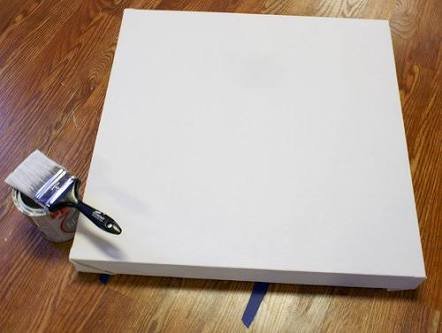

Hello steemians. Below there is a canvas picture. What do you think about canvas?

.jpeg)

Surely what you have in mind is painting. Yes I like that too. The first time that came to my mind after hearing the canvas paper was painting. Media for painting. Have you ever imagined that canvas can be used to build channel construction? Surely you laugh if you listen to it. But this is true. What canvas is meant to be? Not like the canvas in the picture above. It's a different canvas. Here's the explanation so you are not confused.

Casting techniques using concrete is the most common way used when contractors build ditches, drains or ditches and culverts, including when they are about to cover the steep ground.

However, the use of concrete can not guarantee the channel last long and not easily cracked. Cement concrete can not withstand extreme weather, so quickly broken.

Another problem, the use of concrete is troublesome if the project location is in a remote area, the transport infrastructure is poor. Because the concrete must be used in a dilute form. Freight to the site requires special vehicles, such as a mixer truck. Another option is to build a mixer plant at the work site. If transportation infrastructure is poor, then work location is difficult to access.

Preventing the occurrence of hassles in the use of concrete, now comes a new solution called Concrete Canvas (CC). Unlike concrete in the form of bulk materials and must be transported by truck mixer to the work site or can also directly build a mixer plant on site, Concrete Canvas is the result of new innovations that are distributed directly to the site in the form of finished goods that the application is very simple.

.jpeg)

Definition

Concrete Canvas is a flexible fabric fiber impregnated with concrete that hardened when doused with water to form a thin thin concrete layer, waterproof and flame retardant. Concrete Canvas allows the manufacture of concrete without the use of mixer plant or concrete mixer. Because it is in the form of finished goods (rolls), Concrete Canvas can be directly stretched, then doused with water. In just about two hours, this material will harden like a concrete and ready to function.

Concrete Canvas consists of a three dimensional fiber arrangement containing a specially formulated dry concrete mixture. The use of PVC (polymer of vinyl chloride) on one surface of the material serves to ensure that Concrete Canvas is watertight.

Compared to traditional concrete solutions, the installation of Concrete Canvas is faster, easier and more cost-effective and provides the added benefit of reducing the environmental impact of concrete-making work by up to 95%.

Concrete Canvas is a unique product and very innovative because there is no such product before. Using materials consisting of cement, canvas, dry concrete mix, fiber plus some other ingredients, this product offers many benefits.

Concrete Canvas is easily mobilized, especially to the remote area, because it is in roll form. Transportation does not have to use large vehicles. If there is no access to small vehicles though, this product can be rolled by the workers.

Concrete Canvas is perfect for areas where transportation infrastructure is limited. Using this product does not require a mixer plant, concrete mixing machine or other specialized applicators. How to use it is not complicated. Anyone can do it. So, the concept is very simple.

How to use Concrete Canvas most easily. This product is in the form of rolls (rolls) that stayed open and stretched when about to be used. The installation position is adjusted to the needs and conditions of the field. In the connection section should be overlapping along the length of about 100 mm in order to really meetings.

.jpeg)

Once installed, Concrete Canvas is ready flushed with water. Water used is not necessarily clean water. Sea water and even water comberan can. The result is the same. After two hours, Concrete Canvas is set, hardened like concrete and ready to function.

Concrete Canvas Applications are 10 times faster than regular concrete concrete techniques and the results are not like sprayed concrete. No wonder Concrete Canvas is widely used for slope protection so that the soil does not slide and cover the drains. Concrete Canvas is also effectively used to coat regular concrete concrete that has been cracked or cracked. Stay coated only.

The durability of concrete canvas can be up to 40 years, and almost without treatment. As long as the foundations are strong, especially if they are dry, their endurance will last longer.

Below are some construction results from the use of concrete canvas.

.jpeg)

.jpeg)

.jpeg)

And much more use of concrete canvas. Maybe you can add in the comments. That's a little science about concrete canvas. Hopefully useful for myself and for readers. thank you.

References:

CERITA ENGINEER

konkrit kanvas