We are presenting about a plywood business, because we this type of business is quite interesting and we git approvement from our lecturer so we proceed it . We explain about the company backgroud, process and so on.

First of all we explain about ,

BUSINESS OWNERSHIP

LKM Plywood & Timber Sdn. Bhd. Kuantan is a cooperation business runs by Mr. Lai Yin Tjun. They choose cooperation business because the members of cooperative business pay lower or stabilized prices for products and services. Benefits are distributed to members based on usage of the cooperative’s products or services. A member who purchases 10 percent of the products or services receives a return of 10 percent in benefits. Furthermore, they also can continuity of life. So the risk of the factory to closed is low. A corporation stays in business even though owner or its officer dies or retires. It may continue to exist more than 100 years.

MARKET MODEL

It is not easy to maintain good reputation and performance in supply plywood in Malaysia and international. But Mr. Lai Yin Tjun and his workers have prove that hard work and passion in business will reward success to their business. The type of this firm market model is monopolistic competition. The characteristic of this market model is large number of buyer. The product has high demand from contractor to build house and building. This firm supply it product both domestically and abroad. This market model also has large number of seller. Mr. Lai said the market is very competitive because there are many plywood suppliers such as Mentakab Veneer & Plywood Sdn. Bhd. , Songsang Plywood (M) Sdn. Bhd. And ect. There are almost 20 competitors in the market. Lastly, the characteristic is price maker. Mr. Lai has considerable control over price because it is responsible for the total quantity supplied.

CHARACTERISTICS OF ENTREPRENEUR

The owner possesses the characteristic of a successful entrepreneur as he is a determine person to achieve goals. Mr Lai had achieved business goal to promote the goods abroad. There is demand of plywood from Thailand, Hong Kong, Africa and Mexico. Other than that, he is persistent toward problems solving. He always find a way to solve problems that occur in the business such how to delivery goods because the firm does not owned a lorry, he paid carriage outwards to delivery goods. The entrepreneur characteristic is caring person. Every morning, he always visit his factory to make sure the employees doing their work and in a good condition. Besides, the characteristic that the owner shown is integrity and reliability. The firm is free from bias and corruption because Mr. Lai is has high integrity value.

THE IMPACTS OF EXISTENCE OF THE BUSINESS TOWARDS ENVIRONMENT

The existence of LKM Plywood & Timber Sdn. Bhd. give the surrounding good impact. The good impact is this company give the job opportunity to the community in that particular area. This can reduce unemployment problem. Most of the workers live near the factory. Those workers benefit is they can save money because the cost of transportation to work place is low.

CONTRIBUTION FOR SOCIAL RESPONSIBILITIES

LKM Plywood & Timber Sdn. Bhd. is very responsibility toward the environment. Responsibility toward the environment could be implemented by controlling pollution such as air pollution. The factory releases a clear smoke. The plant only releases amount of smoke released that set by the environmental department.

The company is also very responsibility toward employees safety. Employee safety can be improved upon by closely monitoring the production process to provide a safe working environment. This will minimize on-the-job injuries and improve the morale of the employees. The risk of this plywood and timber plant burning is high. The company has tightened non-smoking regulations in the factory area. The workers who smoke in a factory outlet will be subject to disciplinary action and may be dismissed.The company also provide fire extinguisher for employees safety.

LEADERSHIP STYLE IMPLEMENTED BY ENTREPENEUR

Leadership is both research area and a practical skill encompassing the ability of an individual or organization to lead or guide other individuals, teams or entire organizations. To strengthen the business, the entrepreneur must reinforce their leadership. The leadership style implemented by Mr. Lai Yin Tjun is participative. Participative often called the democratic leadership style. Participative leadership values the input of team members and peers, but the responsibility of making decision rests with the participative leader. Participative leadership boosts employee morale because employees make contributions to the decision making process. It causes them to feel as if their opinions matter. When a company needs to make changes within the organization, the participative leadership style helps employees accept changes easily because they play a role in the process. This style meets challenges when companies need to make a decision in a short period.Mr. Lai Yin Tjun is a leader who will consider the ideas of his workers. One of his employee idea is to increase the production.

PRODUCT AND PRODUCTION PROCESS

Product

This firm produce plywood. There are three grade of plywood, BBCC, UVL and SV. But this business only produce two grade, BBCC and UVL. BBCC is the highest quality while UVL has higher quality than SV.

Production processes

- Selecting log and conditioning

To produce the plywood , the company choose timber as their raw material . Log will be identified in form of the log species and the quality. Usually they will use ‘Gluta Spp’ as know as ‘Pokok Rengas’. To reduce transportation costs in a grave economic situation, this company has taken a wise way of taking resources from nearby areas such as Sungai Lembing and Rompin . Conditioning is process of spraying water to make the log soft and become easy to cut .

- Cutting and debarking

The log will be measured and cut into a specific length. Once log have been cut to a specific length, the bark will remove using a debarking machine. Debarking process also aimed to improve roundness of the log.

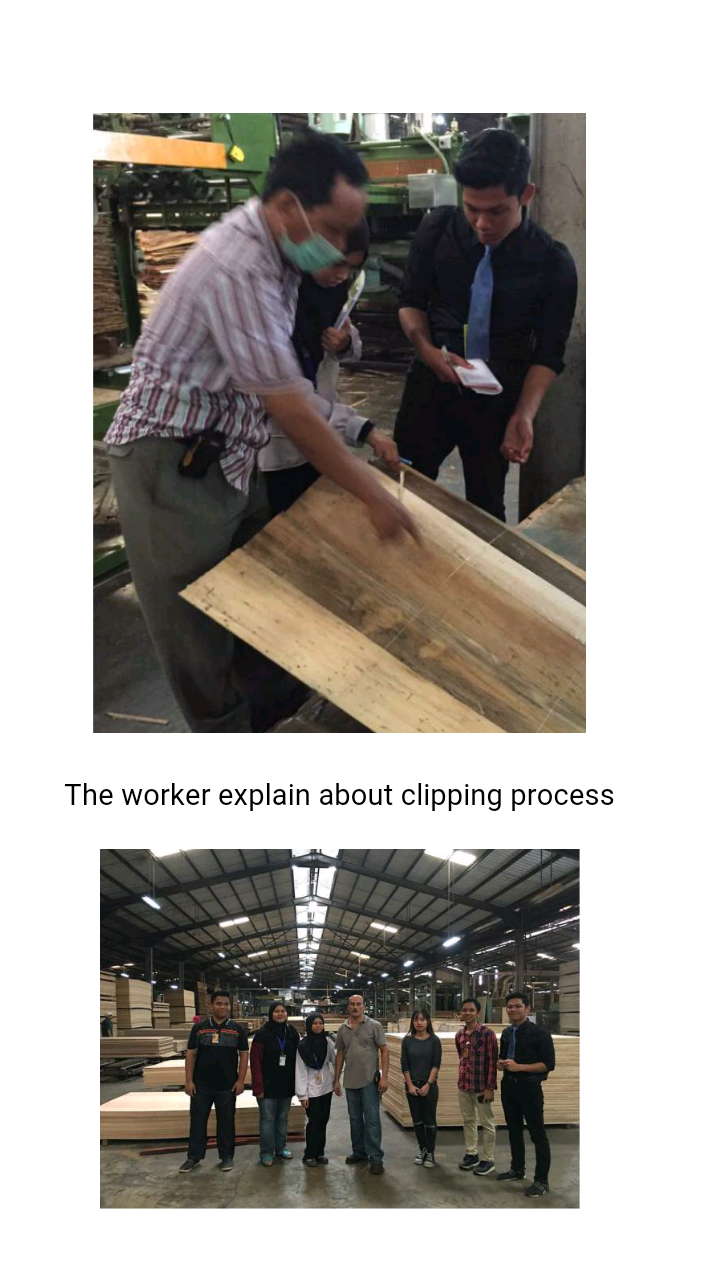

- Peeling and clipping

Log will be peeled into thin veneers by using a rotary machine. Veneer will come into a continuous sheets and will be slice using a veneer slicer, or it will immediately clipping the veneers up into a predetermined width and length. Small size veneer will join together to form a standard 4f by 8f or 3f by 7f .This is clipping process to merge the short veneers.

- Drying the veneers

This process is necessary to improve the bonding and it done by a drying machine. The drying produce heat from the steam boiler that are fulled by barks, sawdust and the rejected veneers. This process is also to prevent fungal growth.

- Composing the sheet

After properly drying and trimming the veneers, they are then composed into final 4×8 sheets. At this stage, segregated as face, core or back veneers. The face is the surface that is to be used or seen. The back, as the term suggests, is the part that remains unused or hidden. The core, refers to the center layer. The process is meant to make composing the plywood layout easier. The plywood layout, for its part, will be controlled in terms of thickness, timber grain orientation, wood species, and the quality of the ply.

- Composing process to segregated as face, core and back

Example of 5 ply plywood

The flawless sheet should be a face while the flaw sheet should be core. This is because the flaw can be hidden

- Bonding using adhesive

Once the sheets are properly composed, they are then bonded with the use of adhesives urea formaldehyde resins-typical used are typically used. To make sure that the adhesive is evenly spread on alternate layers of veneer, mills pass the veneers through a mechanical glue spreader. This will then be followed by composed them into panels in odd numbered layers. The thickness of the final plywood product will be determined by the number of veneer layers.

- Cold press and hot press

The composed panels are then pre-pressed in a cold press at an ambient temperature and a controlled hydraulic pressure. This process usually takes 20 minutes. Helps flatten the plywood. Hot press to excellent their bonding,time taken depend on wood species. It usually take time 5 to 7 minutes.

- Quality check

After the pressing process, the panel is ready for quality control. Samples will be randomly picked and tested for mechanical strength, bonding strength. A visual check will be performed, and there should not be any hole or the hole will be filled with putty.

- Sanding and trimming

After pass quality check, sanding process to make the plywood surface smooth and uniform it thickness. The plywood sanded depend on market specification, both or only face or back. After sanding, the plywood will then be trimmed to its final size.

We are not allowed to see the sanding and trimming process for our safety

Packing, stacking and stamping

Finally, the finished plywood will be packed, stacked and stamped accordingly for shipment to both local and overseas markets. Stamping will indicates grade of the plywood, the stamping is using by the company to make their brand awareness .

TRAINING DEVELOPMENT AND COMPENSATION BENEFITS OF COMPANY TO THE EMPLOYEES

Training and development is a necessity in a company because it is a way in which the Human Resources Manager develops the necessary job skills to the employees.

The training was provide by the firm is on the job training. Since the many factory employees do not have any skills in this industry, the manager teaches the employees about the process when the employees on the job.

Compensation represent the total financial and non financial compensation and benefits offered to employees.

The company provide salary minimum RM 1000 exlude overtime payment to the factory workers. The company also provide KWSP, HRDF, and SOCSO to their workers. Perks are special privileges or benefits often offered to high level employees. The firm provides the covered car parks to the managers. The marketing team will received commission if they achieved targeted sales. The business also provide benefits such as paid vacation. Last year the workers went to Pulau Langkawi to celebrate family days.

DISTRIBUTION CHANNEL SELECTION

The distribution channel used by the firm is direct channel. Direct channel happen when a producer deals directly with customers, without using intermediaries. The customers are mostly contractors. The contractors need the supply of plywood to build something such as furniture, house and building.

SOURCE OF FINANCE TO RUN THE BUSINESS

Next, source of finance is the most important thing to run the business and ramp it up to profitability. The financial needs by a business is according to the type and size of the business. The business cannot be operate if the modal is not sufficient. Having known that there are many alternatives of finance or capital, a company can choose from.

They started the business with the capital that contribute by the stockholders. The stockholders are among the family members.

The assets of the company are :

- Land

- Factory

- Premise (Office)

- Trade Mark

- Forklift

- Machine

- Factory

- Premise

- Trade Mark

- Forklift

- Machine

RISK OCCURRED AND RISK MANAGEMENT

Risk is an uncertain future condition which if happens affect the mission objective. It could have a positive or negative effect. The two type of risk are speculative risk and pure risk. Speculative risk refers to exposures or actions taken that may result in a possible gain or loss while pure risk or unexpected risk involve the possibility of no change or a loss with no potential for a gain.

Risk management is a logical process or approach that seeks to eliminate or at least minimize the level of risk associated with a business operation. Identifying risk and potential losses, measuring the frequency and the impact of the losses and evaluating alternatives and select the best techniques are include in risk management steps. There are many techniques to handle the risks such as risk avoidance, hazard prevention, risk reduction, risk sharing and risk retention.

A risk that occurred is cost of transportation. This business does not have its own truck for delivery goods to the customer. So, the business has to pay the cost of transportation. The technique the firm use to handle this risk is risk retention. Risk retention involves accepting the loss, or benefit of gain, from a risk when it occurred.

Next, the risk occurred is machine obsolescence. The machine is not working properly and the machine useful life is almost 40 years. The technique the firm use to handle this risk is risk avoidance. Risk avoidance includes not performing an activity that could carry risk. Mr. Lai Yin Tjun decides not to buy any new machine because that may result in possible big loss and it is not worth to buy because the firm suffer from lack of timber resources.

After that is the fall of Ringgit Malaysia value. The business gain a little profit from sales in Malaysia. But if they supply their product to the country, the business will gain more profit. Mr. Lai decides to market the product to Mexico, Thailand, Hong Kong and Africa.

Risk that faced by the business is lack of timber and the size of the timber is getting smaller. The business plan to plant the tree itself.

The risk of this plywood and timber factory burning is high. The company use risk reduction technique. The company has tightened non-smoking regulations in the factory area. The workers who smoke in a factory outlet will be subject to disciplinary action and may be dismissed. The company also provide fire extinguisher for employees safety.

Lastly, difficult to get factory workers is also the risk that occur in the firm. This because the locals are not interested working in this industry. The solution are Mr. Lai decides to import foreign workers from Bangladesh, Myanmar and Indonesia and offers a high salary to the locals.

STRATEGIES TO IMPROVE BUSINESS FOR THE FUTURE

Mr. Lai Yin Tjun plan to plant trees itself. It is because he want to produce quality trees to improve the quality of plywood production.

The owner also plan to give discount to customers. Since there are many competitors, Mr. Lai must compete the competitors price. This will attract the customers and gain profit.

Mr. Lai also plan to market the product to Europe because the demand of plywood are high because there are many building to built. The business will gain more profit.

CONCLUSION

In conclusion, we get many knowledge from this firm. We also know the process and procedure how to make plywood, assess plywood quality as our additional knowledge. We also learn how to manage a firm from their dedicated employees, example how to train workers, compensation and worker safety.

@originalworks

The @OriginalWorks bot has determined this post by @zouxx to be original material and upvoted it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!