Bienvenidos, estimados lectores a este nuevo post.

proceso de extracción de granos de cacao de su cáscara.

proceso de extracción de granos de cacao de su cáscara.

Cajón de madera (caoba) para fermentar el cacao. Sin recubrimiento ni curado y armado sin clavos (parte inferior) para evitar la interacción con componentes que afecten el sabor del cacao una vez fermentado

Cajón de madera (caoba) para fermentar el cacao. Sin recubrimiento ni curado y armado sin clavos (parte inferior) para evitar la interacción con componentes que afecten el sabor del cacao una vez fermentado

grano de cacao acriollado, se caracteriza por su coloración pálida

grano de cacao acriollado, se caracteriza por su coloración pálida

grano de cacao trinitario, reconocible por sus cotiledones altamente coloreados gracias a los taninos, los cuales también aportan el sabor amargo e intenso característico de este tipo de cacao

grano de cacao trinitario, reconocible por sus cotiledones altamente coloreados gracias a los taninos, los cuales también aportan el sabor amargo e intenso característico de este tipo de cacao

Grano de cacao después de haber sido fermentado, secado en un horno eléctrico y descascarillado

Grano de cacao después de haber sido fermentado, secado en un horno eléctrico y descascarillado

Grano de cacao después de haber sido fermentado, secado en un horno eléctrico y descascarillado. Este lo estrujé con las manos para mostrarles como queda su interior

Grano de cacao después de haber sido fermentado, secado en un horno eléctrico y descascarillado. Este lo estrujé con las manos para mostrarles como queda su interior

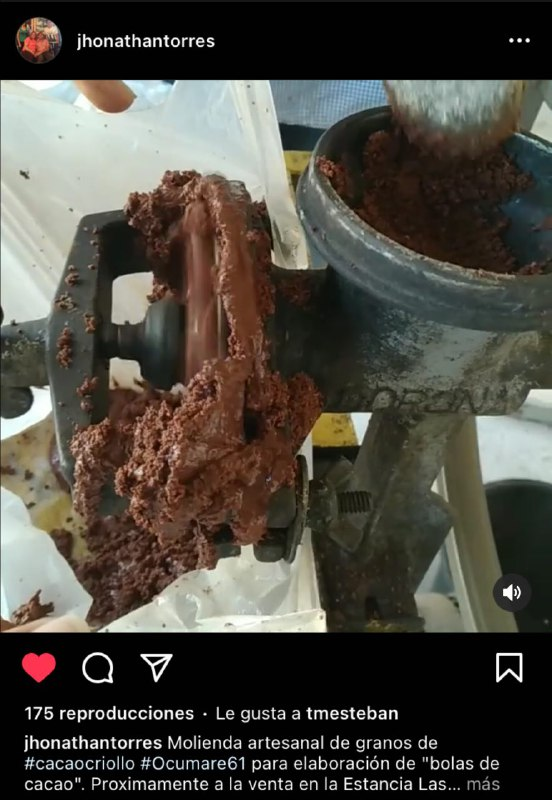

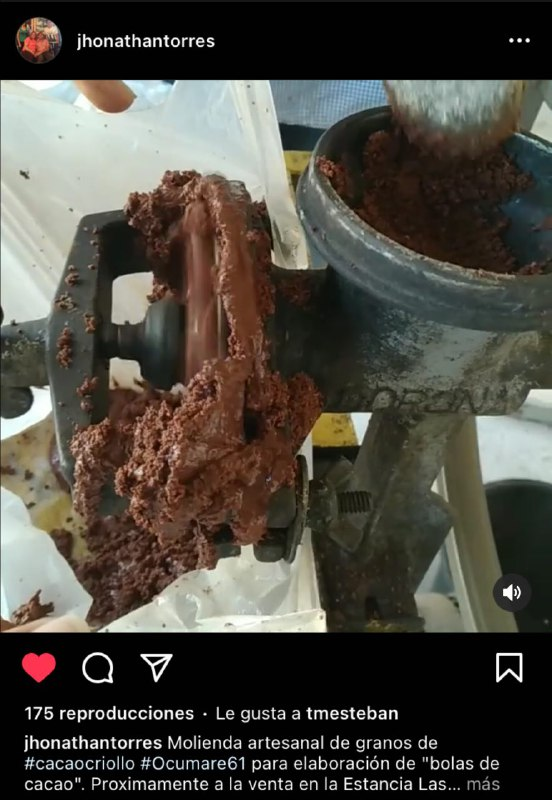

Imagen tomada de la cuenta de Instagram del Prof. Dr. Jhonathan Torres (@jhonathantorres) es una captura de pantalla de un video grabado por él.

Imagen tomada de la cuenta de Instagram del Prof. Dr. Jhonathan Torres (@jhonathantorres) es una captura de pantalla de un video grabado por él.

Nos seguimos leyendo.

Referencias:

-https://powerexplosive.com/beneficios-del-cacao/

-De Rojas J. 1987. La moneda indígena de Mexico. Universidad complitense, Madrid.

Welcome, dear readers, to this new post.

In this article we will learn how chocolate is prepared and in what other ways the fruit can be used in general, as well as the way in which our American ancestors used it. We can also see photographs of two types of almentra that I offered in my first post on cocoa to see how they look, as well as a bean already processed and ready for grinding.

It is recorded that cocoa was highly valued in pre-Hispanic Mexico, not only served as food in different preparations but also as currency in its lower quality varieties, and even after colonization it was used as a representation of value due to the lack of cash of the Spanish empire in the colonies. From this great interest of the Mexica for cocoa derives its scientific name of 'food of the gods' Theobroma cacao, in Latin.

The Indians prepared cocoa by fermenting its seeds, as we do today, then mixed it with hot water to make drinks or pulverized it and consumed it as powder in culinary preparations. Such ways of preparing it were surely learned from the South American Indians, from whom the Mexica obtained cocoa, however, there is little record of the events of those tribes due to their lack of virtue to capture their experiences in some way for posterity.

Fermenting cocoa beans results in an enhancement of their aromas and flavors as well as a reduction in their characteristic bitter taste, which makes the seed more attractive. This way of processing may have been discovered by the natives because it is very common for birds to penetrate the ripe cocoa pods with their beaks in order to take advantage of the pulp that covers the beans, and since they are unprotected, they begin to ferment inside the shell, which is why the pleasant aromas can be perceived when they are harvested.

process of extracting cocoa beans from their shells.

process of extracting cocoa beans from their shells.

Wooden crate (mahogany) to ferment cocoa. Uncoated and uncured and assembled without nails (lower part) to avoid interaction with components that affect the flavor of the cocoa once fermented.

Wooden crate (mahogany) to ferment cocoa. Uncoated and uncured and assembled without nails (lower part) to avoid interaction with components that affect the flavor of the cocoa once fermented.

Regarding the fermentation of cocoa, this can also be carried out inside sacks or any structure that adjusts in volume to the beans to be fermented and that is made with materials that do not react or give off odor and that are harmless to the fermentation process. For this purpose, banana leaves, banana or heliconias are also used to wrap the grains inside the container.

The fermentation time of the cocoa will be determined by the experience of the cocoa/chocolate maker. There are references of this according to the type of cocoa to ferment, in general for criollo cocoa beans are usually left to ferment for about 3 days, while the Alto-Amazonian and Trinidadian cocoa beans ferment for 5 days or more.

The cocoa bean is characterized by its pale coloration, which is

The cocoa bean is characterized by its pale coloration, which is

trinitario cocoa bean, recognizable by its highly colored cotyledons thanks to the tannins, which also provide the bitter and intense flavor characteristic of this type of cocoa.

trinitario cocoa bean, recognizable by its highly colored cotyledons thanks to the tannins, which also provide the bitter and intense flavor characteristic of this type of cocoa.

After fermentation, the cocoa is left to dry, at the artisanal level this is a work that is done exclusively in the sun and is a job that involves spreading the beans, move them every so often and pick them up again at dusk, repeating this process until the bean is completely dry. At the industrial level, sun drying is brief or non-existent, most of the process is carried out with the help of ovens of various types.

Cocoa beans after being fermented, dried in an electric oven and shelled.

Cocoa beans after being fermented, dried in an electric oven and shelled.

Cocoa bean after being fermented, dried in an electric oven and shelled. I squeezed it with my hands to show you how the inside looks like.

Cocoa bean after being fermented, dried in an electric oven and shelled. I squeezed it with my hands to show you how the inside looks like.

Once the cocoa beans are fermented, dried and shelled, they are then ground, below is a screenshot of a video posted on Instagram by my thesis tutor, Prof. Dr. Jhonathan Torres, where a process of grinding cocoa beans can be observed.

Image taken from the Instagram account of Prof. Dr. Jhonathan Torres (@jhonathantorres) is a screenshot of a video he recorded.

Image taken from the Instagram account of Prof. Dr. Jhonathan Torres (@jhonathantorres) is a screenshot of a video he recorded.

We can detail in the image as the result of grinding is a shiny paste that represents moisture and could cause contrast since in the photograph of the dry cocoa bean is observed without moisture and its texture is even brittle and powdery once broken, however, to grind them finely, the beans release their fats and is what makes a paste is formed, which is known (at least in Venezuela) as cocoa liquor.

Perhaps at this point you are wondering then, how is cocoa powder obtained? Well, once the cocoa liquor is obtained, a pressing process is carried out with materials of a very fine porosity to extract the fat, resulting in cocoa powder separated from its lipids. It is this powder that we commonly find in commercial establishments.

Then, finally, the elaboration of chocolate uses a percentage of cocoa powder, a percentage of its fat added separately and different percentages of ingredients such as sugar, vanilla, milk, etc., the manufacturers of fine chocolates use the least amount of products other than cocoa in their recipes, which merits the use of very fine cocoa clones that provide soft and harmonious flavors and aromas to the palate because they are to be tasted as chocolates, that is, without accompaniments. As well the tempering technique to result in a joint sensation of flavor and texture extraordinaries. This technique consists of heating the chocolate mixture in a bain-marie but at a temperature below boiling and then gradually reducing it. Temperatures, times and exact details of this process vary according to each manufacturer. Chocolatiers also make combinations of the powder of different clones to reach particular flavors (You can expand this information in my first thematic post).

In the case of the cocoa plantation where I worked, about 20% of the total harvested (by weight) is used in baba (cocoa beans covered by the pulp) and of this in turn, less than 50% is usable once dried and shelled resulting in a yield of less than 10% in total from the harvest.

Due to the above we conclude then why fine chocolates are so treasured; and is that it is extremely difficult to meet all the conditions to create a chocolate with a high percentage of cocoa that at the same time is pleasant to the naked palate, this results in a product that provides aromas and unique sensations, besides inducing the body to the release of hormones such as endorphin, which generate feelings of pleasure and also provide us with antioxidants and various minerals.

Thus we reached the end of this little tour, where we could learn about the origins of cocoa consumption, the characteristics of the almond of two of its main types and how is the general process of elaboration, which is why it is such a coveted product around the world.

Thank you for joining me this opportunity, I hope the information has been of benefit to you and you liked it.

We will keep reading. References: -https://powerexplosive.com/beneficios-del-cacao/ -De Rojas J. 1987. La moneda indígena de Mexico. Universidad complitense, Madrid. -https://books.google.co.ve/books?hl=es&lr=&id=pDcblMape5IC&oi=fnd&pg=PA7&dq=preparaci%C3%B3n+del+chocolate&ots=RRKZM84QDr&sig=sUtvIOMb4Jsyxma0qLxI5ZbLtUs&redir_esc=y#v=onepage&q=preparaciaci%C3%B3n%20del%20chocolate&f=false

Congratulations @simonaris! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s):

Your next payout target is 50 HP.

The unit is Hive Power equivalent because your rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Check out the last post from @hivebuzz:

Support the HiveBuzz project. Vote for our proposal!