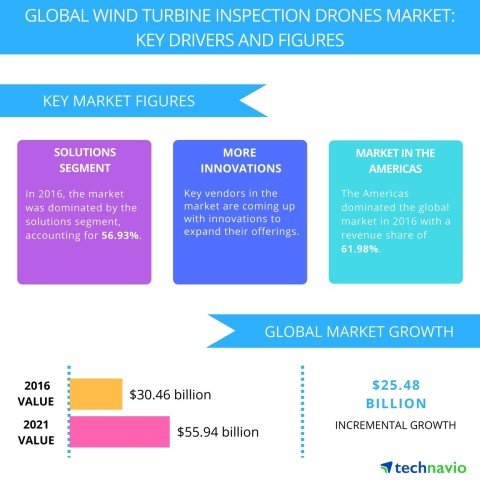

Technavio has published a new report on the global wind turbine inspection drones market from 2017–2021. (Graphic: Business Wire)

May 12, 2017 02:23 PM Eastern Daylight Time

LONDON — (BUSINESS WIRE) — Technavio’s latest market research report on the global wind turbine inspection drones market provides an analysis on the most important trends expected to impact the market outlook from 2017–2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

Global wind turbine inspection drones market is expected to grow at a CAGR of almost 13% over the period 2017–2021.

Tweet this

Raghav Bharadwaj Shivaswamy, a lead analyst from Technavio, specializing in research on robotics sector says, “The global wind turbine inspection drones market is expected to grow at a CAGR of close to 13% consistently over the forecast period. This is because there is increased awareness about the application of these drones for maintenance and detection of defects in wind turbines. Vendors are constantly innovating product designs and technologies, and implementing them in their offerings to introduce products at various price points.”

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

The top three emerging market trends driving the global wind turbine inspection drones market according to Technavio research analysts are:

Technological improvements in hardware

Surge in operational intelligence and data analytics

Increase in adoption of thermal imaging in drones

Technological improvements in hardware

Apart from wind turbine inspection drones, the software solutions required for analysis of data and images acquired are also evolving with time. Vendors are continuously introducing offerings that can improve the functionalities of wind turbine inspection drones. For instance, Pro-Drone, a major startup in the market, has introduced a solution that enables users to customize the control of the drone as per its positional awareness about the blade’s placement. Based on this information, the drone sensors provide information that can help maintain an optimal distance from the turbine’s blade. This ensures minimal intervention from drone operators, and the drone can conduct wind turbine inspections semi-autonomously.

The vendor has also improved its payload capacity to ensure that industrial cameras can be easily carried on these drones to obtain precision. As the market gains traction, more players will emerge with increased emphasis on improving the autonomous nature of wind turbine inspection drones. Such developments can significantly reduce downtimes by carrying out an inspection in about 40 minutes.

Surge in operational intelligence and data analytics

In addition to advances in wind turbine inspection drones, significant improvements are seen in operational intelligence and data analytics software solutions for automation of photo analysis. There are advances to improve real-time data gathering to enhance operational intelligence and ensure the data are available to various expert teams simultaneously for conducting the analysis.

“These solutions also allow the data to be sourced and integrated from a variety of platforms and ensure that the information is standardized. Based on the information, the inspection team and experts can make more informed decisions regarding the operation and maintenance of their wind turbines,” says Raghav.

Increase in adoption of thermal imaging in drones

End-users are investing in improving maintenance and operational services of their wind turbines. Thermal imaging is a technology that is increasingly gaining prominence for predictive maintenance programs for wind turbines. When electrical and mechanical components heat up during technical failures, thermal imaging uses this property to spot temperature increase and uses it to detect wear and tear of turbine parts.

The technology is increasingly being adopted to detect changes in components on a regular basis and in a more precise manner. For instance, Intellisystem Technologies ( info@intellisystem.it )provides thermal imaging cameras, known as ThermalTronix TT1640S-UAV, to inspect electrical and mechanical installations.

Thermal imaging is the only technology that allows you to inspect components and provide condition monitoring on the entire electrical circuit, including connectors and cables

Whether your aim is to perform predictive maintenance inspections on wind turbines or to check the the rotor blades integrity, thermal imaging cameras integrated on a Drone device are the right tool for the job. Intellisystem Technologies offers a wide range of specific thermal imaging cameras (under the Thermaltronix family name) that can be integrated on most common Drones — UAV- UAS, so you can be certain that Intellisystem Technologies has exactly the right camera for your application.

THERMALTRONIX TT1640S-TID-A by Intellisystem Technologies

Thermal Inspection DRONE — UAV — AS Infrared Imaging System. This series of UAV is foldable, easy to carry and to be put into backpack with a foldable frame and convenient to close or open etc. it features with greater load capacity, longer air staying time, perfect power configuration.

FPV: First-Person View with high resolution analogue video transmittering to an RC aircraft, Ground detail can be seen even facing late afternoon sun

IOSD: Highly involved and safe flight experience through collecting and trasmitting real-time flight data which is overlaid with video such as power voltage, flight velocity, height, flight attitude and GPS number, etc, and it supports Double Video Source Input (PAL and NTSC) Real-time monitoring & recording under different circumstances of light Excellent protection design for flight safety Optional data radio & digital image system enables BVR flight and image transmission at radius of 5 miles PTZ augmentation function (pitch/roll axis) efficiently eliminates video jitters Product Features

Advanced Stabilization Controller

9 Multi-Rotor Configurations & Customized Motor Mixer

Intelligent Orientation Control (IOC)

Point of Interest (POI)

Intelligent Landing Gear

Auto Return-to-Home

“Banked Turn” Mode

Cruise Control

ThermalTronix By Intellisystem Technologies

More info about ThermalTronix Solution -> www.intellisystem.it

The data gathered can help in preventing accidents and downtimes.