Steel is an alloy of iron and carbon and other elements. Steel has high tensile strength and low cost for production. because this reason, steel is used in any engineering application, such as major component used in buildings, infrastructure, tools, ships, automobiles, machines, appliances, and weapons.

Based on carbon contain as alloying element with iron, steel has 3 types. That is low, medium, and high carbon steel. This types of steel has different application. In this article, we will discuss of 3 types steel in engineering application.

1. Low Carbon Steel

The bridge use steel for main construction. [Image Source : unsplash.com]

Low Carbon Steel contains less than 0.25% wt carbon content. Among all the steel produced for various purposes, the low carbon steel group is produced with the greatest quality and covers a great diversity of shapes for engineering purpose. Low carbon steel can not be processed by heat treatment to form martensite phase. The process of strengthening by cold treatment process (cold working), the microstructure consists of ferrite and perlite phases.

This steel alloy is relatively soft and weak, but has best ductility and toughness. furthermore, this steel can be machineable, weldeable, and compared with all other types of steel, low carbon steel is the least expensive to produce.

This low carbon steel commonly used to Panels Automobiles, Nails, wires, Pipe, and Structures (bridges and buildings).

2. Medium Carbon Steel

Medium carbon steel has a carbon concentration between 0.25 - 0.6% wt. These steel alloys can heat treatment process by austenitizing, quenching, and then tempering in order to improve mechanical properties. The strength of hot-welded alloy steel is stronger than that of low carbon steel, but its ductility and toughness decreases. These alloys also have a combination of strength, wear resistance, and excellent toughness.

This steel has application in crankshaft, bolt, chisel, hammer, knife, hacksaw, spring, hand tools, bushings, pipes, shaft, piston gears, and other purpose for more mechanical properties (yield and tensile stregth) in uses.

3. Hgh Carbon Steel

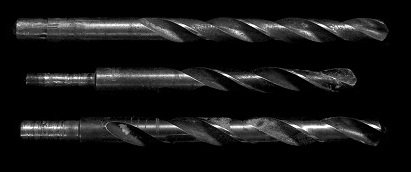

Drill tools is use to make a hole and use high carbon steel material. [Image Source : unsplash.com]

High carbon steels usually have a carbon content above 0.6% wt. This alloy steel is the hardest and strongest steel, but its toughness is least compared to other carbon steels. These carbon steels are almost always used in the aftermath of hardening and tempering. So this steel will be resistant to wear and can be used as a sharp cutting tool.

this steel has application in drill, saws, lathe tools, punching, molding, towing wire molds, cutting tool, pipe cutter, concrete drill.

Conclusions

Steel has different types based on carbon contain. In each type has variuos purpose to used beause any types has different mechanical properties, such as yield strength, tensile strenght, wear resistant, and etc. In example, high carbon steel can not used in structural, because the toughness is lower than low carbon steel.

One types steel can not for all purpose in engineering. So, choose the correct steel for the correct application for the great result in uses. I hope this simply article can useful for us.

Regards,

Mujahud

Congratulations @mujahud! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPCongratulations @mujahud! You received a personal award!

Click here to view your Board

Do not miss the last post from @steemitboard:

Congratulations @mujahud! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!