Different types of Power Stations.

The principle used to rotate turbine for generation of electricity is known as prime mover and the different types of prime mover, used for running the turbine, designate the type of power station. Thus, steam generated by heating the water either through burning coal, diesel, nuclear energy, solar energy are the steam power stations, popularly known as thermal, diesel or nuclear, solar power stations etc. The other sources of energy utilized for rotating turbines are wind, geothermal gas, bio gas etc. In case of a hydro electric Power station, the water acts as prime mover to rotate the turbine

and the rotor of generator for production of electricity.

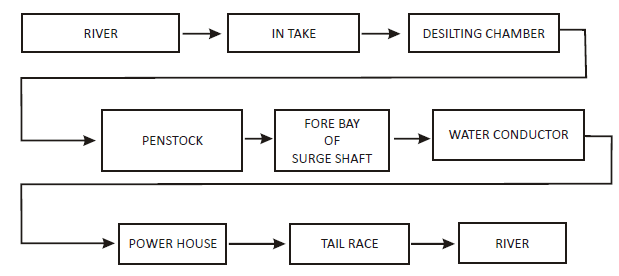

The component structure of a hydro- electric project.

The major component structures of the hydroelectric project are-

- Intake

- Desilting chamber.

- Water conductor.

- Fore bay / surge shaft.

- Pen stock

- Power house

- Tail race.

Intake

The quantity of water (discharge) of the flowing river is diverted beyond the river through construction of barrier across the river, called diversion structure, where in the water will take a turn through a intake structure.

Desilting chamber

The river water carries much silt and sand particles, particularly during monsoon period. Such sand particles need be removed from the water by an arrangement called desilting chamber. Otherwise those silt if allowed to flow, will damage the turbine runner, leading to affect the generation.

Water Conductor

The silt free water is allowed to enter in the water conductor, either in theform of a channel or underground tunnel to carry the discharge to a tank called fore bay tanks or a vertical shaft. The purpose of water conductor is to create the head or the drop (H) as per natural surface for generation of power.

Fore bay or Surge shaft

These are the large concrete tank and the function of which is to control the flow of water during starting of the power house or taking shut-down of the power house. Additionally, it helps the pen stock pipe, leading to power house from damage due to high pressure of water developed during shutdown.

Pen stock

The water from fore bay /surge shaft travels to power house through either over the ground or under the ground, called penstock or pressure shaft. It is made up high boiler quality steel plates to with stand the high pressure of water, running to power house.

Power house

The turbines and the generators are accommodated to produce power inside the power house. The size of the power

house depends on the number of machines required for generation of electricity. The power house may be surface or

underground, mostly depending on availability of land as well as the formation of rocks (geological rocks strata).

Advantage of water power as fuel over thermal, diesel etc.

The natural resources like coal, diesel used for generation of steam has the limitation of availability and other constraint. Water, the main fuel for hydro power, is the never ending natural sources of energy, unlike coal, neither it can be consumed nor it can be converted into anything else and after generation of electricity, it flows along the downstream of the river to irrigate the field, quench the thirst of the cities and support the aquatic or water borne wild

life, like fish etc.

Estimation of water power potential

The two main characteristics or the raw materials of water power are:-

a) Quantity of water

b) Drop of natural terrain through which the water falls.

If the quantity of water, flowing in the river is Q cubic meter per second and the net drop through which the water falls is H, the energy obtained from turbine in kilowatt is Power (P) = 9.8 x Q x H x Efficiency of turbine and generator.

Two major schemes, based on availability of water Basic two schemes of hydro power are:

a) Run of the river scheme.

The availability of water in the river varies during different seasons of the year, i.e. less during summer, winter period and max during monsoon period. The varying discharge utilized for generation of power is the run of the river scheme, where the production of power varies as per availability of water.

b) Storage scheme

Here the major available water during monsoon is stored by creating a large reservoir and the power is generated as per requirement of gird.

FLOW DIAGRAM OF A HYDRO POWER PROJECT SCHEME

Conclusion

Hydro power is our richest renewable and environment friendly resources of energy. The inherent ability for instant starting, stopping and managing load variations helps in conserving fossil fuels, like coal, diesel gas etc. Development of the power station means added advantage of development of remote and backwards regions of the country.

As per latest record the total hydro power potential of our country is assessed to be about 1, 48,700MW in addition to 56 potential pump storage site of assessed installed capacity of 94,000MW. Till now hardly 30% of the total potential has been harnessed for generation of hydro power and thus lot of scopes are remaining pending for the major potential sites like Sikkim, Arunachal Pradesh And Jammu & Kashmir etc.

There are further scopes of developing about 50,000 MW installed capacity of small, mini and micro hydel schemes (capacity up to 25MW). The major schemes are identified in Himalayan region where the fast flowing and perennial streams can easily be exploited.

With the development of latest technology, the hydro power projects are going to dominate over the other conventional projects for the faster construction and utilization of modernized equipment. The highest capacity of hydro power station, commissioned so far globally, is three gorge hydro power projects with an installed capacity 22,500 MW with 34 generators over the river three gorges, in China.