Hey folks @cryptokraze here and today I will share the simplest procedure for producing butter. It is a very common dish in many countries including the Indo-Pak, it is done at every home.

Cream Separation

Butter can be made from the milk of camels, buffaloes, mares and goats. The cream is separated from the milk. The cream can be supplied by liquid dairy milk products or by butter manufacturers from whole milk. The cream must be sweet (pH greater than 6.6), unoxidized, odourless. The cream is pasteurized at 95 ° C or higher to kill harmful microorganisms.

Ripening

Sometimes cultures are added to ferment lactose to lactic acid, and the cultured butter has desirable taste and aroma characteristics.

Ageing

The cream is stored at very cool temperatures to become crystallize the butterfat globules, guaranteeing appropriate churning and texture of the butter. As a rule, ageing takes 12 - 15 hours. From the ageing tank, the cream is pumped to the churn or continuous butter maker via a plate heat exchanger which brings it to the requisite temperature.

Churning

The cream stirs and eventually forms the granules of butter, which grow and coagulate. In the end, there are two products: the semi-solid butter and the remaining liquid, which is called buttermilk.

Draining of Buttermilk

Therefore, the cream is divided into two parts: butter and buttermilk. In conventional mixing, when the grains of butter reaches a certain size, the machine stops and the buttermilk is unloaded. With continuous butter producers, buttermilk drainage is also ongoing.

Salting & Working

Salt is used to enhance flavour and shelf life because it acts as a preservative. In addition, butter is kneaded to increase its consistency.

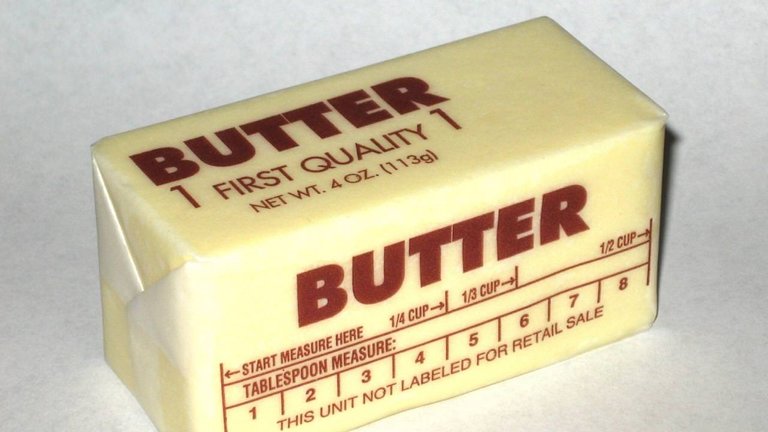

Packing & Storage

The butter is finally formed, then wrapped in wax paper and stored in a cool place. When cooled, the fat crystallizes and the butter becomes hard.

Butter is great, especially fresh butter from quality raw milk. Full of nutrition and delicious. Thanks for sharing the process on butter making!

This is educative

Nice

https://steemit.com/food/@mahfuz42/good-news-eat-garlic-can-save-your-life

I would want you to read this blog:

https://steemit.com/encourage/@eglorch/don-t-get-frustrated

Hey cryptokraze how r u I like ur Post to much dear pls Vote me nad follow me pls I have already given u vote

I am Nazmul naheed from Bangladesh,

It's not just India and Pakistan but it's a huge demand in our country. This work is very good. Thanks to you for sharing it with us.Your all picture is really amazing.i always with you.i already resteem & upvote your post.

your post made me Hungry :p

wow butter so delicious , its a very heakthy food , good information , keep it up

Your post is always different i follow your blog everytime , your post is so helpful . I always inspire of your post on my steem work . Thank you for sharing @cryptokraze

Follow my blog @powerupme

Hm... thanks :)

I didn't have any idea how it is made

Grass Feds the best!👍

That looks exceptionally intriguing. A debt of gratitude is in order for sharing The Process of Butter Manufacturing. I hope you are doing well and have a wonderful weekend!

Can we make it home with the instruments we have. Will it be enough tasty?

Nice

https://steemit.com/food/@mahfuz42/good-news-eat-garlic-can-save-your-life

Very informative. Nice one.

I love butter! I used to make it at home:) it was so delicious!