INTRODUCTION

Power in general is of high demand as time goes on, that is the demand increases exponentially due to factors like increasing population and creation of more equipments which uses less energy but more are beung produced. Many facilities utilizes energy in form of electrical energy, moreover producing such electrical energy is a tedious work.

production of electrical energy can be in different forms such as solar and from an electrical generator(dynamo) which uses rotational motion to produce electricity through electromagnetic induction. This rotational motion can be generated from different mechanical machines like internal combustion engines and a gas power plant. The working principle of the internal combustion engines was explained in the previous post.

GAS POWER PLANT

This is a machine that produces both rotational motion and thrust (when needed) by expanding a high pressure hot gas (working fluid) on a turbine, The gas power plant is simply a machine that consist of a compressor and a turbine connected together with a single shaft, hence an intermediate combustion chamber in between fluit ducts connecting the compressor and turbine.

MAJOR PARTS OF A GAS POWER PLANT

▪THE COMPRESSOR: A compressor is simply a device that increases a fluid pressure by increasing the flow velocity and volume flow rate while reducing its volume. The compressor is synonymous to a pumpin that it is basically made of axial blades in a drum or shaft in a close case with an inlet duct and an outlet duct. it can also ve a reciprocating compressors which uses pistons driven by a crankshaft.

▪THE TURBINE: It is a rotary mechanical device that extricate energy from a fluid flow and convert it into a useful work. The turbine is basically a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with axial blade attached. The fluid is expanded on the blade which cause the shaft to rotate.

▪THE COMBUSTION CHAMBER: It is an enclosed space or region in which combustion takes place, especially in an engine but in this case it is like a furnace. the combustion chamber is located in between the compressor and the turbine.

▪THE SHAFT: A shaft is simply a rotating machine element which is circular in section and it is used in transmitting power from one part of machine to another.

WORKING PRINCIPLE OF A GAS POWER PLANT

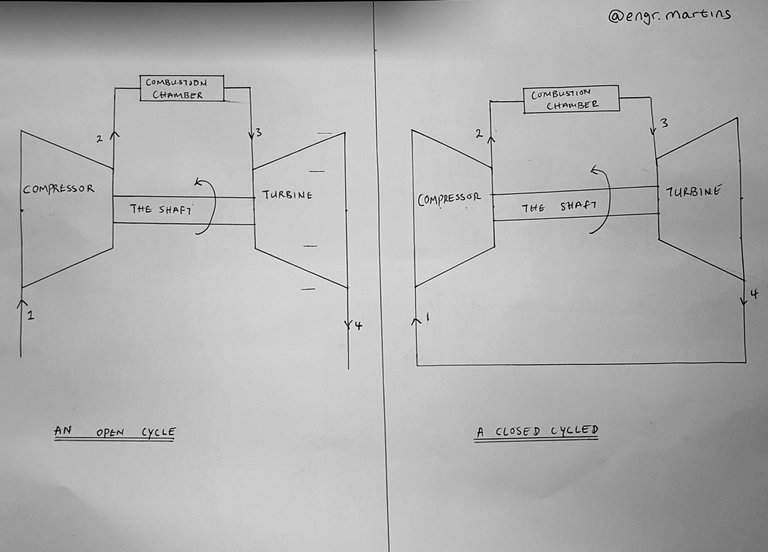

As explained earlier in the previous post about thermodynamic cycle, using a series or combination of processes to transform energy hence extracting the excess energy in the process which is called the net work. A gas power cycle can either be an open cycle or a closed cycle.

In a close cycle, the working fluid is returned to the initial state at the end of the cycle ans is recirculated while in the open cucle, the working fluid is renewed at the end of each cycles instead of being recirculated.

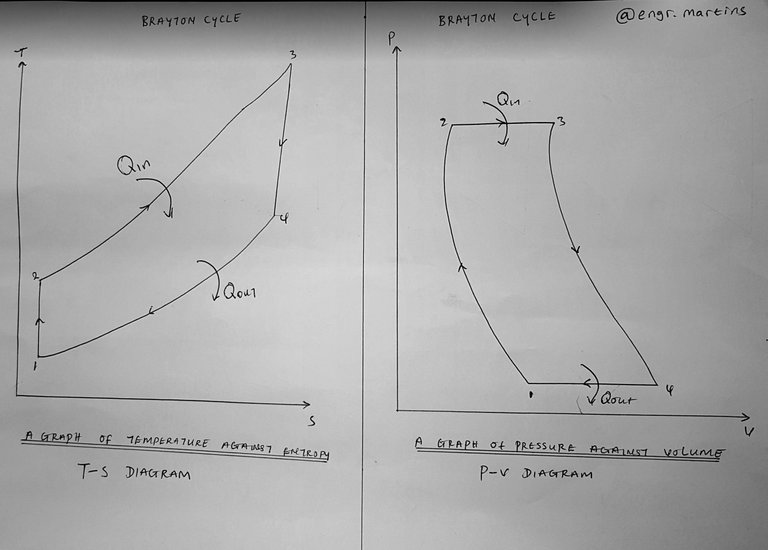

The ideal gas power cycle works on the BRAYTON CIRCLE which was proposed by GEORGE BRAYTON 1870

It is a model for creating of designing a gas power plant.

▪1-2: Isentropic compression (in the compressor)

▪2-3: Constant pressure heat addition ( in the combustion chamber)

▪3-4: Isentropic expansion (in turbine)

▪4-1: Constant pressure heat rejection

In a simple way, this process can be explained; the air enters the compressor at a very low pressure and the pressure is increased due to reduction in volume as pressure in inversely proportional to volume. the compressed air enters the combustion chamber where it mixes with a very inflammable gas and then it combust due to self detonation or a spark mechanism. The hot gas is then expanded on the turbine, the working fluid (hot gas) at high pressure causes the axial blades to move which then causes the shaft to rotate and the exhaust gas id release from the exhaust duct, hence can be recycled depending whether it is closed or open cycle.

Since the rotating shaft connects the compressor and turbine, the shaft powers the compressor causing it to compress more air and the cycle kepts on running provided there is a constant air and fuel mixture. the air fuel ratio is about 90:1 for normal gas power plant.

LIMITATIONS TO GAS POWER PLANT

▪METALLURGICAL LIMITATION: Due to the fact that the gas power plant is a high temperature machine especially at the combustion chamber and the expansion of gas at the turbine, the temperature is limited to some certain level to reduce risk of creep failure hence decreasinh its efficiency.

▪A spontenous increase in speed of the machine due to increasing supply of air and fuel which can cause a corresponding increase in speed and temperature as such it can lead to creep failure. It can be controlled by controlling the runaway on the fuel supply line which limit the amount of fuel fed to the combustion chamber which in turn reduces the speed.

ADVANCES IN A GAS POWER PLANT

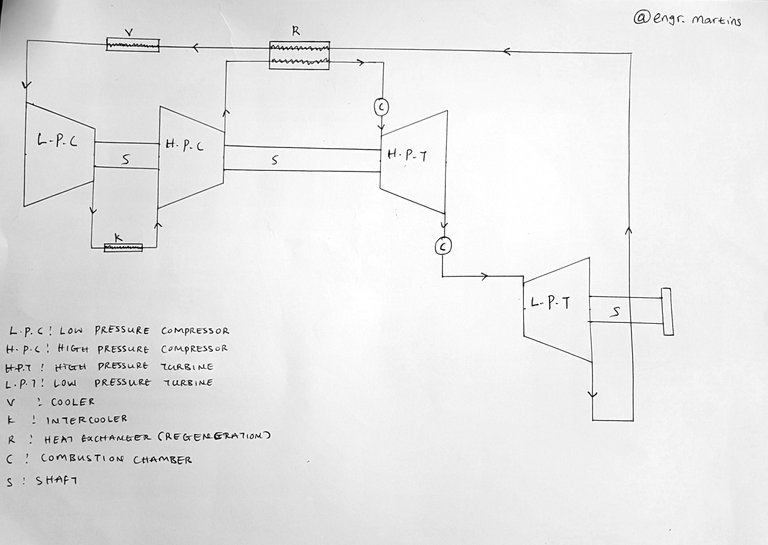

•LOW PRESSURE COMPRESSOR AND TURBINE: A low pressure compressor is a pre-compressor which is located behind the main compressor called the high pressure compressor. It function is to increase the pressure of air to some certain level before the main compressor can compress it to the required pressure, this is done so as to reduce the work load of the main compressor. It is connected to the main compressor and the main turbine with a single shaft.

A low pressure turbine is a turbine which sole aim is to reduce the work load of themain turbine or the high pressure turbine which drives both the low and high pressure compressors. It is located after the main turbine and has a single shaft of its own which produces the net work. More over the exhaust fluid of the min turbine works on it when it is reheated.

•INTERCOOLING: A conpressor in a gas turbine cycle utilizes the major percentage of power developed by the gas turbine. The work of the main compressor can be reduced by sharing the work load into two stages hence providing an intercooler between them.

•REHEATING: The output of the gas main turbine can be simply improved by expanding the gas in two two stages with a reheater in between the two stages.

•REGENERATION: The exhaust gases from the gas turbine carry a large amount of heat with it since the temperature is far above the inlet temperature, they can be used to heat the air coming from the compressor thereby reducing the mass of fuel supplied in the combustion chamber.

APPLICATION OF GAS POWER TURBINE

▪It is used in powering an electrical dynamo

▪It finds application in jet engines in air plane and jet, in jet more thrust is need rather than rotational motion, that is the force exerted by the exhaust gas is neccessarily high to produce high thrust to cause a controlled up lift.

REFERENCE

▪Engineering thermodynamics:

Power generation as a whole is one interesting aspect of engineering. I have been in a steam plant for some months and we use a gas turbine for black starting. You've have really done well to give a comprehensive writeup on gas power plant.

Great work!

thank you... thanks for going through my post, indeed gas power plant finds its application in various huge machines.

It's my pleasure to have an Engineer around.

Awesome brush down on the gas power plant. Power generation remains one of the aspect we'd keep working on as electricity is important everywhere...

Nice input.

Thanks, Advancing gas power turbine will bring about an efficient production of power with limited resources.

Well said. It has really been a major contributor to power in Nigeria, in terms of the Egbin power station.

i would like to get in touch to u, from an engr. to an engr. wahh do u think?

I wouldn't mind. We could chat up on discord... Are you on steemstem discord server? You could chat me up there....