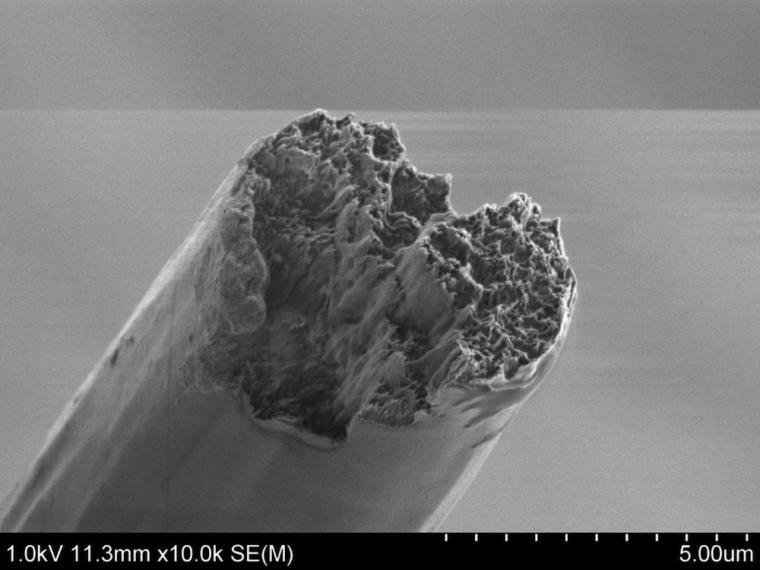

These artificial cellulose fibers created by a team of Swedish researchers are more resistant than steel and spider silk.

l

They manufacture the strongest biomaterial in the world

Spider web is the most resistant natural fiber that humans know, even more than steel. Knowing this fact, we can assess in its true measure the prowess of a team led by Swedish researchers that has manufactured the strongest biomaterial that has ever been produced: because these artificial but biodegradable cellulose fibers are more resistant than steel and even that the spider silk.

This group of scientists, headed by Daniel Söderberg, of the Royal Institute of Technology (KTH, for its acronym in Swedish) -university based in Stockholm, has just reported the results of their study through an article in the journal ACS Nano, from the American Chemical Society. The researchers have worked in collaboration with German colleagues of the DESY - or German Synchrotron of Electrons -, the largest German research center for particle physics, with headquarters in Hamburg and Berlin.

The ultra-resistant material they have made is made of cellulose nanofibers, a structural polysaccharide in plants - it forms part of the supporting tissues. Through a new production method, these Swedish researchers have successfully transferred the unique mechanical properties of these nanofibers to a macroscopic material - seen with the naked eye, without the help of a microscope - and very light that could be used as an alternative ecological to create the plastic that is used in the manufacture of aircraft, cars, furniture and other products. "Our new material has potential even for biomedicine," explains Söderberg in a press release published by the DESI.

With the help of the ultra-bright X-ray source Petra III, located at the DESY research center in the city of Hamburg (Germany), the scientists were able to follow and optimize the process used in this study. "X-rays allow us to analyze the detailed structure of the yarn as it is formed, as well as the structure of the material and the hierarchical order of the super-strong fibers," explains study co-author Stephan Roth of the DESY. "We made threads up to 15 microns thick and several meters long," he adds.

Eight times stronger than spider silk

For his part, Söderberg notes: "The nanocellulose fibers of biological origin that we have manufactured are eight times more rigid and their resistance is higher than natural spider silk fibers." "If you are looking for a bio material," continues the Swedish scientist, "there is nothing like this, and it is also more resistant than steel and any other metal or alloy, and glass fibers and most other synthetic materials. "

These artificial cellulose fibers can be woven into a fabric to create materials with many different applications. And, in addition, the scientists who have manufactured them consider that the production costs of this new material can compete with those of synthetic fabrics. "The new material can be used in principle to create biodegradable components," adds Roth.