Step Five:

It's time to jump the cliff and engrave the full artwork. This is perhaps the hardest step in terms of financial risk. Those metal plates are freaking expensive and complex to set up.

My metal plate are made from high grade stainless steel, that's the only way to get vivid colors with the laser, I've tried dozen of steel / stainless combination.

Here are the metal plates specs:

- Film protected before cutting to avoid scratches.

- Laser cut to size to avoid cutting tools marks (The current plate was not laser cut).

- Sand blasted to remove any micro scratches and help to reflect the color better.

- Packed in sized bubble bags to keep them safe in the storage area.

All those modification makes any mistake from now on very painful ...

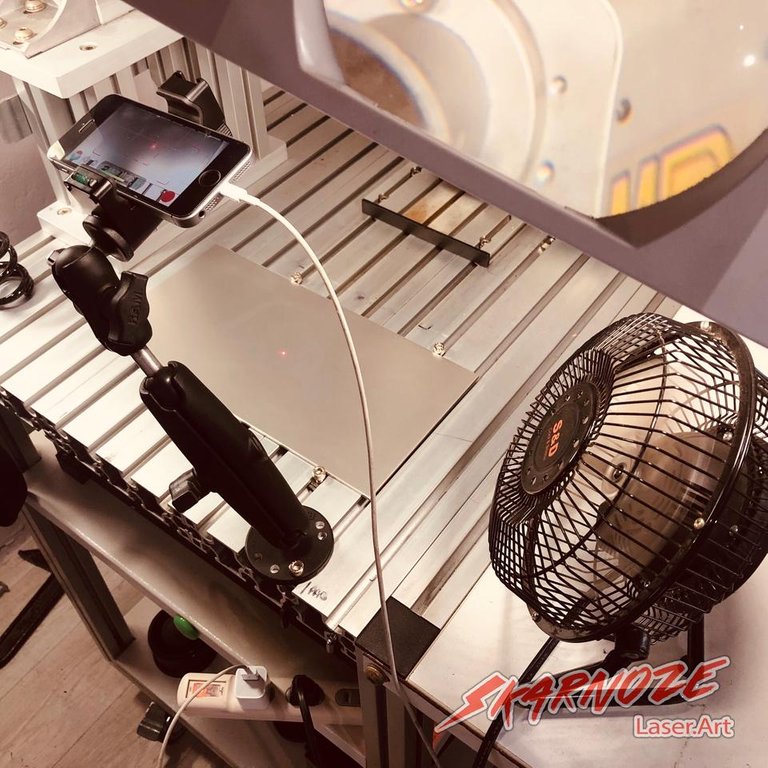

I need to carefully attach the plate to the laser table and use plastic gloves, any finger prints will alter the laser and stay there forever lol.

After a last check:

✅ Metal Plate firmly attached and clean : OK

✅ Laser Ready : OK

✅ Camera rolling : OK

✅ Lighting properly set : OK

Time to press the start button and see the magic happens :)

Follow this Project:

➡ Tribute to Karl Lagerfeld - Part 1 - The design

➡ Tribute to Karl Lagerfeld - Part 2 - Create Vectors on Illustrator

➡ Tribute to Karl Lagerfeld - Part 3 - Programming the Laser

➡ Tribute to Karl Lagerfeld - Part 4 - Let's make a sample

➡ Tribute to Karl Lagerfeld - Part 5 - Start the Laser Engraving

➡ Tribute to Karl Lagerfeld - Part 6 - Stunning Result !!!

Thanks a lot for reading,

SkarNoze

—————————————————————————

Follow my Laser Engraving Journey:

➡ https://steemit.com/@skarnoze

➡ https://www.facebook.com/SkarNoze/

➡ https://www.skarnoze.com

Congratulations @skarnoze! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board

If you no longer want to receive notifications, reply to this comment with the word

STOP