Having previously looked at the Nickel Sulphate used in the foil making process, and the Nickel powder, used in the fuel, we were impressed with their purity, so what of the other major transition metal component in the fuel mix, Titanium, how does it stack up?

Titanium is a very well known elemental hydrogen storage transition metal and it has been reported regularly to be LENR active, particularly by Russian researchers. It is no surprise then that Suhas Ralkar would consider it as a fuel component for his ECCO device.

The Titanium powder, thought to be around 80-100 um was placed on a piece of carbon tape, that was then attached to the SEM table.

The first question that springs to mind is, why is this Titanium reddish in colour?

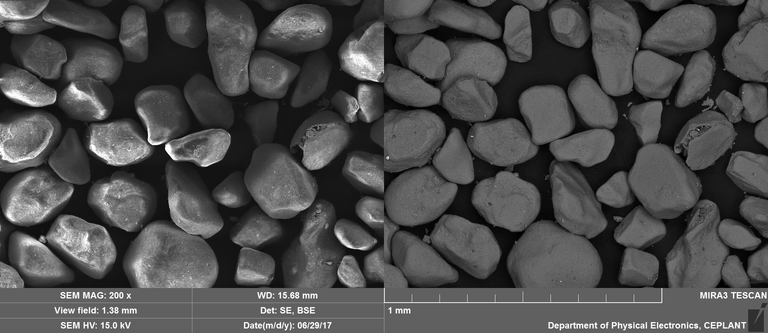

Under the microscope

The actual size of the particles was between 100 to 400 microns, far outside the 80-100um quoted. There was a very small proportion of the bulk mass that were smaller particles but hardly worth considering. What is going on when a supplier is quoting particle sizes so far removed from the actual size of the supplied material.

Their appearance is of smoothed rock fragments with the occasional fracture.

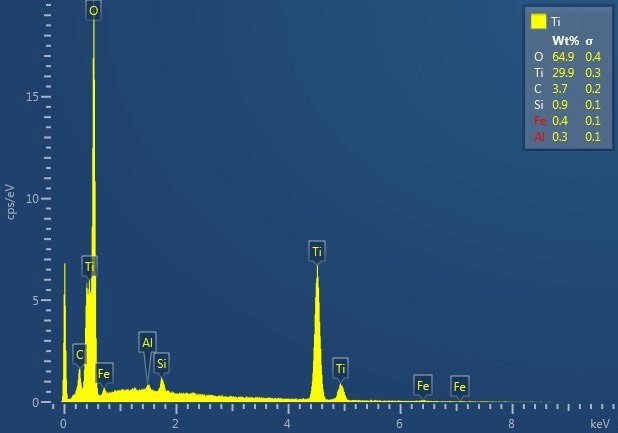

Elemental composition

Titanium passivates in air like Aluminium, immediately forming an oxide layer, Wikipedia adds more detail:

When it first forms, this protective layer is only 1–2 nm thick but continues to grow slowly; reaching a thickness of 25 nm in four years.

So, if you don't want to have oxygen in your fuel, it is important to know how old your powder is and have some method for reducing it.

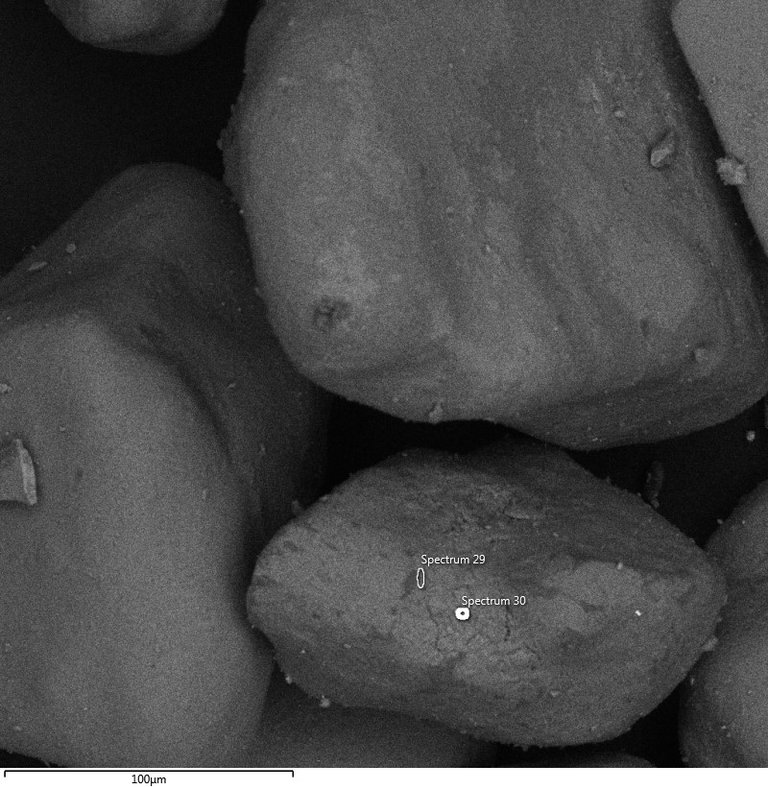

There was three other elements indicated in the sampling, two of them, Iron and Aluminium were out of range on the sensitivity of the EDX, however, Silicon was detected with sufficient strength to add into the table of detected elements. This deserved further investigation, more so, because if you looked at the above SEM backscatter image (the one on the right), there appeared to be small particles that were very bright, and this indicates a heavier or more noble element and so we decided to go into a grain sporting these flecks to see in more detail what they were.

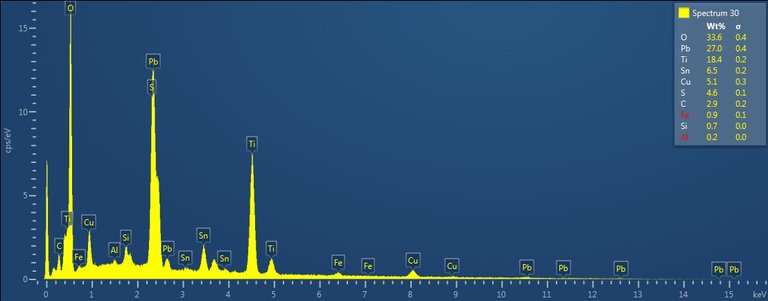

Spectrum 29 taken as a control was essentially Titanium Dioxide/Titanium, however, spectrum 30 of a 'bright fleck' was more interesting.

The EDX of the bright fleck contained Lead, Titanium, Tin, Copper, Sulphur, Carbon and Silicon.

Discussion

The bulk of the material here was likely Titanium with an oxide layer, however, the size of the particles were not as specified. More concerning is that there is clearly contamination. When we previously analysed part processed fuel, we found that it was predominently Titanium, Lead and Zirconium, Tin was sometimes detected but below error threshold.

There was some speculation that some PZT from ultrasonic transducers had contaminated the part processed fuel we previously tested, however, we are not seeing the Zirconium in the Titanium contamination above and we are seeing copper which was not present in the part processed fuel. Also, there was Niobium in the part processed fuel which is not in the Titanium. So was a different source of Titanium used for that fuel and/or was it exposed to other contamination in preparation.

Whatever the cause of the contamination, lead oxides can be yellow and red and perhaps the colour of this Titanium as shown in the photograph at the top of this article, is due to some combination of a very fine and thin layer of lead oxides, perhaps just a few molecules as if left by liquid - what do you think is going on?

Conclusion

The Titanium sample supplied by Suhas Ralkar has some contamination, however, it does not account for the elements and their relative quantities found in previously analysed part processed fuel. It remains to be determined if this is due to the supplier, or is a result of some other source/handling procedure during the chain of custody from supplier to our testing. If, indeed Suhas Ralkar's ECCO device delivers excess heat, could it be due to this minor addition of contaminant elements, or in spite of it?

As an aside, Titanium is produced and sold for many uses as a non-toxic whitener in the form of Titanium Dioxide including for sunscreens, cosmetics, toothpaste, pill filler etc. It is concerning that this product contains toxic tin and lead and if it is processed into Titanium Dioxide for topical skin application or oral consumption, then there could be serious health issues associated with its use, if this is as it comes from the supplier, they need to be notified.

If you want to be automatically notified as soon as a new blogpost is made, please follow. Also, please up vote and re-steem the article as it will help get exposure for the New Fire. If you are here just browsing, you really should get a steemit account, as it is the fastest way to responsive, advertising free blogging and you can earn real money by helping to build the network - you can also earn money for just commenting on another contributors blog, the secret is, write quality content and comments and then others will up vote you.

It seems that the fuel parameters provided by Suhas are in conflict with the actual situation.

He is reporting the specification as provided by the suppliers.

We have ordered things in the past, such as 'pure nickel foil' only to find out it is steel foil.

However, could the 'errors' be key to it working... or just errors.

The grain size of the Nickel Sulphate does not matter since it will be dissolved in de-ionised water, it had high purity. The Nickel powder was arguably showing a mean or mode that matched the suppliers claims and the supplier wasn't claiming a particular surface structure or process, and since Suhas processes it for 100 hours, the scale here is not important. The nickel was highly pure.

The Titanium likewise is to be processed down in scale, however, it needs to be established where the contaminants in this sample originated.

The color of the titanium powder seems a little red. It may have been oxidized

Yes, oxides are observed.