The manual screen printing ink used generally consists of two types. Namely waterbase inks and solvenbase or plastisol inks.

Each type of ink is closely related to the results to be obtained from the screen printing technique. There are so many types, so for the beginner will be a little confused. But if you are used to it is very easy to recognize it and apply it in sablonan T-shirt will be made. Here is the type and application of some of the ink.

- Ink waterbase :

There are at least five types of waterbase ink that are commonly used.

Rubber ink. This type of ink can be applied to light and dark colored shirts. Its only cover or ride the knitted cloth. If the fabric is stretched, it needs a special rubber paint to be adjusted to the level of flexibility. So that the screen printing can be more durable. This ink is usually used as an underbase whose function is to cover the color of the fabric before any other screen printing color is applied on it. This type of ink there are two, namely rubber white for the dark fabric and rubber color that can be used to mix the various old colors.

Transparent ink. Also known as coating, because it can be used for coatings of screen printing. That way the result looks shiny or more brilliant. Although the shape is transparent, but the content is harder and stronger. Type of ink is very suitable to be applied in the technique of silk screening 4 colors, by applying rubber white as the target.

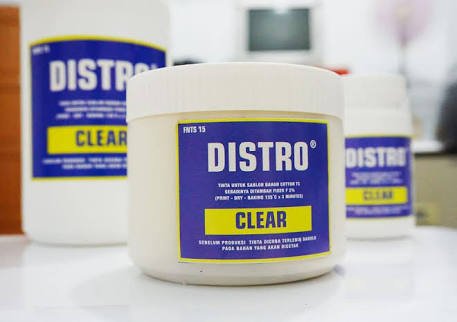

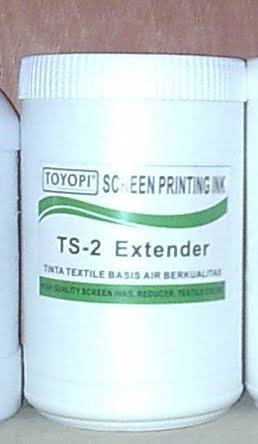

Ink extender. Its nature is also transparent, but only appropriate if applied on white or bright shirts. Its nature is fused and can be absorbed into the material better.

Super White Ink. The function is similar to the rubber ink that consists of color and white. But the nature of the ink is more like an extender ink. Because it is suitable for materials and is transparent. So it can be printed on the surface of the material with a dark color.

Ink arises or puffs. This type of ink is found in both types, both underbase and plastisol. This type of ink requires heating which can cause the ink to pop out as the effect arises. Get perfect results from the application of any manual screen printing ink.

- Solvenbase ink

This type of ink using PVC base material, so it can print dots with very small size. A good drying technique of up to 160 degrees will make the screen printing very strong. A number of these solvenbase paint types are all purpose inks, high opacity inks, athletic plastisol ink, cork base ink, cold and base shimmer ink, high density clear ink and Wilflex Luna Clear. Any application of manual screen printing ink will impact on the results. So apply it to your liking.

code