Hello STEEMITES!!! Thanks for checking on my blog once again, I believe that we enjoyed the last ride together. Today

I will be discussing something vital that we have been using both at home and our various places of work but seriously we might not know how it works.

Sensor in its simplest term can be defined as a device, module, subsystem, which is capable of detecting events or changes in its environment such as light, moisture, temperature, position, humidity, speed, pressure, blood, sound, heat, etc as input and respond with feedback to other electronics. In most times a computer processor which converts the analogue signals to digital signals (electrical signals) that are readable and comprehensible to human, at the sensor location or transmitted over a network for reading or for more processing. Sensor always works in conjunction with other electronics, whether as simple as a light or a complex as a computer.

Sensors are sophisticated devices that are frequently used to detect and responds to electrical or optical signals. Sensor finds its application across a wide range of industries, including Medical, Industrial, Appliances, Aerospace and Defense, Automotive, Industrial and Commercial Transportation.

Factors or characteristics to be considered before a sensor are to be chosen. They are as listed below:

Resolution:

sensor’s resolution is the smallest change it can detect in the quantity that it is measuring. Sensor’s resolution with a digital output is usually the resolution of the digital output. The resolution is interwoven to the precision with which the measurement is made, but they are not the same thing.

Sensitivity:

The sensitivity is defined as the ratio between the output signal and the input signal (measured property). For instance, if a sensor measures pressure and has an output of current, the sensitivity is a constant with the units [A/K]. The sensitivity is the gradient of the transfer function. To convert the sensor's electrical output to the measured units it requires that we divide the electrical output by the slope.

The sensitivity of a censor indicates how much the sensor's output alters when the input quantity being measured alters. Example given, if the mercury in a thermometer moves 1 cm when there is change in temperature by 1 °C, the sensitivity becomes 1 cm/°C. Some measured quantities can also be affected by some sensors by altering their sensitivity. For example, if a hot liquid is poured into a cup and a thermometer is also inserted hot cup of the liquid, the cup cools the liquid while the liquid heats the thermometer.

Sensors are usually designed to have a small effect on what is measured; making the sensor smaller often improves this and may introduce other advantages. The use of modern day technology has allowed more sensors to be produced on a microscopic scale as microsensors using Micro Electrical-Mechanical (System MEMS) technology. In most cases, microsensor has a better speed and sensitivity compared with macroscpic approaches.

Cost: the amount of money to be spent.

Repeatability:

The reading that varies is repeatedly measured under the same environment

Calibration: Essential for most of the measuring devices as the readings changes with time Environmental condition: usually has limit for wind, temperature and humidity

Range: the total distance that the sensor will cover

Types or classifications of sensor

Types or classifications of sensor depend on:

Primary Input quantity: input quantity depends on the type of sensor to be used.

Transduction principles: Transduction principle is the fundamental criteria which are followed for an efficient approach. Usually, material and technology criteria are chosen by the development engineering group.

Material and Technology Property:

Classification based on property is as given below:

Temperature: integrated circuit (IC), thermistors, thermocouples, resistance temperature detector (RTD’s), and many more.

Pressure: Fibre optic, vacuum, elastic liquid based manometers, LVDT, electronic.

Flow: Electromagnetic, differential pressure, positional displacement, thermal mass, etc.

Level Sensor: Differential pressure, ultrasonic radio frequency, radar, thermal displacement, etc.

Closeness and displacement: this depends on the proximity and the distance of the applied sensor. Such as ultrasonic, photoelectric, Linear Variable Differential Transformer (LVDT), capacitive, magnetic.

Biosensors: Resonant mirror, electrochemical, surface Plasmon resonance, Light addressable potentio-metric. image - Charge coupled devices, complementary metal-oxide semiconductors (CMOS).

Acceleration: Gyroscopes, Accelerometers.

and others like: Speed sensor, moisture, humidity sensor, mass, Tilt sensor, force, viscosity.

Application

The use of sensor’s devices are not too hard to come by with in everyday objects such as touch-sensitive, elevator buttons (tactile sensors) and lamps which dim or brighten by touching the base, moreover sensor applications cut across all sphere of lives of which most people are never aware.

The use of microcontroller platforms has create an easy way for the advancement in technology, the use of sensor has gone beyond the traditional fields of temperature, pressure or flow measurement, for example into MARG sensors. Industrially, sensor cut across all production of; manufacturing and machinery, aerospace, cars, medicine, robotics and the likes. Analog to digital converter is always needed to convert an analog signal to a digital signal before it can be processed or used in digital equipment.

Here are few examples of areas of application of sensors:

Medical: In a mercury-based glass thermometer, the input is temperature. The liquid contained expands and contracts in response, causing the level to be higher or lower on the marked gauge, which is human-readable.

Automotive: the gasoline/oxygen ratio in a car’s emission control system is detected by oxygen sensor, usually through a chemical reaction that generates a voltage. A computer in the engine reads the voltage and, if the mixture is not optimal, readjusts the balance.

Motion sensors: a lot of houses use gadgets contain sensor embedded in them, these include home security lights, automatic doors and bathroom fixtures typically send out some type of energy, such as ultrasonic waves, microwaves or light beams and detect when the flow of energy is interrupted by something entering its path.

A photosensor:_ these types of sensors are widely used to detect the presence of visible light, infrared transmission (IR), ultraviolet (UV) or both.

Categories based on Application is as given below:

- Industrial process control

- measurement and automation

- Non-industrial use – Aircraft

- Medical products

- Automobiles

- Consumer electronics,and other type of sensors.

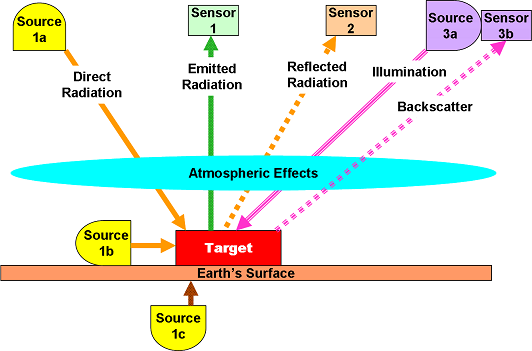

Active Sensor: these are sensors that require power supply. Examples are: Light detection and ranging (LiDAR), photoconductive cell. Passive Sensor - Sensors that do not require power supply are called as Passive Sensors. Example: Radiometers, film photography.

-Application of sensors In the future can be classified into groups as follows:_

Accelerometers: These are based on the Micro Electro Mechanical sensor technology. They are used for patient monitoring which includes pace makers and vehicle dynamic systems.

Biosensors: These types of sensor are based on the electrochemical technology. They are widely used for food testing, medical care device, water testing, and biological warfare agent detection.

Image Sensors: These are based on the crystal metallic oxide semiconductor (CMOS) technology. They are used in common electronics, biometrics, traffic and security surveillance and personal computer (PC) imaging. Biosensor: In biomedicine and biotechnology, sensors which detect, analyses a biological component such as cells, protein, nucleic acid or biomimetic polymers, are called biosensors.

This terminology applies for both in-vitro and in vivo applications. The encapsulation of the biological component in biosensors, presents a slightly different problem that ordinary sensors; this can either be done by means of a semipermeable barrier, such as a dialysis membrane or a hydrogel, or a 3D polymer matrix, which either physically constrains the sensing macromolecule or chemically constrains the macromolecule by bounding it to the scaffold.

In conclusion

The use of sensor cut across all sphere of lives such as your car, television set, mobile phone and many others, so it is imperative for us to know how it works and it application

Thanks for reading

Note: all pictures used in this post are labeled for free usage