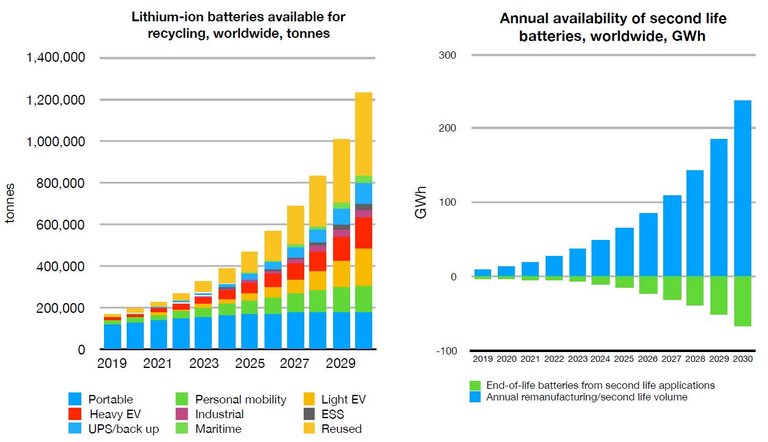

According to data released by Circular Energy Storage, a London-based storage recycling research organization, 1.2 million tons of lithium-ion batteries will reach their end of life in just a decade.

Circular Energy Storage estimates that by 2030, the recycling facility will recover 125,000 tons of lithium, 35,000 tons of cobalt and 86,000 tons of nickel. Based on the current price of these materials, this will add a $6 billion market. The researchers said that the most important thing is that they can recover 400,000 tons to 1 million tons of production waste.

The massive use of lithium-ion storage in portable electronics, transportation and energy applications continues to accumulate for the recycling industry of such products. Between 2018 and 2030, the market size of such batteries may expand tenfold.

China is the world's largest battery manufacturer and its own best customer, because by 2030, China will produce 57% of battery waste. The business community is no stranger to this, and 30 of the world's 50 lithium-ion battery recycling experts are based in China.

In addition, by 2030, the battery recycling market will reach 1 TWh, and its service life will make the battery unavailable for its original use, but it can still be used to provide backup grid power, stationery storage and electric vehicle charging.

“1 TWh sounds like huge capacity, far beyond the expected installed capacity of, for example, energy storage systems,” said Dr. Hans Eric Melin from Circular Energy Storage. “But once again, by 2030, such two The net market value of secondary battery applications is estimated at $45 billion, based on the assumption of $45/kWh, half of which will be generated between 2027 and 30 years."

Light-duty electric vehicles account for the majority of the current production of lithium-ion batteries, but in the near future, the batteries used in heavy-duty electric vehicles (such as trucks and buses) will dominate the amount of such materials entering the recycling market. In such frequently used vehicles, the battery is subject to more wear and can only be recycled after it has reached the end of its useful life. However, batteries used in light electric vehicles may have a second lifespan, delaying their entry into recycling time.

The rise of battery-based energy storage has raised new concerns about the environmental and social impacts of lithium mining, especially considering the technical challenges of recovering battery-grade lithium from used equipment. However, recent process developments have shown that the material can be recycled to a high enough standard for reuse in batteries.