There are no clear picture for Multi V bending dies so we prepared the article to speak about all. Standard for all main Italian press brake tools producers are max. 4V dies for Promecam system. These are not the effective or best solution but very loved by all press brake suppliers to use the set of 1 punch and 1 x 4V die which could be used for different thicknesses. For customer it means the universality and flexibility - he can bend different thicknesses with only one die. So how it goes it most ways - customer buys 105 mm punch and 4V die with press brake and after the starting of the daily work customer tries to realize what he needs more.

What is not good with Multi-V dies? Differences in openings are too big so if you cares about specific radius and other parameters of bending with nearly thicknesses of materials it is recommended that you will buy standard single-V die specially for your job.

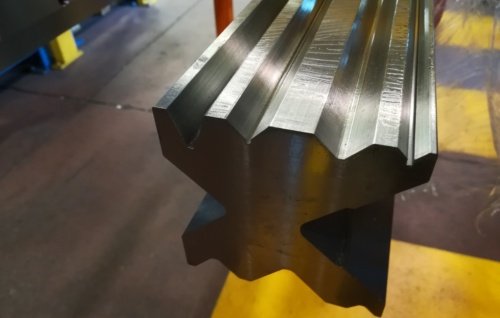

But the solution with Multi V should be more interested if there is the story about 8 or 10 openings on one die - this is usually used for Chinese and Taiwanese machines, Spanish and South America manufacturers etc. But it is important that the clamping for bottom tools can be used to clamp width like 90-95 mm, 110-115 mm etc. Moreover even if the customer wants it it is better to think twice if he really needs this die or just couple of standard single V types.

Why we also don't really like them? Because if the first one came from Asia with the cheapest quality and material, customer really doesn't want to pay more than 1000 eur/meter for new one. And attention, also to wait more than 4 weeks in case that standard T die could be shipped in 2-3 days.

Why any T-shape single die is more preferred for small openings than Multi-V. Just the configuration - if you have any return bends (both directions) you can also easily catch the collision with your Multi-V and will be limited with bends configuration.

Could be other question to use Multi-V for high tonnage and thicknesses, for example big openings and body of die 200*200 or more. This type of die for example on tandem of 12 meters with the possibility of fast rotation with lifting equipment can save a lot of money against several single V types. So in such cases there are big reasons to use configuration of Multi-V if possible with probably no any objections contrary.

Important to say that in Trumpf-Wila or Beyeler any Multi-V dies are never used. It is not projected to install according to the holder for tang and there is no technical or economical reason to look for the solution. So the reason of use obn other system came from the wish of the customer but it is necessary to justify the efficiency.