Welding is the process of joining two metals into one by heating the metal. Type of welding. Welding exists in every manufacturing industry. The welding process can be interpreted as a permanent connection that can not be separated with certain properties. The result of welding depends on the main factor. This is the melting point, thermal conductivity, thermal expansion, metal surface conditions, and changes in micro structure.

image source: https://shaikmoin.wordpress.com

The basis of welding can be grouped in 3 types:

1.Plastic Welding

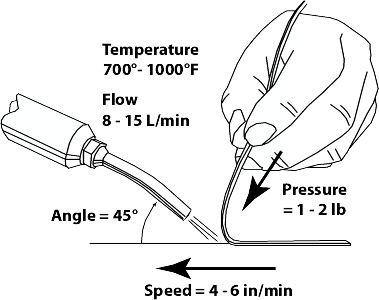

In the process of plastic welding or pressure welding, the pieces of metal to be joined will be preheated to the plastic or plastic properties then united in the external pressure. This welding process is called the liquid-solid welding process so that we can easily remember it. This procedure is required to forge the welding and welding resistance of the metal is feasible for use and good welding or not.

image source: https://www.polyvance.com

2.Welding Fusion

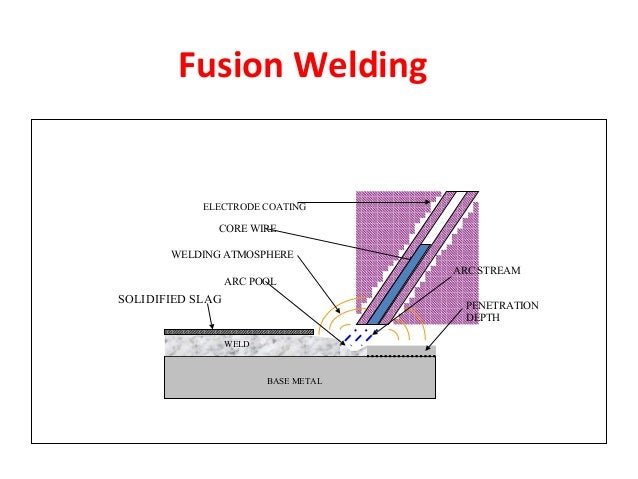

Fusion welding is better known as welding with non-pressure welding process, here described the welding process. Workpiece or metal, in a state of thaw first means melted herein the nature of the material or the state of the material and left aloud by itself. This is referred to as the liquid welding process. Contok welding liquid including gas welding, arc welding, and thermite welding.

image source: www.slideshare.net

3.Cold Welding

This welding process does not require heat, but this welding can apply pressure which can produce a fusion or molecular alloy with the surface of the joined portion, this welding can be called the solit state welding. This welding process is used in nonferrous metals. For example ultrasonic welding, friction welding, and explosive welding.

image source: https://www.wireweb.de