Scientists are working to further develop a 'enzyme' containing a plastic bacteria that is seriously damaged by the natural state of the enzyme, which is being used for plastic degradation.

Plastic bottles are often referred to as "PET", a solid plastic, which takes hundreds of years to decompose.

The same enzyme, "PETase", which scientists are further developing, will begin the plastic decomposition within a few days.

The enzyme helps to make a revolutionary change in the plastic recycling process, making it possible to reuse them.

Enzymes hidden in a jungle

This enzyme, which is used for PET-plastic degradation, is made of plastic "edible" bacteria, first recognized in Japan.

'Ideonella sakaiensis' is a Japanese company that uses its main energy in the form of plastic.

The PETase enzyme bacterium was discovered in a sludge slab in the plastic containers that had been bottled to recycle them, according to an investigation report released in 2016.

Over the past 50 years, "the use of PET plastics has been greatly increased," says Professor John McGuigan, who is currently in the test, "but this time is not enough to grow bacteria that are consumed by humans."

Polyethylene terephthalate (PET) is called polyurethere, or 'polyethylene terephthalate', which is also a natural substance produced in the natural environment.

Polyester protects the leaves from trees. The bacteria are growing for millions of years to eat it, "explains a researcher at the University of Potoscope.

However, the PETase enzyme has been started by PET plastics in an "unexpectedly" period, and a group of international scientists are continuing to further investigate the evolution of enzymes that digest digestion.

Plastic eating

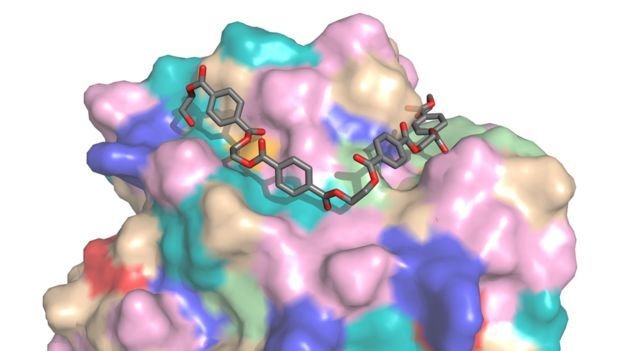

The team of investigators was able to create a 3D image of the enzyme using the powerful X-rays.

This 3D image helps identify the location of the PETase enzyme. Scientists have observed that enzyme activity can be enhanced by reshaping some of its outer layers.

David Shukman, editor of BBC Science Section

"The team of students at the University of Portland include both PhD students and GPs, and I saw the group's enthusiasm for the experiments when they went to the lab."

David Shukman also notes the following.

"They knew that creating an enzyme that supports the process of decomposing millions of bottles of plastic bottles is a very important task, since it's time that plastic surgery has become a threat to the world, and it seems that they are very keen on this discovery.

However, it is a great challenge to introduce this test into the ordinary world.

The first challenge is to develop a PETase enzyme at a minimum cost, and secondly to develop it as an industry.

This is a very rapid scientific process. The plastic bacteria that have been bacteria have been evolving for decades, and it's noteworthy that enzymes have been identified to digest their digestion.

Refined enzymes can be expected to produce more results. The scientific answer by now to stop the damage to nature from non-decaying plastics will be "

'Enzyme manufacturing industry'

In factories, 'Polyester' is produced using petroleum, and used in the production of plastic bottles and fabrics.

Use of PETase enzyme will lead to a reversal of 'Polyester' production. The plastic can be degraded by the activity of the enzyme because it can be used repeatedly after the recycling process.

However, it will take several more years to unveil a developed enzyme industry.