Late last year I decided it was time to get myself a 3D printer, of course with so many options out there it's good to have guidance when getting started. Thankfully I met @themarkymark in our community who shares a lot of information about his experience with 3D printing and was kind enough to give me a crash course.

With options ranging from ready-to-print out of the box systems to build it from the ground up DIY kits, you will have to decide on where you fit in that range of tinkering skills. Myself, I am a very hands on type of person when it comes to building things and taking things apart just to see how they work - this drove my parents nuts when I was a kid.

In time they learned not to panic when the VCR was sprawled out across the living room floor knowing I would put it back together later in the day.

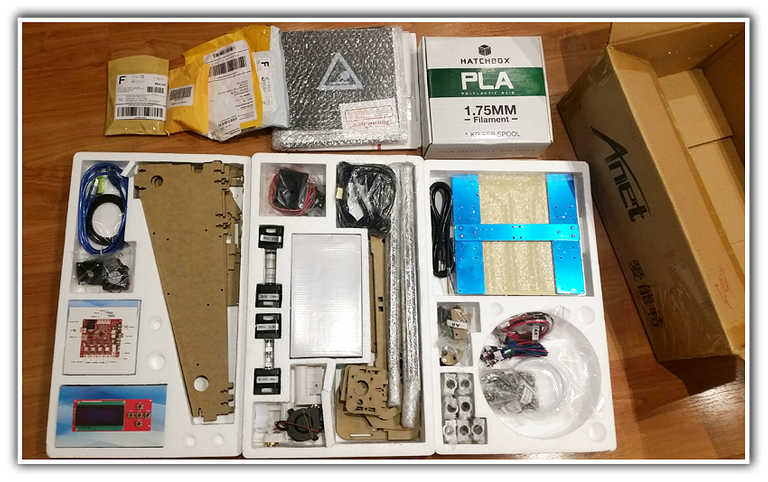

With @themarkymark's guidance, I decided to purchase the Anet A8 from a kit. I wanted the full experience of building a 3D Printer from the ground up so I truly understand how it all works. I ordered the main kit, plus a bunch of extras parts and accessories he mentioned would make my life easier and reduce potential problems in the process.

I figure this knowledge will help me later on in modifying and expanding my systems later in time. Plus, I will have the extra joy of knowing I built it when I successfully print my first part.

Now it's time to turn this...

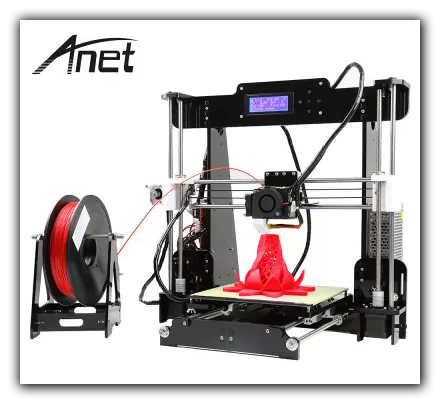

Into this...

I will take some time this weekend to get everything out of the box and ready to build. Then have at it in the next few days. I'm not in a rush, so will just work through it at a normal pace. I will document my build and first test print and share the process in future posts.

Let me know what you think, please leave your comments below.

As always, please upvote this post and follow me if you like my work and want to see more.

If you think others will enjoy this

Please ReSteem it!

Thanks for reading!

Love, love, love this! I have been silly not to have purchased one already! Can't wait to see what you print out! Happy Saturday!

Happy Saturday! Yeah I put it off for too long as well, but I decided to go all in with the challenge. :-)

I always love how organized and planned you are. Good luck with your new toy. When you have conquered this, consider that 3D printing is not just for plastic materials. There are printers that can print composite materials and a growing group that can print metal. The company I work for has used a local tool builder who has two large laser sintering powder bed type that they use to make actual tool details for there large injection molding tool business they run. It's amazing they can go from the printer to the tool. You can weld the printed tool steel details, grind them or anything you would do to a block of tool steel from the foundry.

:-) I appreciate that and am looking forward to the whole experience for sure. In time I will learn more about the different types of printing filaments and expand my capabilities. Thank you for the support.

What is the first thing you will print? Would love to see pics

Not sure on what the first item will be yet, but I was mentioning to others that it will probably come in most useful for printing miscellaneous items around the house and cars. Like a small cover that clips over the webcam on my laptop :-)

Yes custom stuff makes the most sense but you will have to design it properly. Best of luck, will eagerly await the outcome 😀

Wishing you much success with your project! 3D printers are fascinating, and we're really just in their "childhood" stage, as of yet. The idea that you can upscale these to where they can actually "print" a full scale house in a day or so strikes me as having huge potential for the future of humanity.

Thank you. I look forward to the challenges that come with this project - and all the cool things i will eventually be able to print.

True on the large scale printing. I saw a program on printing with concrete to build structures, it was really cool how that technology is advancing.

What are you mainly aiming to print? I'm interested to see an update when you've completed your printer because this is something I might want to do in the future.

Honestly, it will probably come in most useful for printing miscellaneous items around the house and cars. Things where you say "uhg, why does't that have a 'clip or something' to do this or that." So I will see if anyone has created a model for it yet, if not i will do it myself. ;-)

Sounds right handy, and by cars I assume you mean model cars not fully-sized functioning cars.

I’m having a problem where my extruder gets filament goop on it then drops down onto the print ruining it. Is there something simple I’m missing, because I can’t seem to find out how in the world the filament is getting up there.

How long have you been using this particular printer? In certain circumstances, if you've run some more abrasive filament through the system and you're using a brass nozzle, you can get extrusion which occasionally gets caught on a worn edge of the nozzle itself and curls back, beginning to make a glob depending on which direction the head was moving at the time. That can mean that you just need to replace your nozzle, which is a little bit of a pain but definitely within the realm of possibility.

The problem could be completely different, depending on how that group is forming and where, exactly, it's forming from. We might need pictures.

Thank you for jumping in to answer that. :-) I'm sure I will experience all these issues along the way myself as i get started.

My pleasure. 3D printing is still very much a tinkerer's art as much as it has any science, and you have to be willing to get out in front of it and understand that problems can have many sources.

So far I've been extremely lucky with the low cost printer that I chose to be my primary, but I am trying to stay aware of all of the problems that can come up in the course of operations. That is a lot of continuous research and staying on top of things.

I am looking forward to this new adventure ;-) Thankfully @themarkymark has given me some guidance on what to expect so I don't drive myself nuts with the little problems that pop up along the way.

I will definitely share my experience doing this to help others as well.

Amazing.....I should purchase one of these soon

I got the same one month ago, but I didn't managed yet to calibrate it as I would like to or like they print in their videos. I can't manage to have an excellent quality, except when I print at 0.06mm but it takes an eternity. And If I print it at 0.2, 0.4 or 0.6 the piece is to fragile and breaks in slices even if I fill it at 100%. Do you have any advices? I am printing with ABS at 240°C and the plate at 110°

I really like you post! Good job 👏🏻 I

Great, I think it is time to become acquainted with this kind of technology now, just imagine all the things that you would be able to do in the future, I think people won't buy clothes but just print them hah.

Lego for grown ups! Good luck building! :)

This looks like lego in the making haha

Cool man! Lets see what your gonna print!

Good Luck with building your printer. Hope we get some pics to see of the first test prints later on!

This is awesome. Pleases post pictures of the work in progress!