The 100 year clock

Clocks turn pretty slowly. I'm sure I'm not the only one that has stared intently at the minute or hour hand of an analogue clock trying to see its movement. Of course we all know that second hand will do a complete turn every minute, the minute hand every hour and the hour hand every 12 hours. But what if there were more hands? One that turned every month, or every year, or every century? I made a mechanical clock that does all those things.

Why?

Because no one else had.

Halfway through the pregnancy of my first child (and only child so far) I started to think through what I might buy as a present for my son when he was born. I wasn't interested in a kids teddy or toy, he would get plenty of them from others. I wanted to do something special. Something that would last and be more valuable when he was older. Maybe a bottle of wine? Maybe a bitcoin? Something more meaningful.

Somehow I came to the idea of a clock that would count his age. I thought surely that must exist somewhere. A clock that I could start ticking on his birthday, then when he was old enough to have his own house he could mount it on his wall and be reminded that I started it for him all those years ago. Ticking incessantly behind the scenes, through the night and while he played. Consistent and unrelenting.

But I couldn't find a clock that counted any more than 12 hours. There are millions of clocks that do that. Round and round only to reset and start again each night. Not gaining ground. No progress.

The closest thing I could find was this; https://theawesomer.com/100-year-clock/13317/

A nice project, but not for sale, questionable accuracy, and doesn't tell the time.

So I decided to make my own.

How?

Though I had originally planned to start from scratch, I came across a nice clock body in a little Australian hinterland store. It's big face and wide cavity behind the glass front made it a perfect starting point.

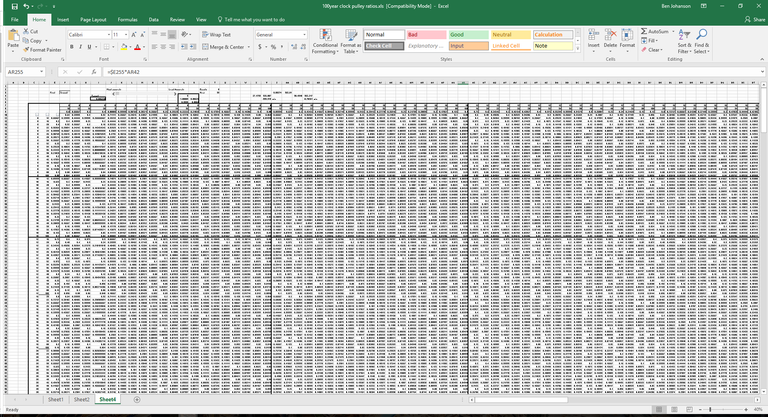

First I had to work out the gear ratios. I bought a bunch of plastic gears off ebay. Though there is a lot of sizes available, you can't get every combination of teeth. Which made the gear ratio tricky because I needed a very exact ratio, even one tooth out somewhere could result in weeks out of time after a few years. So I made a spreadsheet and put in all the gear sizes I had available, and it spit out the combinations that could get me there.

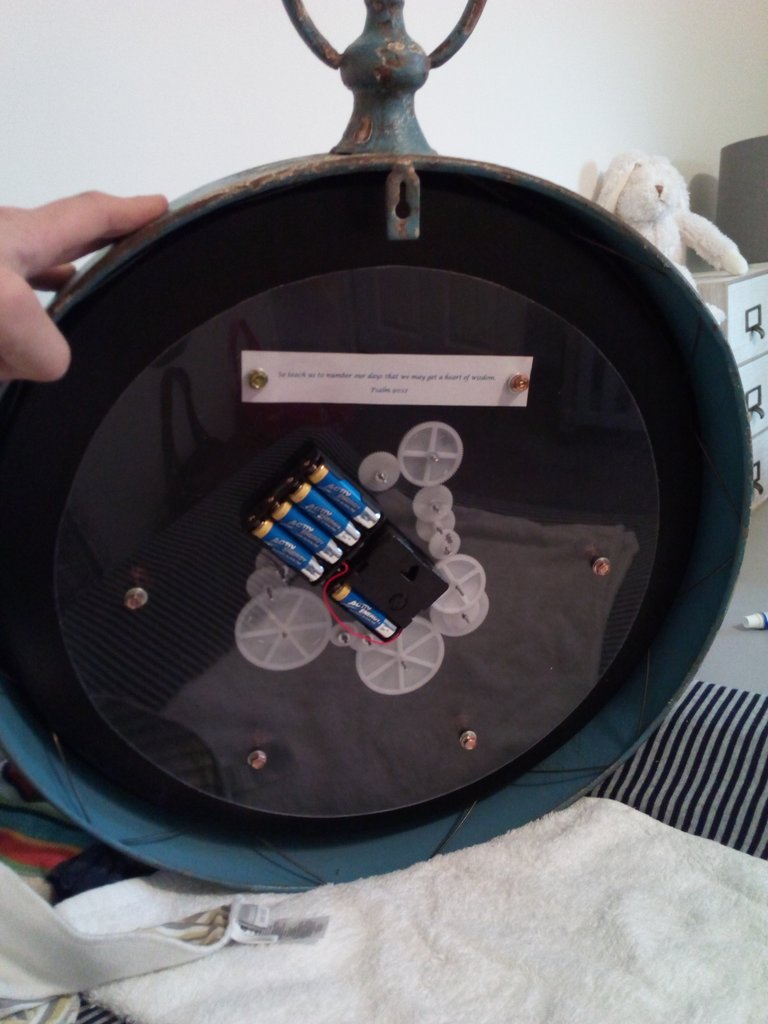

I replaced the clock's movement with a better quality, high torque quartz movement that had a longer nose leaving extra space to add some small plastic gears. I mounted the gears by nailing them to an acrylic sheet. This is a 14 stage gear reduction resulting in a total reduction ratio of 73050:1 driven by the hour hand of the clock mechanism.

I then mounted the acrylic sheet to the back of the clock and added in an extra battery set (wired in parallel) for extra long battery life.

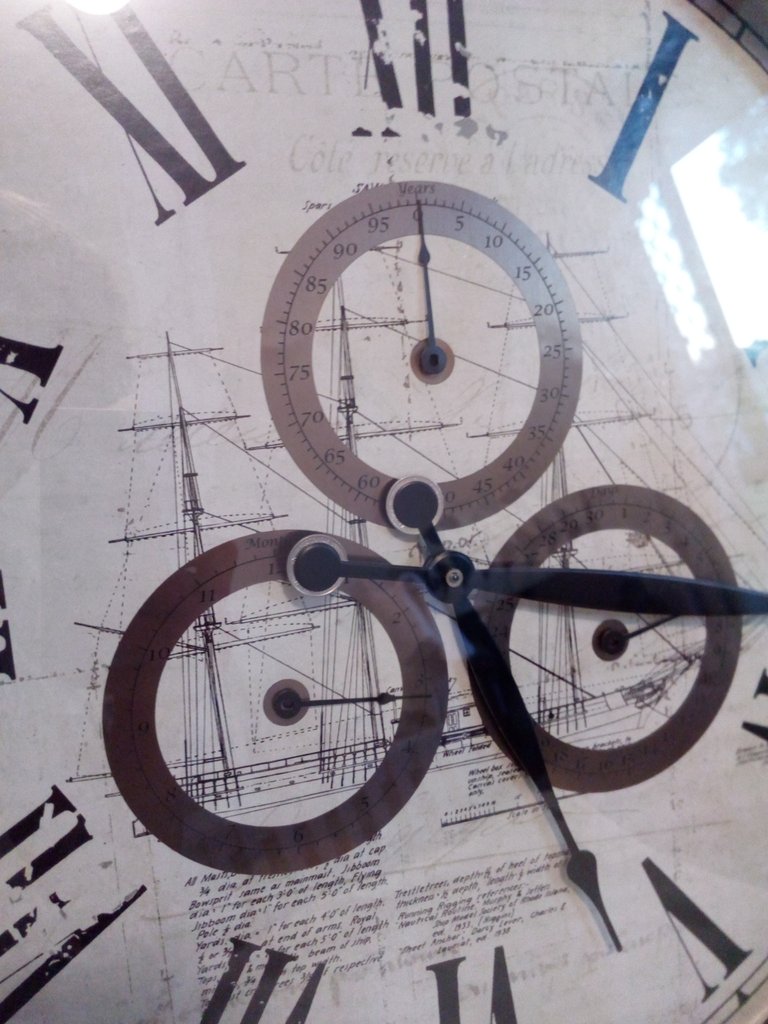

I drilled through the face of the clock, attached a shaft to the days/months/years cogs and attached the additional hands.

I modeled the dials and had them laser cut/etched into bronze tape at a local trophy shop then stuck them in place on the clock face.

And then I put it on the wall.

So far this clock has been running for over 15 months, and has been spot on time on every dial.

But what about....

The batteries running out - A normal analogue clock should last at least a year on a single AA battery. This one has 5 AA batteries and I balanced the weight of the hands with a couple little coins. So I expect it to last at least 5 years before I have to worry about it. Because the clock also has normal minute and hour hands, it should be fairly clear when the batteries start running out because the time will fall behind. Then I just need to replace the batteries and wind the clock forwards to the correct time. This will also adjust the other hands up to time provided that I haven't missed any days while the clock was dead.

Plastic gears wont last long - Maybe so. I looked into using brass gears but these were very very expensive for the sizes I needed. And brass also corrodes over time. My thinking is that wear won't be a problem because of the very very low speed and torques that are transferred. The overall number of turns will be much less than in other applications that use plastic gears such as toy cars etc running at over 100 rpm. As long as they don't get too hot or left out in the sun I think they should be OK.

Leap years - Yes these are accounted for. The year dial does exactly 365.25 turns per year.

I'm pretty happy with how this turned out and I hope it keeps ticking for many years to come.

I feel like I covered everything, if not here's a video with me running through it. Otherwise feel free to ask!

love the ships!

Congratulations @bengineering! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP