The Infrared (IR) method of measuring gas concentration is based on the absorption of IR radiation at certain wavelengths as the radiation passes through a volume of the gas.

There is an excellent whitepaper Infrared Technology for Fail-To-Safe Hydrocarbon Gas Detection by Dr. Shankar Baliga and MSc. Shaquif Khan, that explains the subject in a clear and elegant manner, partially quoted below:

Instruments based on IR technology use two wavelengths, one at the gas absorbing wavelength and the other at a wavelength not absorbed by the gas; neither wavelength is absorbed by the other atmospheric constituents such as water vapor, nitrogen, oxygen, or carbon dioxide

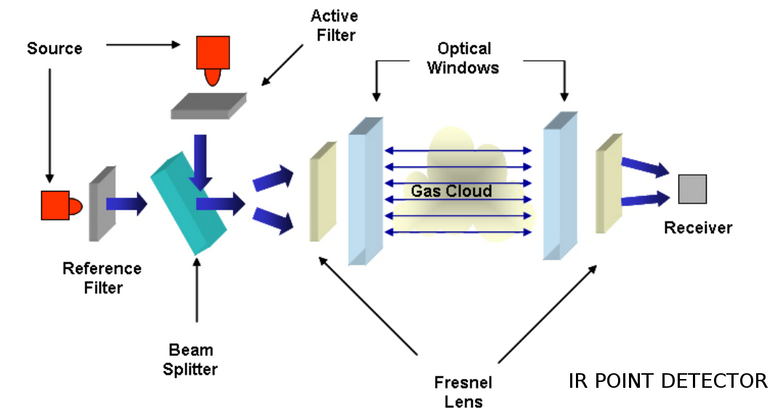

POINT IR DETECTORS: In the point IR detector, the concentration of hydrocarbon gas is measured via the infrared absorption of an optical beam known as the active beam. A second optical beam known as the reference follows the same optical path as the active but contains radiation at a wavelength not absorbed by the gas.

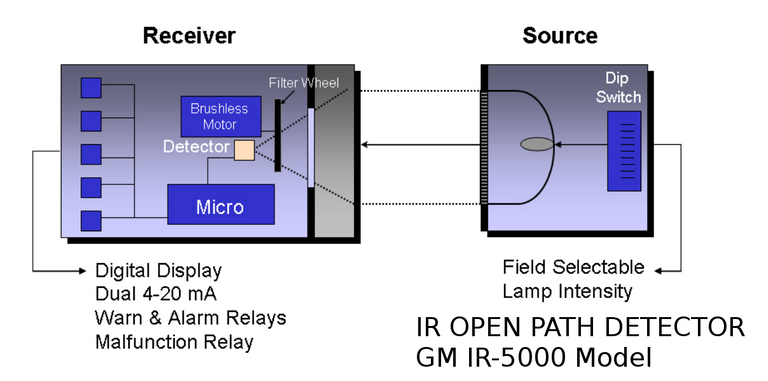

OPEN PATH IR DETECTORS: In open path IR gas detectors, the concepts of the point IR detector are expanded to a gas sampling path which can be as long as 130 meters as opposed to a few inches internal to the instrument. These systems can either use a retro-reflector or use separate IR transmitters and receivers housed in explosion-proof housings

IR features and advantages includes:

- Immune to poisoning agents

- Immune to contamination in harsh environments

- resistant to corrosion

- Immune to oxygen deficient (or surplus) atmospheres

- calibration free

- fail-to-safe operation mode in presence of obstruction in optical path

- sensor life span not affected by normal maintenance operations.

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://instrumentationtools.com/point-ir-detectors-vs-open-path-ir-detectors/