Hello Steemians;

How are you guys doing today?. As for me I'm happy to be back with an interesting topic for you guys.

Most of you guys know one or two things about engines, I wrote a post on Compression Ignition Engines here some weeks ago and now I'm coming down to the basis, which is the classification of engines.

This is a very important and interesting Auto Mechanical Engineering topic, so I implore you guys to take your time to read this article and I promise you're gonna grab something new from this post.

Now to the main business of the day;

As we all know that the engine is the backbone of any machine. Now we have to know how they are being classified.

Engines are classified based on;

The type of fuel: Diesel, Petrol, Gas, Bio/Alternative fuels.

The Cycle Classification (Number of strokes): Two-Stroke cycle engine and the Four-Stroke cycle engine.

The type of ignition: Spark ignition Engine (S.I.E) and the Compression Ignition Engine (C.I.E).

The number of cylinders: From 1 – 18 cylinders.

The arrangement of the cylinders: Inline, V, W, Horizontal and Radial.

The Motion of Pistons: Reciprocatory and Rotary motions.

The Size / Capacity.

The Bore-to-Stroke ratio.

The combustion method: Internal Combustion Engine (I.C.E) and External Combustion Engine (E.C.E).

The engine cooling method: Air cooled, Liquid cooled (Water based), Oil-cooled (Oil is cooled separately).

The Breathing: Naturally Aspirated, Turbocharged/Supercharged’.

But for this particular article, I’m going to dwell into the Cycle Classification which is number 2 on my list.

So sit tight and let’s go on a trip to the engine world.

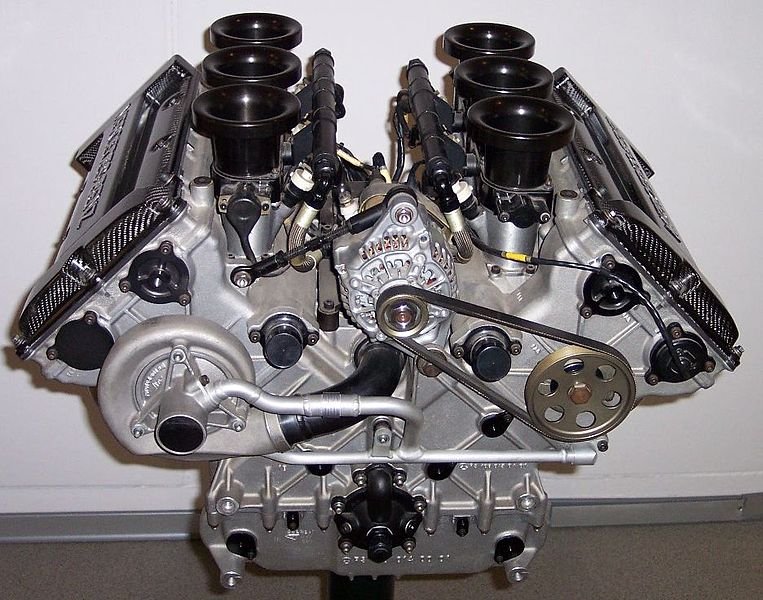

Mercedes V6 DTM Rennmotor 1996 Engine from Wikimedia under GNU Free Documentation License

It is now necessary to describe the sequence of operation by which the combustible charge is introduced, ignited and burnt and finally discharged after it has completed its work.

There are two important ‘cycles’ of operation in practical use, namely;

The “four-stroke” or “otto” cycle as it is sometimes called after the name of the German engineer “Nikolaus Otto” who first applied it in practice

The “two-stroke” or “clerk” cycle, which has owed its development largely to the late Sir Dugald Clerk.

The cycles take their names from the number of single piston strokes which are necessary to complete a single sequence of operation. Cycle is a sequence of operation being repeated continuously so long as the engine works.

However, the vast majority of automobile engines use the four-stroke cycle engine.

_(14785242443).jpg)

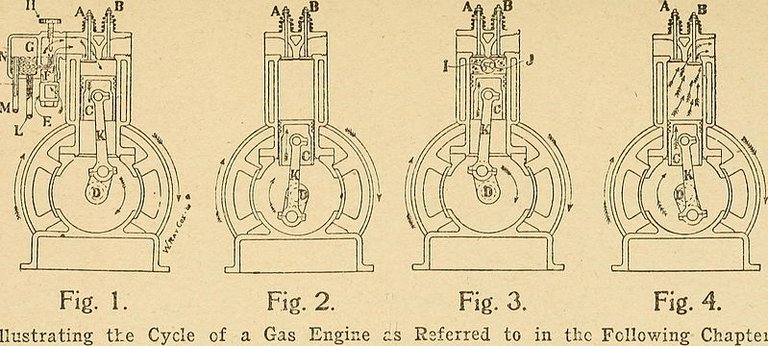

ILLUSTRATION OF A FOUR-STROKE CYCLE from Wikimedia

The Four-Stoke cycle engines are the most basic engines used in most cars and bikes.

The name itself gives us an idea of what we’re dealing with, it is an Internal Combustion Engine (I.C.E) where the piston completes four strokes while turning the crankshaft twice. As mentioned earlier the Four-Stroke cycle engine was first demonstrated by Nikolaus Otto in 1876.

Now let’s discuss the parts that makes up the Four-Stroke cycle engine;

- The Piston.

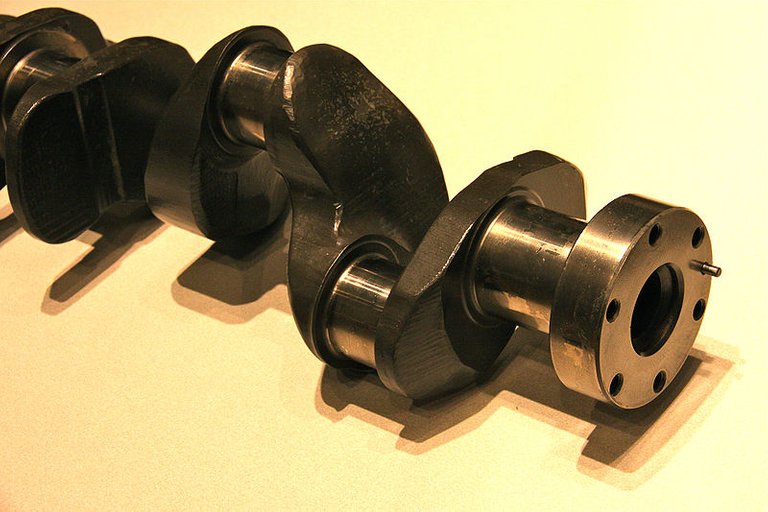

- The Crankshaft.

- The Connecting rod.

- The Flywheel.

- The Inlet and Outlet Valves.

- The Spark Plug.

The Piston:

It is responsible for the transfer of the expanding force of gases to mechanical rotation of crankshaft through the connecting rod.

The Crankshaft:

It is responsible for the conversion of reciprocating motion to rotational motion.

The Connecting rod:

It is responsible for the transfer of motion from a piston to crankshaft which acts as a lever arm.

The Flywheel:

It is a rotating mechanical device for storing energy.

The Inlet and Outlet valves:

They allow intake of fresh air with fuel and exit of the air-fuel mixture spent from the cylinder.

The Spark Plug:

It is responsible for the delivery electric current to the combustion chamber which ignites the air-fuel mixture leading to abrupt expansion of gas.

The four-stroke cycle consists of the four strokes, namely;

- Induction Stroke

- Compression Stroke

- Power Stroke

- Exhaust Stroke

.jpg)

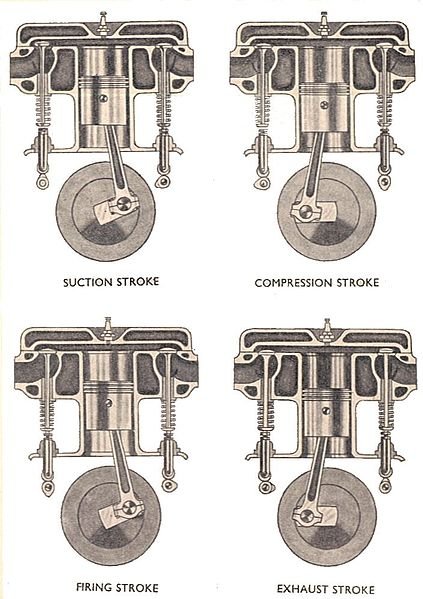

FOUR-STROKE CYCLE from Wikimedia

Induction Stroke:

The momentum of the outgoing exhaust gas creates partially a vacuum within the cylinder even before the piston has moved far on the induction stroke. The atmospheric pressure (atm pressure) being greater compared to the depression in the cylinder will cause a flow of vaporised fuel and air from the Carburettor. The inlet valve remains open until some 50° after B.D.C (Bottom Dead Centre) to take advantage of the momentum of incoming mixture which may have a speed of 30 – 90 meters per sec.

To obtain the maximum filling of the cylinder the inlet valve opens about 10° before T.D.C (Top Dead Centre) while the exhaust valve closes some 10° after T.D.C giving 20° of valve overlap.

Compression Stroke:

On the petrol engine the charge is compressed into about one-eight of its original volume, while the pressure rises to about 1034 kpa (kilopascals) depending upon various factors including the compression ratio, throttle opening and engine speed. The two valves are closed.

Power Stroke:

Near the top of the stroke the mixture is ignited by a spark which bridges the gap at the plug points.

Combustion of the charge results in very high temperatures, which may exceed 2000°C on full throttle. The high temperature produces a rise in pressure of the gas which is followed by a fall in pressure as the piston traverses the power stroke.

Exhaust Stroke:

In this stroke, the exhaust valve opens some 50° before B.D.C (Bottom Dead Centre) allowing the pressure within the cylinder to fall and so reduce ‘back’ pressure on the piston during the exhaust stroke. The valve will open until about 10° after T.D.C (Top Dead Centre).

- It is widely used in automobile industries.

- It is used in pumping system.

- It is applied in mobile electric generators.

- It is widely used in aircraft and marine engines.

- It is applied in construction machinery, air compressor, drilling rigs e.t.c

Advantages:

- It gives higher efficiency.

- It creates less pollution.

- It is quitter in operation.

- It runs cleaner due to the fact that there is no extra oil added in fuel.

Disadvantages:

- These engines are more complicated due to valve mechanism and the lubrication system.

- It gives less power.

- It is expensive compared to the two-stroke cycle engine.

And now we move to the Two-Stroke cycle;

TWO-STROKE CYCLE ENGINE from Wikimedia under CC3.0 License

The two-stroke cycle engine is a type of I.C.E which completes a power cycle with just two strokes (the events above the piston and the event below the piston) during only one crankshaft revolution unlike the four-stroke cycle engine.

The Two-Stroke cycle engines have high power-to-weight ratio compared to the Four-Stroke cycle engines.

The two cycles the Two-Stroke cycle engine goes through are the;

- Events above the piston

- Events below the piston

Below is for three-port, Crankcase compression, single-cylinder engine.

The two-stroke engine has no valve, the sides of the piston being employed to open and close ports in the cylinder walls at the correct intervals.

Events above the Piston

During this period, the piston rises compressing the charge in the combustion chamber. Near T.D.C the compressed gas is ignited by a spark bridging the gap at the point. The high temperature produced by the combustion of the charge causes a rise in pressure, followed by expansion as the piston travels down. Near B.D.C there are two ports in the cylinder wall – the transfer port, communicating with the crankcase, and the exhaust port. As the piston nears B.D.C it uncovers first the exhaust port, releasing the burnt gas and then the transfer port, admitting to the cylinder compressed charged from the crankcase.

Events below the Piston

During this period, each upward stroke of the piston creates a partial vacuum in the crankcase, and near T.D.C, the lower edge of the piston skirt uncovers the inlet port, admitting a fresh charge of gas from the carburettor.

As the piston descends, the inlet port is closed and the charge is compressed in the crankcase until the transfer port is exposed, allowing the gas to escape into the cylinder.

It is to be noted that a deflector head piston is used to direct the incoming gas to the top of the cylinder.

The crankcase must be small and gas tight to provide adequate crankcase compression.

- It is used in small vehicles like mopeds, schooters e.t.c.

- It is used in small gasoline engines which are used for lawn mowers.

- It is used in ship propulsion

- It is used in small electric generator set, pumping set and outboard motor boats.

Advantages:

- Its cost is lower.

- High power compared to the four-stroke engines.

- More power-to-weight ratio.

- Easy to maintain due to absence of valve mechanism and lubrication system.

- Easy to start and simple in mechanism.

Disadvantages:

- More wear and tear due to the poor lubrication system.

- It results to high vibration and noisy operation.

- It is less efficient compared to the four-stroke-cycle.

- It burns lubrication oil with charge and therefore produces more pollution.

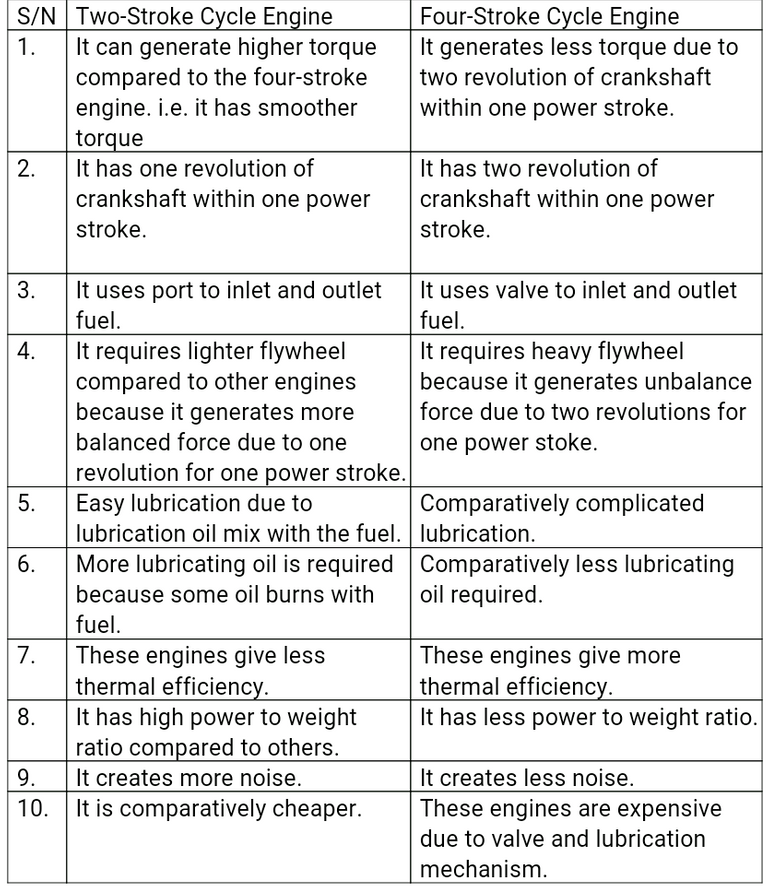

Differences between the Two-Stroke Engine and the Four-Stroke Engine:

Image created by me.

Thanks for your attentiveness. I hope I fulfilled my promise of you grabbing something new from the article.

My Sources;

Auto Technology Fundamentals by Dr K.A Salami

Congratulations @h-max! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPThe four stroke and the two stroke engines have different methods of completing a mechanical cycle..

Nice one!

Excellent post thank you. I love to work on cars as a hobby and it’s interesting the explanation of the different stroke engines. I always thought of boats when comparing two stroke to four stroke engines; I didn’t know that cars were four stroke but it makes sense it’s much more efficient.