The Clear Purpose of the Fermentation Spirit Defeats a Myriad of Challenges

What does fermentation entrepreneurs make different from other businesses? They are well aware of their Why. Every operation knows their What. According to Simon Sinek, some know their How and only the successful bunch know their Why.

What do fermentation entrepreneurs have in common with the rest of the business world? They know their What, since obviously every business owner knows what product or service they bring to the table. And just like every other operation on our planet, fermentation operators need to figure out their big How, and all the small ones in between.

Vision Collision

When establishing their How’s, all fermentation entrepreneurs find themselves pondering on the challenges of time, money and know-how. This is no different from the rest of the business world. However, “fermentation” is one part of the dream, “entrepreneur” the other - and sometimes those two don’t get along and put fermentation enthusiasts (= fermento) in front of their hardest decisions. The How’s of fermentation ventures are more likely to collide with their vision, since their Why’s are deeply engrained in lifestyle-related beliefs.

- The pursuit of self-sufficiency along with independence from the food industry,

- a deeply engrained passion for experimenting as well as

- the readiness for taking time to see real quality as the final product:

these are only some of the many strong visions fermentos are driven by.

“How do I not lose the fun and personal connection with my ferments while pursuing a sustainable business?”

“How do I keep experimenting with the very nature of what fermentation is, while I need to offer a consistent product to grow a profitable business?”

As much as ingenuity and curiosity spark the fire of trying out fermentation in first place, many fermentation operations have proven that this inventiveness, diligence and creativity rooted in the very essence of fermentation - a natural phenomenon, a process calling for care, practice and time - can be challenging to keep when adding the “entrepreneur" to the “fermentation”.

“There is a certain amount of capitalism required for a sustainable business within this society and it is difficult sometimes to know what the best decision is.”

Sash Sunday of OlyKraut in Olympia, Washington

Success = fermentation + entrepreneurship

Success - fermentation = entrepreneurshipSuccess - entrepreneurship = fermentation—> These equations are wrong, and they are not the way to go. ‘Smart Fermentreneurship’

And it is the same inventiveness, diligence and creativity, recent fermentation businesses have proven with, that there’s no need to drop the original attraction of fermenting practices on the way. When applying the same principle to the business side of things, they actually can go hand in hand with each other. This way, ‘smart fermentreneurship’ is born, ready to inspire not only other fermentation operations, but outgrowing itself to inspire action, even in businesses beyond the realm of fermentation.

Fermento Hacks

The success formula rather looks more like this

(corrections from maths geniuses welcome):Success = (fermentation + entrepreneurship) x X (=fermentation spirit)

When fermentation operators found themselves facing challenges with authorities devoid of fermentation knowledge, they simply stroke up a conversation with them. After all, communication is key for building trust. When a community of teens with life-threatening illnesses produced a ferment, it became so popular, that they sold it at local supermarkets. The money found its way back to the original purpose.

Find out how a bunch of smart fermentation entrepreneurs overcame the shared challenges of know-how, money, time, quality and last, but definitely not least: vision - the very reason why they exist and do what they do.

Know-How

How do I best get started?

Every fermentation operation, be it a small one or an upscaling business pursuing growth, needs to start at one point - but which steps to take first? Experienced fermentation entrepreneurs like cheesemaker Nathan Arnold from Sequatchie Cove Creamery are sharing their valuable hands-on experiences with you.

- Product quality first: Focus on quality and get really good at what you do. Take your time and experiment through trial-and-error, what works best. This goes for materials, techniques, timing, temperature, location and many more. Research, read, repeat.

“At least go through the heat of the summer and the cold of the winter before trying to get into a fermenting venture.” - Nathan and Emily Pujol

But, we found that brined products-particularly cucumber pickles-were exceedingly difficult to scale up, with regard to salt concentration. (…) We found the optimal salt concentration only by trial-and-error.” - Dan Rosenberg

2. Know your product, process, materials: Quality won’t stop with the product. As you know the process of fermentation perfectly, you are aware how sensitive fermented products can be: temperatures, humidity, timing, seasons, any changes from ingredients to slight alterations in their environment or access to nutrients can highly influence the outcome. Organism and enzymes activity change with the slightest details: microbial life is alive, meaning it’s subject to vicissitude. That means, when you up-scale your fermentation business, the ratios of ingredients may vary and product consistency may be challenging. Of course, your equipment plays a major role as well. The materials you use for fermenting are a chemical compound and have to be chosen carefully since they have an effect on your product. And lastly when the products leaves you, consider shipping time, storage, and especially packaging. As more eco-friendly packaging drives cost, collecting deposits on reusable containers to encourage buyers to return them for reuse are an option. Another solution is considering new technologies such as corn-derived plastics etc.

“We locate shelves and cupboards in strategic spots all over the house to avoid direct sunlight or extreme hot or cold spots throughout the seasons. When the seasons change, we have to rearrange our house to keep it optimal.” - Nathan and Emily Pujol who ship cultures all across the US - home-based culture-propagating operation

“It is a challenge to keep the cultures in their most fresh and vibrant state, since they will not be under the same conditions as they used to. (…) We must also be aware of where they are shipping to, how long it will take, and the general temperature along the way.” Nathan and Emily Pujol

3. Start small: Grow organically, naturally and slowly. Keep your day job and invest only, as the demand grows. Can you operate from home? Do you meet the regulations for a legitimate business?

“One way to minimize both start-up expenses and regulatory scrutiny is to start in a shared kitchen facility. (...)

We made the decision to launch our business in a shared use incubator kitchen. This was a great decision for us because the burden of maintaining and building our own kitchen was lifted.” - Jennifer de Marco of Fab Ferments in Cincinnati, Ohio

4. As an entrepreneur you need a (business) plan. This includes knowing the market:

“Are you meeting an unfilled need or are you creating a demand from a new innovation?” - 'The Art of Fermentation' by Sandor Ellix Katz

And there are the rules: that is the huge apparatus of codes, regulations, and meeting requirements waiting for you: paperwork en masse. You will have to get informed, consider that it may take time, educate authorities and especially communicate with them by building trust. There are people behind the stamps.

“But we learned early on that this challenge can generally be overcome by communicating what we know about the process in a confident tone that makes regulators trust that we know what we are doing." Anonymous, 'The Art of Fermentation'

Many who put their stamp on your paper, may tend to go for the “Rejected” one - just because they are not familiar with what fermentation is and what it involves. A “no” is faster than a “maybe” involving research.

“Figure out the regulations for your area first.” - April McGreger

Who is your target group? Which persona would buy from you and at what price? These are questions you might want to ask.

5. The good news is: there’s a lot of support out there. ‘The Art of Fermentation’ by Sandor Katz, his community, and of course those who have done it before you. Choose a role model as a mentor, or find a consultant and share. If they are local and see you as competitor, then go global. Communicate, exchange share and take and give! Get involved in Facebook group, stay posted on what the community is up to from magazines like Cured.

The Know-How of Others

Making sure your product is enjoy the way it’s supposed to educate your clients as much as you can about the process and how they need to keep it to enjoy best. Do the same with authorities and help building the foundation for many more ferment operations to come in future. Isn’t it exciting to walk a path that by far has not been ausgelaufen! and you are part of it.

“Make sure folks who buy your product know that you have to keep it refrigerated because it’s not a pasteurized shelf-stable poduct.” - Erin Bullock

Money

“Find the closest college/university that has a food science program. Each of these schools usually has an industry-related extension program that is usually funded by grants to help support start-up businesses.” - Mark Olenick of Lititz Pickle Company in Pennsylvania

As you start small, work smart: Invest only if your demand grows and if you got your investments covered. If you can’t afford it, stretch resources, be inventive and create your own solution.

“To dry the beans, one of the most laborious parts of the process, he created a simple device in which to place the drained pot of beans. The pot sits at an angle and rotates, so the beans continually get turned over, as a fan blows air right onto them. They make the tempeh in plastic bags with holes poked in them. You can do this by hand with a pin or a fork if you are doing just a few, but hundreds? Jose created an ingenious roller with nails poking out to be a hole puncher.” Sandor Ellix Katz on The Tempeh Shop Gainesville Florida, 'The Art of Fermentation'

After all ingenuity is one reason why fermentation fascinates you: keep experimenting.

“After 7 years of working out of a community kitchen, we finally purchased our own building last year and turned it into pur very own pickle factory, which has been working out very well.” Dan Rosenberg of Real Pickles in Greenfield, Massachusetts

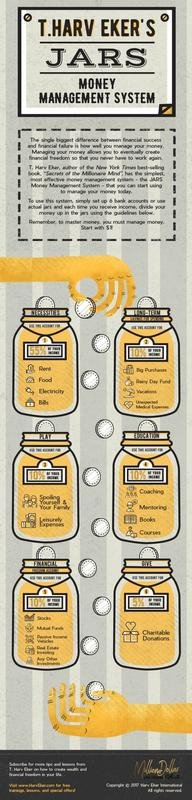

Know the pricing of your competition, and think ahead - your material, your packaging, ingredients, location, storage, marketing from A-Z. Imagine the whole way from the perspective of your customer. Get opinions fromfriends. Take care of licensing and insurance. Make a shared incubator kitchen your co-working space. Check if you want/need a trademark registration. Always remember what you are in it for: is it a niche you want to cater to? Are you just generating a little money on the side or are you aiming at the big pot of growth? Or maybe you are just incorporating fermentation into your bigger business model? In any case, for budgeting check out this (maybe) fermentation-inspired model.

“Figure out where you will source your produce. Know your market/competition/-prices, demand, etc. I am a huge proponent of direct sale, and farmer’s markets have been a great place to start and grow my business.” - April McGreger

Of course, your learning curve will also include marketing: How much would you buy your product for? Is word-of mouth marketing enough? Do you sell locally only? These are some of the questions you will ask yourself.

Time

The word “entrepreneur” originally means “to undertake”. And yes, your fermentation venture is an undertaking. For it not to end up with the “undertaker”, time is your best friend and one if the dimensions you need to think in. Things in your control will take time: education, research, production etc., and things out of your control as well: regulation, licensing, up-scaling your business, test-and-trial.

“One season in year two, he points toward year five as his goal for achieving consistency, marketing success, and profitability.” - Sandor Ellix Katz on the Farmstead Creamery Challenges (Nathan Arnold from a cheesemaking operation at Sequatchie Cove Creamery in Sequatchie)

Quality

And it is also Nathan Arnold who faced a harsh wind in his beginnings. Sometimes your know-how is limited, your consistency is failing, your up-scaling gets complicated and your equipment can only go that far. When Nathan Arnold’s cheese sample didn’t meet the regulations, it took investigation, patience and support from someone else. A whole herd of cows was culled - the cows where the milk for his cheese came from - as an organic farm cannot use antibiotics on their cattle. The cows had been infected by S. aureus.

But he didn’t give up: frequent testing, documenting, help of a French cheesemaking consultant and a voluntary HACCP plan (Hazard Analysis and Critical Control Point Plan by the Food and Drug Administration - FDA) solved his initial big challenge.

Vision

Many fermentation enthusiasts are driven by ideals such as independence, sustainability and curiosity. In many cases, these are in stark contrast to the “entrepreneur” part of every fermentation entrepreneur: capitalism, business models and marketing goals make you worry that you may need to compromise on some essential values, or that what you do may backfire and defeat the very purpose of your venture. You don’t want the boomerang to hit.

“Balancing a for-profit business with working with food has certainly been my biggest challenge.”- Sash Sunday OlyKraut in Olympia, Washington

In this case, carefully consider every decision and its consequences. For many fermentation producers the personal connection with the final product as well as the joy during the process matters extremely. Then it is important to know when it’s time to find your “Why-not”. Giving up your values should never be an option.

“For us that would mean a part-time employee for whom we’ll need an ADA compliant bathroom, a changing room and a break room plus a fully equipped laboratory. Between salary, workers comp, testing in-house and microbiological testing by a contract lab, we’ll need to budget $ 50,000/year. We produce 5,000 lbs of cheese per year. This is why I think that to stay in business a cheese maker must produce at least 50,000 to 100,000 lbs per year.” - Pascal and Eric, goat-farming and cheesemaking partners from California

When regulations are just too impractical for your small fermentation venture, when the paperwork takes more time than your actual fermentation experiments: then you may want to consider if your Why still is strong enough. As a fermentation aficionado you don’t want to lose your enthusiasm on your journey. If you are uncertain, just ask around. Get different opinions, ask your own intuition and then follow suit: brave fermentation entrepreneurs have already demonstrated how it’s done: break down the task at hand into pieces just like bacteria break down sugar, make your decision, act upon it and enjoy the transformation.

All Roads Lead to Rome

Fermentation entrepreneurs are equipped with a spirit of curiosity, which is also the original idea of entrepreneur: to act upon an idea. Because of the nature of a fermentation operator’s vision or Why, the How’s no matter how challenging often are just a stone throw away. When it comes to difficult decisions, entrepreneurship has worked extremely well with fermentation: Fermentation entrepreneurs have shown great leadership that inspires action.

The above examples have proven, how things can made happen in the most creative ways. And some also have shown, when there is a valid reason to give up on a fermentation operation - when it’s simply not feasible. Fermentation entrepreneurs usually aim for bringing our food back home while our wines, cheese and pickles currently come from far away places. One thing is certain: the above pioneers know how to hit a home run, but they can also trust their fermentation spirit when it makes sense to just enjoy watching. After all, fermentation stands for transformation: and this transformation can be just as individual as each batch of ferments.