common trademarked products of microbial cellulose that now have wide applications in surgery and dental implants. One example involves the recovery of periodontal tissues by separating oral epithelial cells and gingival connective tissues from the treated root surface.

References

1 2 3 4 5 6 7 8 9 10

Thanks for visiting my page.

Leave a comment below if you find the topic helpful. Don't forget to Upvote and Follow @jaybaba. Best Regards @jaybaba

thanks for sharing very useful info,,,@jaybaba

very good information,

to research germs is not an easy thing ..

your post is good enough to get it .. thanks friends.

post upvote and MY FOLLOWING