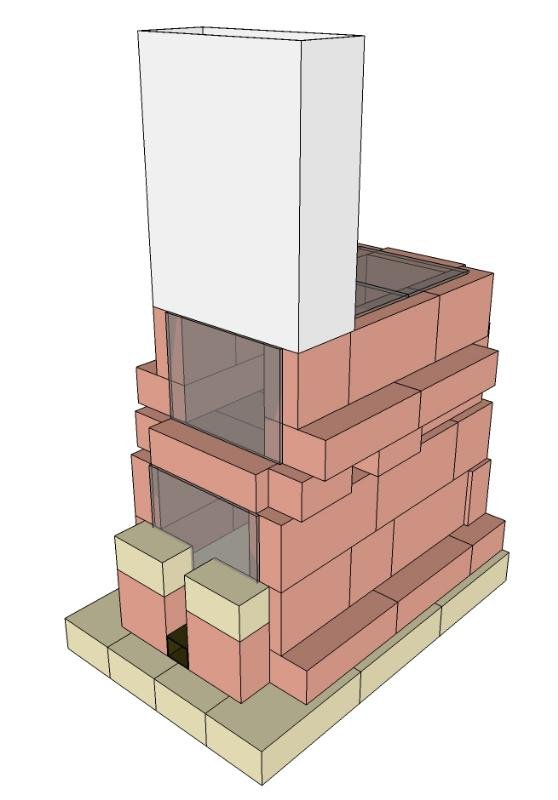

This is the Peter Van Den Berg double shoe box rocket batch style fire box. I thought some might be interested in learning more about it. This is the style I am experimenting with at the moment. Well as I have time lol. (note: these are pics of mock ups Peter has done and not mine.)

There are more actual pics and video of Peters mock ups of this firebox on this thread at permies .com (Link below) Peter is somewhat of a legend in Rocket Mass Heater (RMH) circles. He has also got the attention of the more formal Masonry Mass heater crowd with his batch fire box. Including me, I have always leaned more toward the Masonry heater because I am a retired mason and the brick or stone work is not intimidating to me like it is to people who have not done masonry work before. So they tend to gravitate to the RMH which is often made with cob/adobe and cheap or free recycled materials.

https://permies.com/t/71823/batch-core-riser

A masonry heater can also be made with those materials and they have been but tend to be a bit more complicated and require more skill. Which is another reason people gravitate to the RMH. One of the things that I did not like about an RMH is the small feed tube so even though the mass stores the heat you still had to feed the tube for however long it took to heat the mass.

With a more conventional Masonry Heater you build one fire and it heats the house for a day or more depending on the size and style of heater. Many people light a 30 minute to 1 hour fire in the morning and before going to bed and that's it. That appealed to me more.

Now comes Peter Van Den Berg and he may have solved this difference between the two type heaters. He gets the rocket effect in the firebox that mixes the gasses really well for a super clean burn but one fire does the trick instead of a constant feed over 2-4 hours depending on the heater.

One of the other things I did not like about an RMH is the 55 gallon barrel. Maybe it's just my masonry background. However its just ugly to me lol. One advantage it has is that it acts a heat exchanger and will heat the room faster since metal does not store the heat like masonry. However we're back to my first objection. Since you lose heat through the barrel to the room it takes longer to heat up the mass so a longer fire is required. Although your not really losing heat as it's heating the room.

Some folks build a masonry or adobe heat exchanger with the RMH for these reasons and it acts like a masonry heater so problem solved. I do like the idea of a metal heat exchanger as a sort of hybrid so if you're gone and come back and need to heat the room quick it works. I have thought of experimenting with a wood stove connected to the same chimney for this purpose and maybe you get the best of both worlds. When you need quick heat you light the wood stove and it heats the room fast while heating the mass too. When the room is warm you can shut it off close the bypass and fire the mass heater. That way when you have the mass heater running you don't have to have a longer fire because of heat loss through the barrel and potentially over heating the room.

I was thinking also a nice cast iron heat exchanger that looks nicer, kind of like some wood stoves or a nice ceramic or tiled one would look much better... Anything but a 55 gallon drum LOL. Although Paul Wheaton at permies.com has a nice stainless steel 55 gallon drum that doesn't look bad. Maybe a copper or brass one would look nice too. However now were getting into more expenses usually.

Bottom line is; it boils down to finances resources and personal preference. Some of the low cost RMH cob/adobe heaters look quite nice...so don't let my biases sway you.

This post has been resteemed from MSP3K courtesy of @buckydurddle from the Minnow Support Project ( @minnowsupport ).

Bots Information:

Join the P.A.L. Discord | Check out MSPSteem | Listen to MSP-Waves

Very interesting! We have been considering going to a pellet stove, we are getting tired of splitting wood for our heat. Then we started seeing Wheaton's new videos about the improvements to the RMH. I don't really mind the barrel, I just want to be warm and last year we burned almost 8 cord of wood in this drafty old barn. It is much last drafty after our summer project, but still... the idea of cutting that down by 3/4 is very, very appealing. And to have a prettier option is good, I do LIKE pretty things... lol!

Remember you have to buy pellets....lol. Yeah I see an RMH in your future...

We were not throwing the old woodstove away, just putting it in the barn!

Well I would suggest an RMH. You guys are capable. Get Iantos book if you dont have it and just go for it in the spring. They actually use a tenth the wood of a wood stove. Plant some willows and after 4 or five years cut them down and they will regrow good coppice wood every year for fire wood no splitting required. You could probably do it in a couple days for cheap if you use cob and a 55 gallon drum etc.

We are looking at doing this IN the house, so we are probably going to spend a little more than bare minimum this time. The old RMH is still set up waiting for us to decide what to build around it. The hoop collapsed last year, so we have a couple fairly major projects on the books come spring!