In the UK, a technique for 3D printing of human tissues with a relatively soft structure, for example, lung or brain tissue, has been developed. For printing it was suggested to use the technology of freezing the material with "dry ice".

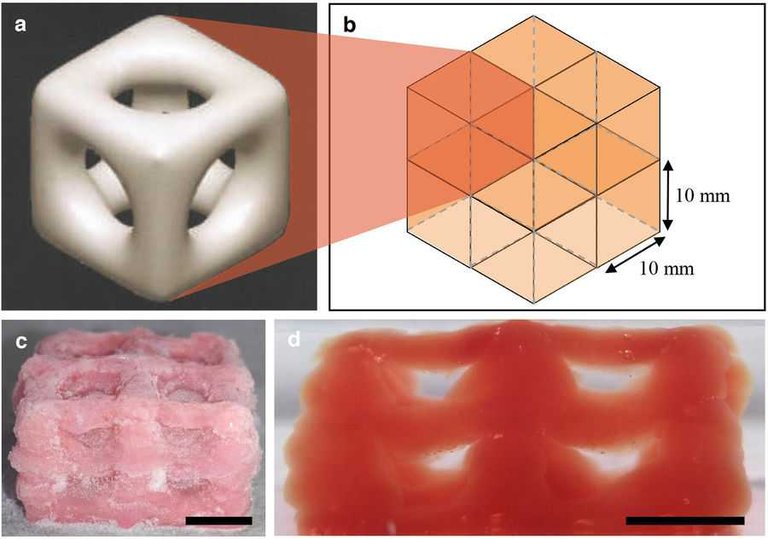

Researchers from the UK proposed a new technology of 3D-bioprinting, which will artificially reproduce soft structures of the human body, similar to brain or lung tissue. To ensure that the printed fabric does not sag under its own weight, the developers suggested freezing the lower layers of the material with dry ice.

In some cases, artificially created organs will avoid rejection and an increased risk to the patient. For most 3D-bioprinting methods, living cells are laid on a solid "skeleton" that reproduces the structure of the desired tissue. Therefore, in this way, only relatively dense organs, for example, the liver or kidneys, can be printed.

The "skeleton" for soft tissue was created from a composite hydrogel. It consists of polyvinyl alcohol (water-soluble thermoplastic polymer) and gellan gum (gelling thickener). The authors of the new technique say: the main problem with printing soft fabrics is the difficulty in layering the base material.