You never know what you are going to see next on this off grid homestead. One day you may see us hard at work making our own sugar syrup and then later, the GI Joes conquering the cat. You just have to stay alert around here.

The time quickly came for us to harvest our cane sugar and cook it down. The harvest was not as big as last year as some deer decided to romp through our field and bed down among the cane. They destroyed a good portion of the potential harvest this year. But we were still able to harvest and cook down over 3 gallons worth of sugar syrup.

Here is the process.

First the cane has to be cut by hand and then loaded on a trailer. The trailer is unloaded up by our outdoor kitchen. The seed tops are cut off and saved. They will be sold to the public for growing cane and could be used as either chicken feed or dehulled and ground into flour. Cane seed is natural gluten free in case you are wondering.

SQUEEZE THE CANE

The next step is to squeeze the cane to get the juice. We have this 1 HP motor sugar cane juicer from Vietnam from a company called Tubobiz to press our cane into juice.

Everybody gets in on the process. Here is my youngest taking a turn at feeding the cane into the juicer.

My oldest @thehomeschoolkid feeding cane into the juicer.

Even Jaimie is helping to take turns on the juicer. It takes pretty much 2 full days to cut, juice and cook a quarter acre into syrup.

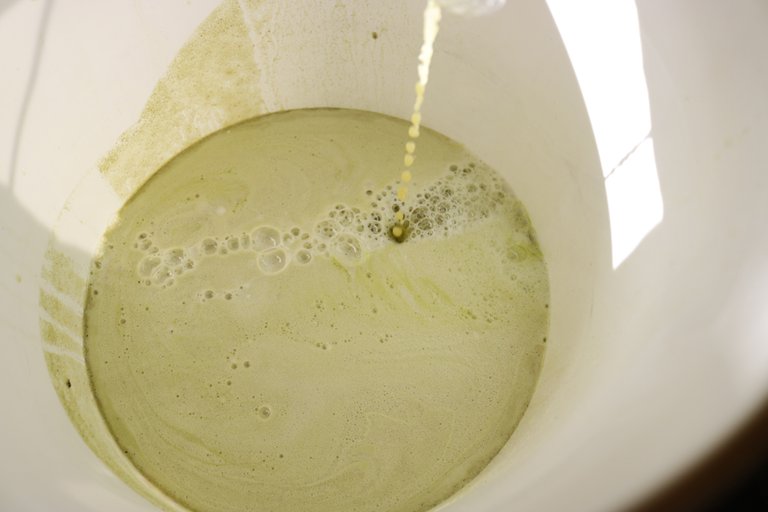

The juice falls from the juicer into a clean food grade bucket that will then be poured into the hot evaporator to cook. This juice is very tasty and healthy. Some people claim that this juice is the best health drink on the planet.

As the juice is collected from the squeezed cane, its poured into the evaporator and the cooking process begins.

The green film that rises to the surface is constantly skimmed off and discarded.

After the cooking is complete, the VERY hot syrup is poured into quart mason jars and turned upside down on a table so the lids will seal permanently. Here is a VIDEO! Sorry, no sound included with this clip.

The jars of yummy sweet syrup are now sitting in our pantry for future baking uses or cooking uses.

Later in the next day, my boys were playing with their action figures and noticed the cat had fallen asleep nearby. Uh-Oh! So the boys set up their action figures around the cat like they had killed the cat and asked me to take pictures.

Boys will be boys.

Visit Us Online: http://AnAmericanHomestead.com

LOL I notice the cat is still in the house.... Sharing to twitter to show a great homestead self sufficiency item!

Growing Cane Sugar is FUN!

It sure looks like it!

I love this! For years we have enjoyed pure cane syrup from an old farmer in the next county. He's a dragline operator by trade, and i met him when he dug my daddy's bluegill pond in 1985. Well, he's getting up there in age now and i dont know how many years he'll be able to cook cane. So I met some Asian ladies at the market where I sell bread, and they grow cane. I traded them bread for baby bok choy (my FAVORITE) and some freshly cut cane. The juice is soooo good! Well, long story short, they offered to give us some cane to grow and told my 14 year old how they grow it (yay home school project!) So we'll be picking that up on Monday. She said she's bringing us the whole cane. This should be interesting!

Love your juicer btw!

That sounds great! Keep me posted!

Interesting process! We would've liked to have came out and helped you all! Anytime you need an extra hand don't hesitate to let us know. It's good learning for us all, and the boys are pretty handy, and always willing :)

No worries, we went ahead and did it because the weather was bearing down and it wouldn't last much longer.

That cat is precious. I used to 'play' a lot with my old cat too. I'm amazed at what it let me do, now that I think back at it.

I've never been a cat person but I like this one.

We used to tap maple trees and boil when we lived in Ohio - best maple syrup we ever had. I'd be interested in trying the cane and making syrup with it.

Fresh maple syrup sounds amazing!

I'm sure that will be some sweet tasting syrup!!! And yeah boys will be boys..I know my brother and I would have done something like that! HAHA

Sounds pretty interesting.

I'd be interested in buying some of those seeds. Can you share how to find where you're offering them?

laid back cat.

Beep! Beep! This humvee will be patrolling by and assisting new veterans, retirees, and military members here on Steem. @shadow3scalpel will help by upvoting posts from a list of members maintained by @chairborne and responding to any questions replied to this comment.

Oh no! Coconut's under attack! I see some older Star Wars figures there too. You sure Coconut doesn't think he's getting a massage? lol

I mentioned to another YT homestead, about thinking of using pressure canners (the big boys) 20 - 41 quart models.

http://www.pressurecooker-outlet.com/Pressure-Canners.htm

Defoliate the stalks, and cut to length to fit (standing up) inside the canner. Snug, but not crammed in. Pressure steam for the needed time, versus all the long cooking and boiling hours to reduce the excess water (and getting out the magnesium chlorophyll green froth from the pressed cane sugar juice). Steaming takes less time, less fuel, less energy for processing and humans.

THEN secondly (not firstly) press the steamed canes from the canner, through a wringer washer versus the high technology and costly mechanical processor. The same wring washer has various levels of crunching and scrunching ... and is easier with steamed and floppy cane, versus scrunching hard cane through the mechanical device. Can process multiple stalks through a wringer, versus the one can method of the machine. And crank down the wringers for greater expression, until you start pressing out the green - that you don't want in the first place - other than separating it out for a magnesium chlorophyll drink - or using as magnesium back onto the garden, for that deep dark chlorophyll of plant foliage. The cane fiber mats can be tossed into the compost (or better yet, along with the chlorophyll be given to the animals to drink and eat the post-pressing sugary canes). Otherwise, toss into the compost for soil fibers and loose soil texture.

Could still use the machine with the steamed canes, and this would be so much faster in pressing out the juice, with second and third pressings with soft steamed canes.

The pressure-steaming kills any bugs/bacteria, so any processing after the steaming is all sterile and clean.

Using multiple canners at the same time, you can process batches in 5-15 minutes (?), press, and then have other canners for doing all the mason jar and lid canning of the pressed product.

Pressure-steaming is KNOWN to keep full nutrition and caloric count, versus cooking and boiling that can reduce health values as much as 50+% (!). Fresh rice is 735 calories per cup, steamed rice is 735 calories. Boiled/cooked rice (and all other such foods) is 235 calories. A lot of wasted food value. Steaming also can be processed up to 15 PSI for 250F, but heat is only needed (like health department restaurant food) to 165F for bacterial sterilization. So any first-steamed sugar cane retains a majority of its amino acids, enzymes, vitamins, minerals, ... and doing the final jar canning (only need a hot water bath) is to JUST get the lids and rings to seal and create the needed vacuum in the jar.

Just saying .... and can do all this outside over a fire, with a metal plate for the canners indirect heating..

And if anybody mentions, what about getting out all that excess water ... as sugar cane is ~12-16% sugar and 63-73% water. Anybody wanting to make syrup or sugar crystals, then pour cane juice into a canner, and steam out the water through the vent, allowing the juice to thicken and sugar ball, without burning or caramelization. Even making molasses and other products. Any making of hard sugar candy, sugar crystals ... pouring onto a cold plate and allowing the syrup to crystallize and then be broken and blendered into sugar crystals is easy. Just steam out the excess water until the desired thickness (heat and timing) is achieved.

Just saying ....

You never cease to amaze me with all you do on the homestead!