Hi steemit how are you guys today? I hope we are all in good health so that we can all continue to work.

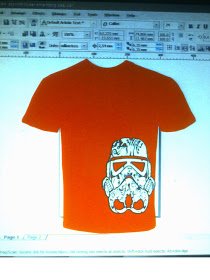

Today I am @boboho is learning to make screen printing t-shirts, I study where friends who do shirt screen printing business, so I will share my experience how to meyblon the right shirt in order to get the best results.

Surely we already know what it is t-shirt screen printing, t-shirt screen printing is making a picture or writing on a T-shirt that makes the shirt is more interesting, so increase the selling value of the shirt. So without long lets look at how to screen shirt is good and right, here are the stages for screen printing t-shirts.

In the printing press or printing there are several steps that must be passed from the business of pre printing, equipment to finishing. After getting to know how to learn to make t-shirt design distro, it's necessary to know the process of how to print screen printing shirts.

The quality of the ingredients greatly determines the final quality of the produce. For example, combed cotton material has a variety of grams, ranging from 20S, 24S and 30S. The bigger the gramation the more light and thin fabric. In places we use cotton combed 20s and 30s. There are several techniques in menggblon shirts, namely manual techniques and digital printing.

Manual shirt screen printing technique, where the process is done by manual print process using screen and rack.

Here is a stage how to learn how to manage t-shirts distros or manual screen shirts.

Setting T-Shirt Design.

Prepare t-shirt design that will be screened before screen printing, then edit t-shirt design into screen printing film or cliche screen printing film ready to be printed screen printing based on their respective colors, in this case t-shirt design must be processed through color rupture or color separation depending on the shirt design can in the form of verbal screen printing or in the form of raster screen printing, you can make a color rupture using coreldraw program or photoshop.

Pre-afdruk stage.

These steps include cleaning and screen preparation. Prepare the necessary screen printing tools such as soap, water, sponge cloth. wash screen printing using water and soap then wipe with sponge cloth. after clean, the screen should be dried by drying it in the sun, this is necessary because before the afdruk screen should be completely clean and dry.

Stage afdruk.

This stage includes drug delivery, screen burning, and drug washing on screen. Prepare tools such as screen, afduk medication, fan / hairdryer, screen tool / ruler, mixed with red and white liquor and then input bit by bit at screen and flatten thinly, then the screen is dried by using a fan or hairdryer. The process of drying this screen should not be exposed to direct sunlight, for it is recommended drying in the room closed / dark.

Stage burning screen.

The next process is to prepare materials such as glass, edited t-shirt design, screen, screen foam, board. Take the Board, put the foam on the board then take the screen we have prepared then put the screen and place the edited image and paste on the screen, before the t-shirt design is taped to the screen first rub with cooking oil, this is done so that the paper on the picture will be translucent. then put glass on the screen.

Then screen with sunlight. in irradiation time required between 15 to 20 seconds (depending on the heat and absence of the sun) because if too long in irradiation, screen pemfilm of the screen will fail or difficult to penetrate. after we screen the screen, then the screen must be washed to clean the former drug. In the washing need a sprayer, usually using a spray to bathe the bird, this tool is used to open the design or images contained on the screen.

Staging stage.

At this stage, the required tools are: screen (which has been filmed), paint, screen printing table (if needed, rake l (shredder), material (t-shirts).) Take screen and then put the cloth to be screened above table, pour paint on the screen sufficiently then gesut using the rack, then be the result of screen printing.

Please note, in addition to good quality t-shirts such as combed, sablon paint also greatly affect the results of screen printing, eg using rubber paint (rubber), there are certain paint that will produce good quality, of course, paint that is not easily broken. some rubber paint that the quality is ugly already seen if touched will look stiff, rough and of course easily broken.

Once the t-shirt is finished, it is finished (final stage).

Stage finishing sablon t-shirts is to use a press machine. Why should the press? ...... because with the press process temperature above 100 degrees will eliminate the water content contained in the paint sablon and will produce a more seamless screen printing quality and will feel smooth if touched. Not all shirt screening products market through this stage.

Thus a short tutorial from me @boboho in making screen printing t-shirts other times I will explain more details making this screen printing. Kind regards from me @boboho and happy weekend.

Nice :) boboho

thank you for your positive response @saimegh

Very cool man.